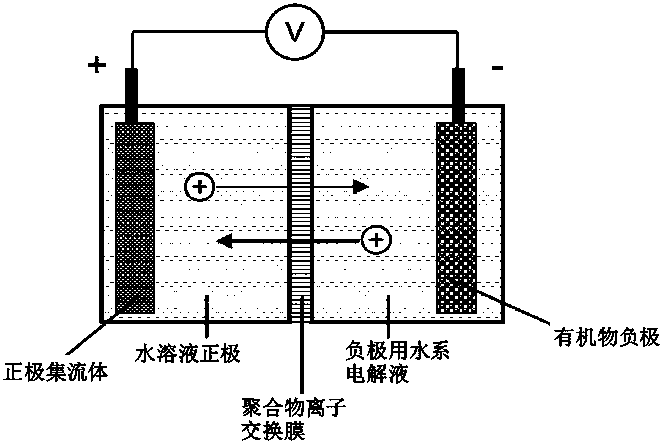

Aqueous lithium-ion/sodium-ion battery based on iodide ion solution positive electrode and organic material negative electrode

A sodium-ion battery, lithium-ion technology, applied in the field of electrochemistry, can solve problems such as increasing the cost of battery production, and achieve the effects of good electrochemical performance, low price, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

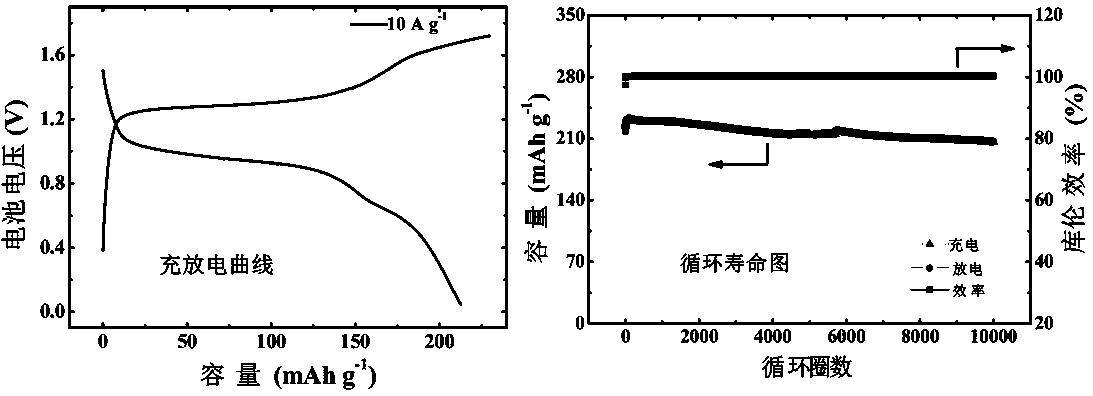

[0031] Example 1: Based on organic negative electrode anthraquinone (AQ, C 14 h 8 o 2 ) and an aqueous lithium-ion battery with an iodide ion solution positive electrode.

[0032] C 14 h 8 o 2 Molecular formula:

[0033]

[0034] First, the organic compound anthraquinone (AQ) is used as the negative electrode active material. The preparation of the negative electrode sheet is as follows: mix the slurry according to the ratio of active material (AQ): conductive agent (acetylene black): binder (polytetrafluoroethylene PTFE) = 60:30:10 to prepare a film electrode, and then The membrane electrode with a certain quality is evenly pressed on the stainless steel current collector to form the negative electrode sheet. In this example, the coating amount of the negative electrode was 6 mg cm -2 . Secondly, to contain 1.5 ml containing 0.01M I 2 , 0.1M LiI and 1M LiNO 3 The solution phase is the positive active material. The preparation of the positive current collector ...

Embodiment 2

[0035] Example 2: Based on organic negative electrode anthraquinone (AQ, C 14 h 8 o 2 ) and an aqueous sodium-ion battery with an iodide ion solution positive electrode.

[0036] C 14 h 8 o 2 Molecular formula:

[0037]

[0038] First, the organic compound anthraquinone (AQ) is used as the negative electrode active material. The preparation of the negative electrode sheet is as follows: mix the slurry according to the ratio of active material (AQ): conductive agent (acetylene black): binder (polytetrafluoroethylene PTFE) = 60:30:10 to prepare a film electrode, and then The membrane electrode with a certain quality is evenly pressed on the stainless steel current collector to form the negative electrode sheet. In this example, the coating amount of the negative electrode was 6 mg cm -2 . Secondly, to contain 1.5 ml containing 0.01M I 2 , 0.1M NaI and 1M NaNO 3 The solution phase is the positive active material. The preparation of the positive current collector i...

Embodiment 3

[0039] Example 3: Based on organic negative electrode 1,4-dihydroxyanthraquinone (DHAQ, C 14 h 8 o 4 ) and an aqueous lithium-ion battery with an iodide ion solution positive electrode.

[0040] C 14 h 8 o 4 Molecular formula:

[0041]

[0042] First, the organic substance 1,4-dihydroxyanthraquinone (DHAQ) is used as the negative electrode active material. The preparation of the negative electrode sheet is as follows: mix the slurry according to the ratio of active material (DHAQ): conductive agent (acetylene black): binder (polytetrafluoroethylene PTFE) = 60:30:10 to prepare a film electrode, and then The membrane electrode with a certain quality is evenly pressed on the stainless steel current collector to form the negative electrode sheet. In this example, the coating amount of the negative electrode was 6 mg cm -2 . Secondly, to contain 1.5 ml containing 0.01M I 2 , 0.1MLiI and 1M LiNO 3 The solution phase is the positive active material. The preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com