Bimetal composite pipe both-side welding process

A bimetallic composite pipe, double-sided welding technology, applied in metal processing equipment, welding equipment, manufacturing tools and other directions, can solve the problems of high cost and low welding efficiency, and achieve the reduction of welding material cost, the improvement of welding efficiency, and the improvement of welding efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The specification of the bimetal composite pipe is Φ914.4mm×68mm. The base material is ASTM A671CC65 carbon steel of ASTM standard. The corrosion-resistant inner lining is UNS N06625 nickel-based alloy, and the thickness of the inner lining is 3mm. The main operation steps are as follows:

[0042] 1. Preparation process before welding:

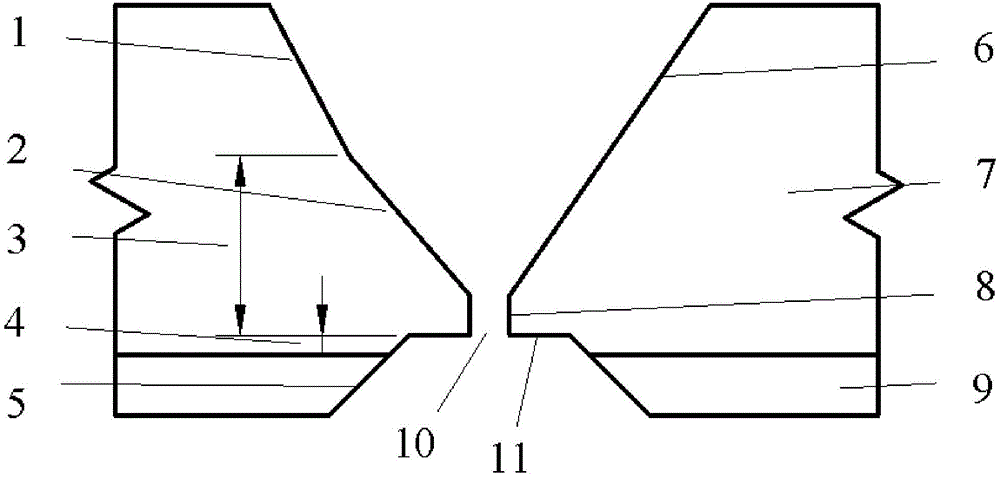

[0043] 1) Groove production: use the method of machining + grinding to process double-sided composite grooves. The structure of double-sided composite grooves is as follows: figure 1 shown. One side of the outer groove located on the side of the carbon steel matrix 7 is a single-V composite groove with a lower groove slope 2 of 35 degrees, an upper groove slope 1 of 10 degrees, and the other side with a slope 6 of 30 degrees. The blunt edge 8 of the single-V composite groove is 2mm, the groove gap 10 is 3mm, the connection between the lower groove and the upper groove on the outer groove side is the inflection point, and the vertical ...

Embodiment 2

[0072] The specification of the bimetallic composite pipe is Φ965.2mm×70mm. The base material is ISO3183L450 carbon steel according to ISO standard, the corrosion-resistant inner lining is UNS N06625 nickel-based alloy, and the thickness of the corrosion-resistant inner lining is 4mm. The operation steps are as follows:

[0073] 1. Preparation process before welding:

[0074] 1) Groove production: use the method of machining + grinding to process double-sided composite grooves. The structure of double-sided composite grooves is as follows: figure 1 shown. One side of the outer groove located on the side of the carbon steel matrix 7 is a single-V compound groove with a slope 2 of the lower groove of 40 degrees, a slope 1 of the upper groove of 12.5 degrees, and a slope 6 of the other side of 32.5 degrees. The blunt edge 8 of the single-V composite groove is 3mm, the groove gap 10 is 4mm, the connection between the lower groove and the upper groove on the outer groove side is ...

Embodiment 3

[0103] The specification of bimetallic composite pipe is Φ1016mm×75mm, in which the carbon steel substrate is API 5L X65 carbon steel adopting API standard, the corrosion-resistant inner lining is UNS N06625 nickel-based alloy, and the thickness of the corrosion-resistant inner lining is 5mm; the operation steps are as follows:

[0104] 1. Preparation process before welding:

[0105] 1) Groove production: use the method of machining + grinding to process double-sided composite grooves. The structure of double-sided composite grooves is as follows: figure 1 shown. One side of the outer groove located on the side of the carbon steel matrix 7 is a single-V compound groove with a slope 2 of the lower groove of 40 degrees, a slope 1 of the upper groove of 12.5 degrees, and a slope 6 of the other side of 32.5 degrees. The blunt edge 8 of the single-V composite groove is 3mm, the groove gap 10 is 5mm, the connection between the lower groove and the upper groove on the outer groove s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com