Preparation method for polymer fat-liquoring agent containing sulfosuccinate salt structure

A technology of sulfosuccinate and polymer, which is applied in the chemical treatment of small raw hides/large raw hides/leather hides/furs, animal husbandry, applications, etc. Problems such as low copolymerization activity of intermediates, to achieve good stability and reduce COD content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

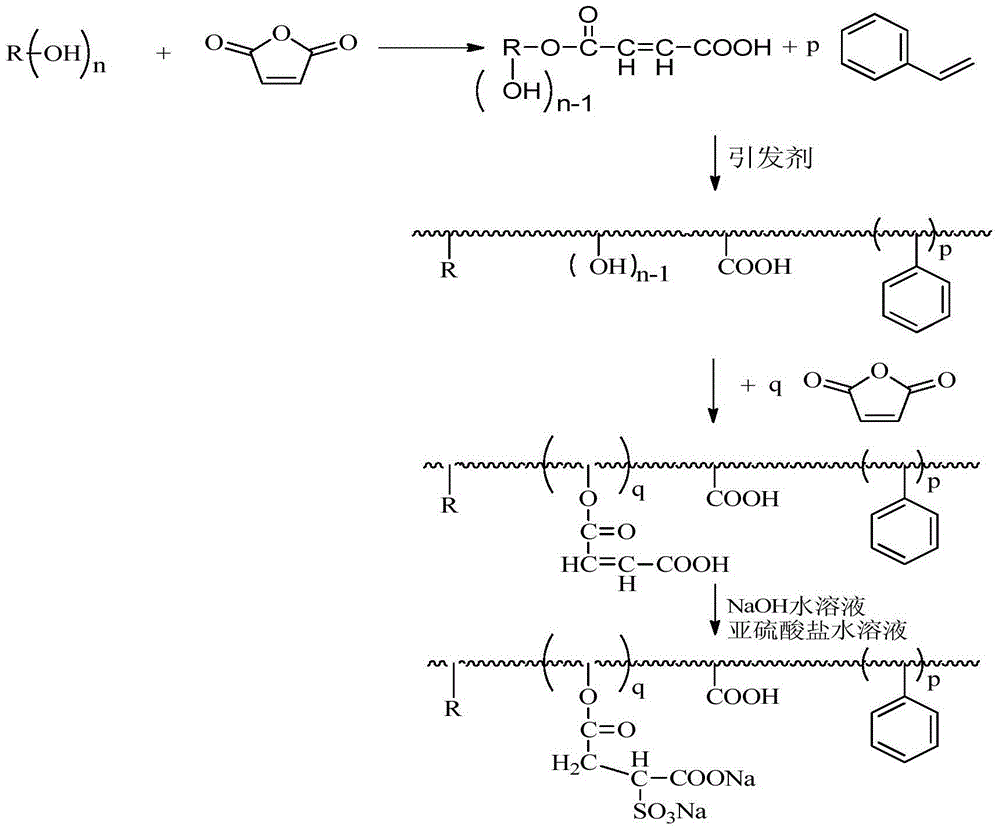

Method used

Image

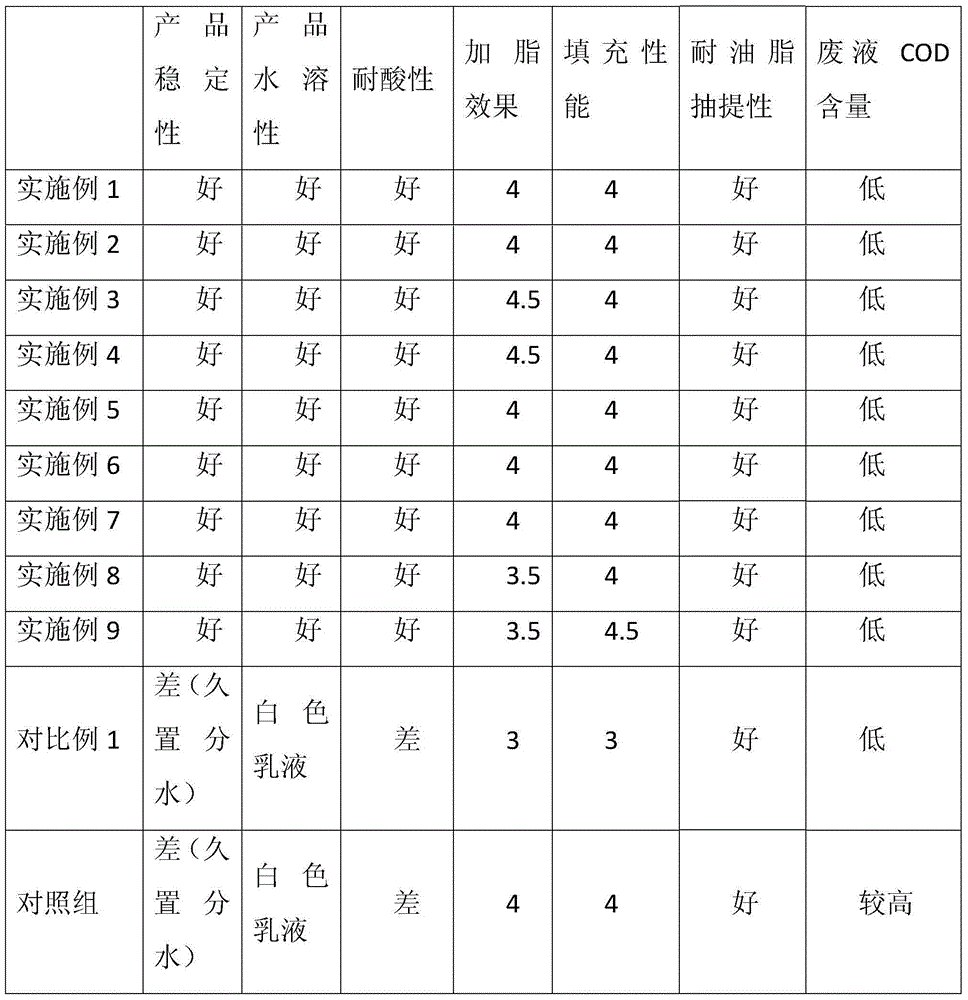

Examples

Embodiment 1

[0028] A preparation method of a polymer fatliquoring agent containing sulfosuccinate salt structure, specifically comprising the following steps:

[0029] (1) 1.0mol castor oil is added in the reactor, the temperature is raised to 60° C., 0.5mol maleic anhydride is dropped into, and the esterification reaction is carried out for 3 hours to obtain intermediate A;

[0030] (2) Add 0.065g initiator AIBN to intermediate A, drop 0.5mol styrene within 15 minutes, keep the reactor temperature at 70°C, add 0.065g AIBN every 30 minutes, add 3 times altogether, Last insulation 55min, obtain polymer B;

[0031] (3) Add 2.5mol maleic anhydride to polymer B, and react at 70°C for 3 hours to obtain polymer C;

[0032] (4) Cool the polymer C to 60°C, adjust the pH to 6.5 with a 30% NaOH aqueous solution, add 1000g of a 30% aqueous sodium sulfite solution, heat up to 80°C and react for 3 hours. Polymer fatliquoring agent with succinate salt structure.

Embodiment 2

[0034] A preparation method of a polymer fatliquoring agent containing sulfosuccinate salt structure, specifically comprising the following steps:

[0035] (1) Add 0.1mol castor oil to the reactor, heat up to 90°C, drop in 0.15mol maleic anhydride, react for 6 hours, and obtain intermediate A;

