Fragrant warming paste containing plant essential oil and manufacturing method thereof

A plant essential oil and aroma technology, which is applied in the field of daily necessities, can solve the problems of high consumption of plant essential oil or liquid spices, high volatility, poor aroma effect, and large raw material loading, so as to avoid heating stability, reduce volatilization and consumption, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Paste-type aromatic warm patch prepared by jasmine essential oil

[0055] Take pure jasmine essential oil and dilute it with 95% ethanol at a volume ratio of 1:20, slowly dissolve the diluted jasmine essential oil in a volume ratio of 1:10 in a saturated aqueous solution of β-cyclodextrin (at 30°C), and dissolve for 1 hour while stirring. After refrigerating for 24 hours, filter and wash with distilled water. After drying at a low temperature of 40°C, pass through a 100-mesh sieve, and use it as a powder spice in the raw material layer for subsequent use.

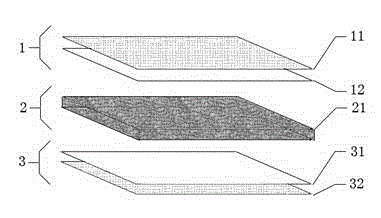

[0056] Such as image 3 As shown, the powdered fragrance prepared in the previous step is used as the powdered fragrance 21, and the self-heating agent 23 is respectively filled on both sides of the microporous air-permeable membrane 22, and the powdered fragrance 21 is adjusted to 5 g, and the outer side of the powdered fragrance 21 is a composite non-woven fabric Layer 1, the outer side of self-heating agent 23...

Embodiment 2

[0059] Non-sticky aromatic warming patch made with ylang ylang essential oil

[0060] Take 500g of β-cyclodextrin and 2 to 5 times the amount of distilled water, put it in a colloid mill and grind it evenly, then add 600ml of 10% ethanol solution of ylang-ylang ylang-ylang essential oil, and grind it with a colloid mill to form a paste. After being dried in a constant temperature oven at 50°C, pass through an 80-mesh sieve, and use it as the powder spice in the raw material layer for subsequent use.

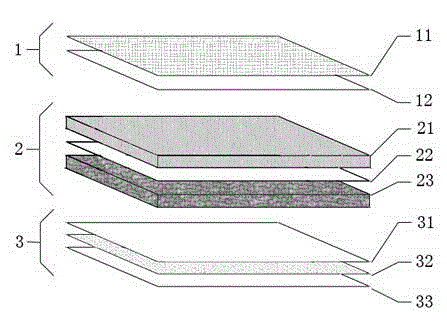

[0061] Such as Figure 4 As shown, the powdered fragrance prepared in the previous step is used as the powdered fragrance 21, and the self-heating agent 23 is respectively filled on both sides of the microporous air-permeable membrane 22, and the powdered fragrance 21 is adjusted to 5 g, and the outer side of the powdered fragrance 21 is a composite non-woven fabric Layer 1, the outer side of self-heating agent 23 is a composite non-woven layer 3, the edges are pressed by a he...

Embodiment 3

[0064] Non-sticky aromatic warming patch made with lemon essential oil

[0065] Take 500g of β-cyclodextrin and 10L of distilled water, ultrasonically dissolve it with an ultrasonic cleaner, add 100ml of 50% ethanol solution of lemon essential oil, and continue ultrasonication for 1 hour, so that the lemon essential oil is fully clathrated by cyclodextrin. Refrigerate at low temperature (0-5°C) for 24 hours, then filter, dry under reduced pressure at 40°C, pass through a 80-mesh sieve, and use it as a powder spice in the raw material layer for later use.

[0066] Such as Figure 5 As shown, the powder fragrance prepared in the previous step is used as powder fragrance 21 and powder fragrance 25, and is filled on both sides of the microporous gas permeable film 22 and the microporous gas permeable film 24 respectively, and the self-heating agent 23 is filled on the microporous gas permeable film 22 and the microporous gas permeable film 22 and the microporous gas permeable fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com