Herbicide formed by mixing pendimethalin with pyrithiobac-sodium and oxyfluorfen

A technology of pendimethalin and oxyfluorfen, applied in the field of pesticides, can solve the problems of influence of cotton safety, increased use cost, increased processing time, etc., and achieves improved storage stability, improved pulverization efficiency, and improved flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

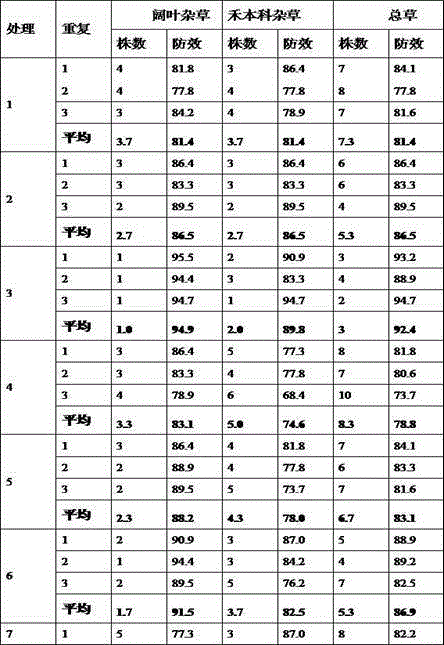

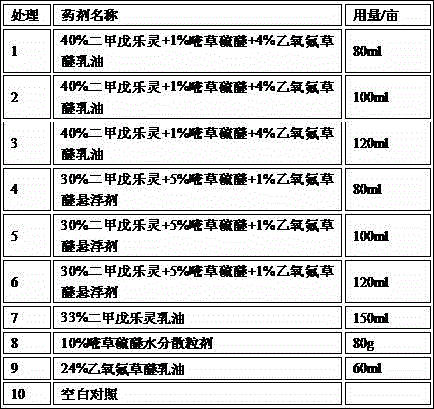

Examples

Embodiment 1

[0023] Pyrimicarb 1%

[0024] Pendimethalin 40%

[0025] Oxyfluorfen 4%

[0026] Emulsifier (non-ionic sulfate or phosphate) 15%

[0027] Solvent (methanol) make up 100%

[0028] Add the above-mentioned components into the reaction kettle in order of solvent, pyriflume, pendimethalin, oxyflufen, and emulsifier, dissolve completely and mix well to obtain the emulsifiable concentrate. Carry out the analysis and detection of various indicators.

Embodiment 2

[0030] Pyrimicarb 5%

[0031] Pendimethalin 30%

[0032] Oxyfluorfen 1%

[0033] Dispersant (lignosulfonate) 3%

[0034] Wetting agent (alkyl sulfonate) 2%

[0035] Thickener (methyl cellulose) 0.2%

[0036] Antifreeze (Ethylene Glycol) 5%

[0037] Defoamer (isopropanol) 2%

[0038] Deionized water makes up 100%

[0039] Put the above components into the sand mill in the order of pyrifluzal, pendimethalin, oxyfluorfen, dispersant, wetting agent, deionized water, and glass beads, and turn on the cooling water for grinding . Soak the thickener with antifreeze while grinding. When the grinding particle size reaches 3~5μm, add the soaked thickener and antifreeze mixture, add defoamer and mix well, then stop the sand mill. Filter and remove the glass beads to obtain the suspending agent. Carry out the analysis and detection of various indicators.

Embodiment 3

[0041] Pyrimicarb 20%

[0042] Pendimethalin 20%

[0043] Oxyfluorfen 20%

[0044] Dispersant (sodium dodecylbenzenesulfonate) 6%

[0045] Wetting agent Naphthalene sulfonate 2%

[0046] Carrier make up 100%

[0047] Accurately weigh the above raw materials, add them into the mixer, and mix them evenly. Start the jet mill, add the above-mentioned mixed raw materials into the jet mill for pulverization, add the pulverized materials into the mixer for remixing, and obtain wettable powder. Carry out the analysis and detection of various indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com