[0036] (2) Add 0.81g initiator AIBN to intermediate A, drop 1.5mol methacrylic acid in 45 minutes, keep the temperature of the reactor at 90°C, add 0.81g AIBN every 60 minutes, and add 7 time, and finally keep warm for 65min to obtain polymer B;

[0037] (3) Add 0.15mol maleic anhydride to polymer B, and react at 90°C for 6h to obtain polymer C;

[0038] (4) Cool the polymer C to 70°C, adjust the pH to 7.5 with a 30% NaOH aqueous solution, add 100 g of a 30% sodium metabisulfite aqueous solution, heat up to 90°C and react for 5 hours, and cool down to obtain the Polymer fatliquoring agent with succinate salt structure.

Embodiment 3

[0040] A preparation method of a polymer fatliquoring agent containing sulfosuccinate salt structure, specifically comprising the following steps:

[0041] (1) Add 0.1mol castor oil and 0.1mol glycerol monooleate into the reactor, heat up to 80°C, drop in 0.2mol itaconic anhydride, react for 5 hours, and obtain intermediate A;

[0042] (2) Add 0.42g initiator AIBN to intermediate A, add 0.5mol methacrylic acid and 0.5mol stearyl methacrylate dropwise within 30 minutes, keep the temperature of the reactor at 85°C, and add it every 45 minutes 0.42g of initiator AIBN was added 4 times in total, and finally kept warm for 60min to obtain polymer B;

[0043] (3) Add 0.3 mol of maleic anhydride to polymer B, and react at 80° C. for 4 hours to obtain polymer C;

[0044] (4) Cool the polymer C to 65°C and adjust the pH to 7.0 with a 30% NaOH aqueous solution by mass fraction, add 88.2g of a 30% aqueous sodium sulfite solution, heat up to 85°C and react for 4 hours. Polymer fatliquoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com