Processing method of aniline intermediate production wastewater

A treatment method and technology for producing wastewater, which can be used in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as affecting the quality of salt crystals and blocking pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

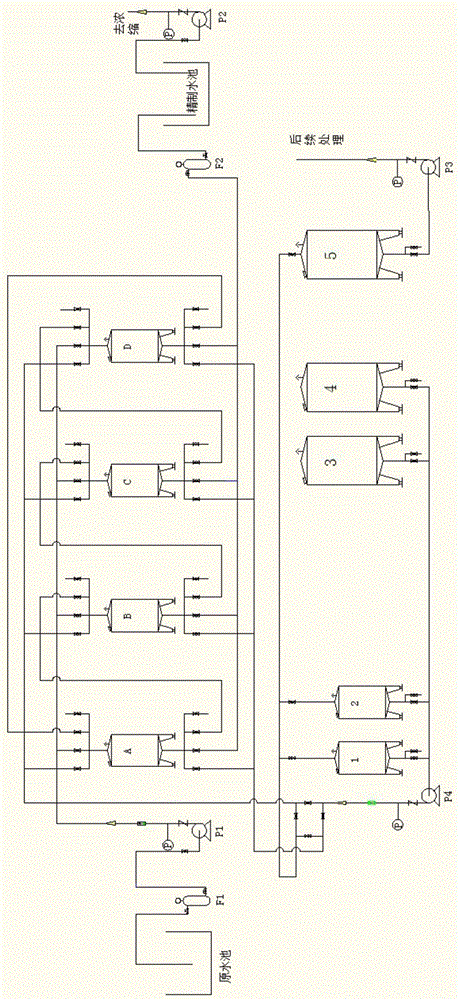

[0055] The waste water is m-acetamido-N, N-diethylaniline synthesis wastewater (m-amino acetanilide and ethyl chloride undergo an alkylation reaction in the presence of ammonia water to produce waste water containing ammonium chloride), and the microfilter is equipped with a 50-micron filter The macroporous resin packed in the resin columns in the adsorption towers A~D is DA201-C resin, and the volume of the resin column is 4m 3 , waste water with 12m 3 The adsorption tower reaches saturation in 10 hours at a flow rate of / h, and the desorbent is 90% methanol. 3 / h flow rate washing or desorption for 1 hour, the specific steps are as follows:

[0056] 1) Collect the wastewater into the raw water pool, adjust the pH to 6.8-7.0, filter through the microfilter, and pump it into the resin adsorption device with three ABC towers in series (4 towers and 3 in series, D tower for standby) for adsorption operation;

[0057] 2) After the A adsorption tower is saturated, the feed is st...

Embodiment 2

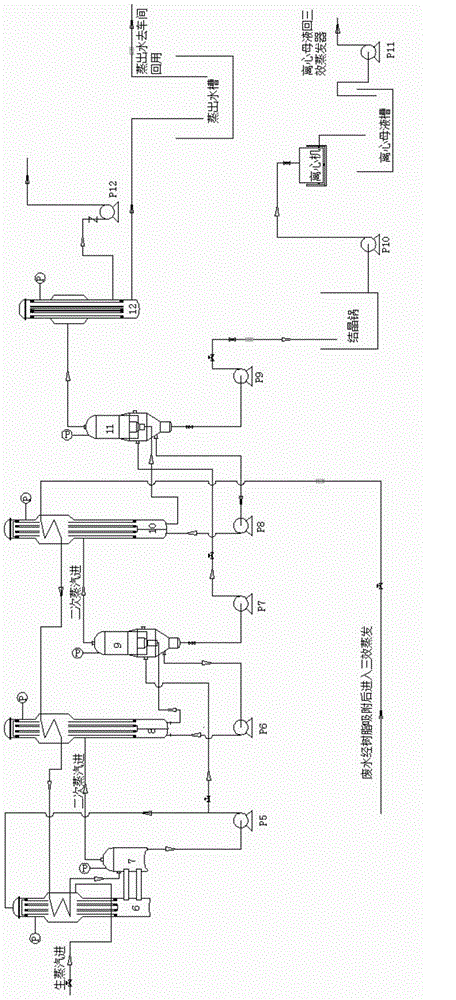

[0066] 2-methoxy-5-acetamido-N, N-diallylaniline synthetic wastewater (2-methoxy-5-acetamidoaniline and allyl chloride undergo alkylation reaction in the presence of ammonia water will produce chlorinated Ammonium waste water) is operated by the method described in embodiment 1, and difference is: waste water is adjusted pH5.0 with hydrochloric acid earlier, and waste water is with 10m 3 / h flow rate adsorption for 10 hours, desorbent is 10% hydrochloric acid, water and desorbent are 6m 3 / h flow rate washing or desorption for 1 hour, the analysis solution in the analysis solution recovery tank is used for the synthesis of subsequent dyes; when the three-effect evaporation is set, the first effect temperature is 90°C, the first effect vacuum degree is -40KPa, and the second effect temperature is 80 ℃, second effect vacuum degree -60KPa, third effect temperature 65℃, third effect vacuum degree -85KPa. The obtained ammonium chloride had a yield of 99.5% and a purity of 99.3%. ...

Embodiment 3

[0068] 2-cyano-4-nitroaniline synthesis waste water (2-cyano-4-nitrochlorinated benzene and liquid ammonia ammonolysis reaction can produce waste water containing ammonium chloride) by the method described in Example 1, The difference is: waste water is 16m 3 / h flow rate adsorption for 10 hours, the desorbent is 95% methanol, and the water and desorbent are 8m 3 / h flow rate washing or desorption for 1 hour; when three-effect evaporation, set the first effect temperature to 98°C, the first effect vacuum degree to -36KPa, the second effect temperature to 75°C, the second effect vacuum degree to -62KPa, and the third effect temperature to 68 ℃, third effect vacuum -88KPa. The obtained ammonium chloride has a yield of 99.6%, a purity of 99.1%, and a recovery of 2-cyano-4-nitroaniline of 64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com