A MEMS microphone and a formation method thereof

A microphone and substrate technology, applied in the field of MEMS microphone and its formation, can solve the problems of CMOS circuit manufacturing obstacles, increased manufacturing cost, complicated circuit and microphone structure and process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

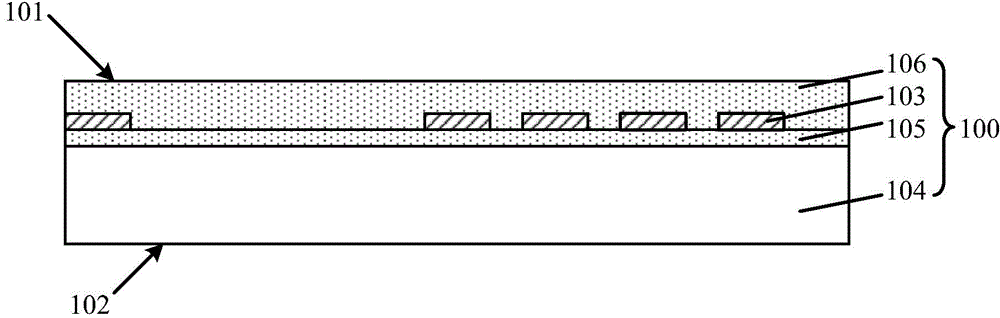

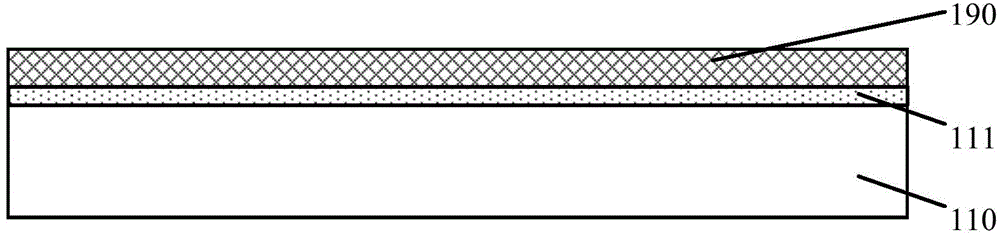

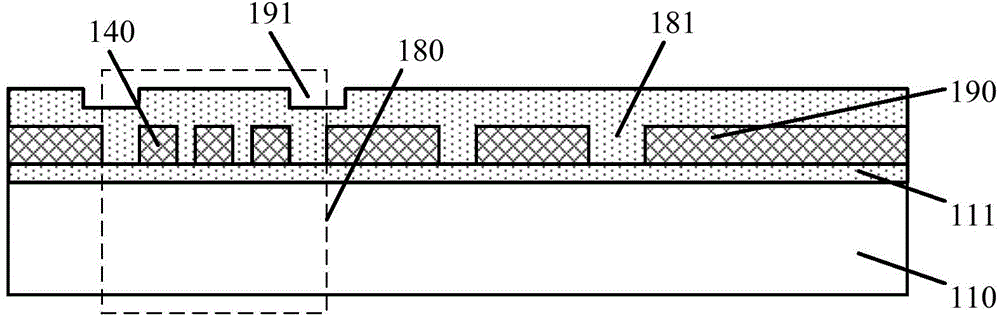

[0106] Figure 1 to Figure 9 It is a schematic cross-sectional structure diagram of the forming process of the MEMS microphone of the embodiment of the present invention.

[0107] Please refer to figure 1 , providing a first substrate 100, the first substrate 100 includes an opposite first surface 101 and a second surface 102, the first substrate 100 includes at least one conductive layer 103, and the conductive layer 103 is located at the The side of the first surface 101 of the first substrate 100 described above.

[0108] The first substrate 100 is used to form a conductive layer 103, and the conductive layer 103 is used to transmit electrical signals output by the sensitive electrodes.

[0109] In this embodiment, the first substrate 100 includes a first substrate 104, a first dielectric layer 105 located on the surface of the first substrate 104, and a conductive layer 103 located on the surface of the first dielectric layer 105; the first substrate 100 It also includ...

Embodiment 2

[0192] Figure 11 to Figure 12 is a schematic cross-sectional structure diagram of the forming process of the MEMS microphone according to another embodiment of the present invention.

[0193] Please refer to Figure 11 , providing a first substrate 200, the first substrate 200 includes an opposite first surface 201 and a second surface 202, the first substrate 200 includes at least one conductive layer 203, and the conductive layer 203 is located at the On the side of the first surface 201 of the first substrate 200 , the first substrate 200 further includes a self-test electrode 230 .

[0194] In an embodiment, the first substrate 200 further includes a circuit, and the circuit includes a semiconductor device structure and an electrical interconnection structure, and the conductive layer 203 may be a part of the conductive layer of the circuit, or may be on the circuit additional conductive layer. The conductive layer may include a conductor or a semiconductor.

[0195] ...

Embodiment 3

[0224] Figure 13 to Figure 14 is a schematic cross-sectional structure diagram of the forming process of the MEMS microphone according to another embodiment of the present invention.

[0225] Please refer to Figure 13 , providing a second substrate 314, the second substrate 314 includes an opposite third surface 318 and a fourth surface 319, the second substrate 314 includes a second base 310 and a sensitive electrode located on the second base 310 313 , the second substrate 314 includes a sensitive region 380 , the sensitive electrode 313 is located in the sensitive region 380 , and the sensitive electrode 313 is located on the third surface 318 side of the second substrate 314 .

[0226] In this embodiment, it also includes: forming a material layer 383 on the third surface 318 side of the second substrate 314; the second substrate 314 also includes a first electrode layer 312 on the second base 310, the The first electrode layer 312 includes the sensitive electrode 313 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com