Preparation method of thin steel wire longitudinal sectional electronic microscopic sample

A technology of transmission electron microscope and thin steel wire, which is applied in the field of preparation of longitudinal section samples of thin steel wire transmission electron microscope, can solve the problems of difficult fine operation, affecting the reliability of analysis results, amorphous structure, etc., and achieve high sample preparation success rate, Low cost, effect of increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

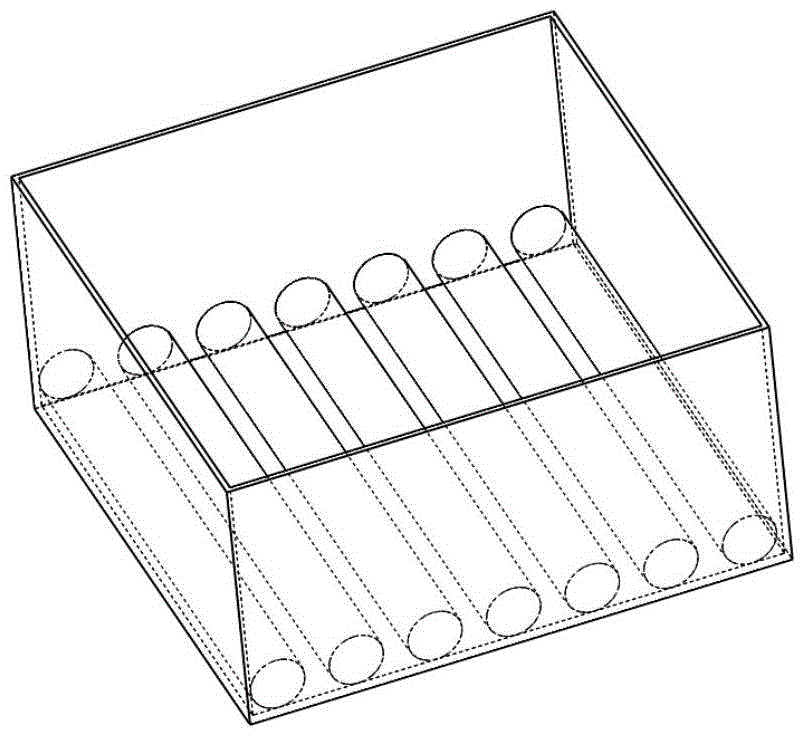

[0020] The present invention will be further described below in conjunction with embodiment, and the schematic diagram that the sample is equidistantly tiled in the bottom flat mold is as follows figure 1 shown, but the examples should not be construed as limiting the invention.

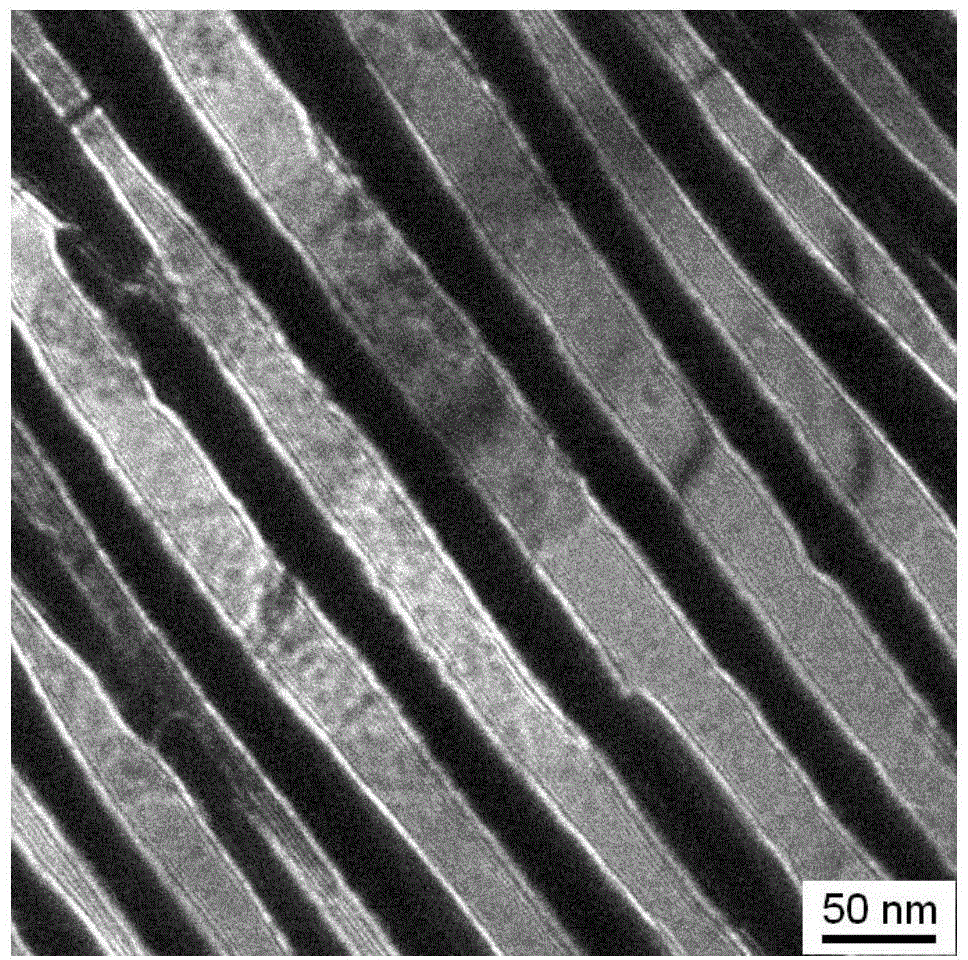

[0021] (1) The sample is a drawn 82B high-carbon steel fine steel wire with a diameter of 0.8 mm and a structure of sorbite. The sample is cut into 5 initial samples with a length of 5-10 mm by a vise.

[0022] (2) Use the glued paper on the back of the waste sandpaper as the material, and cut it into figure 1 The open mold shown is 10mm x 10mm x 5mm in size, make sure the bottom of the mold is flat. Mix the cold mounting resin and curing agent at a ratio of 7:1 and stir slowly. The stirring speed should be such that no air bubbles are generated in the liquid. Take about 0.5mL and inject it into the mold. Spread on the bottom of the mold, the distance between each initial sample should be controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com