Fabrication method of electrically injected silicon-based iii-v nanolaser array

A nano-laser, III-V technology, applied in the field of optoelectronics, can solve the problems of difficult to prepare metal electrodes, small device size, and difficult to achieve electro-laser lasing, and achieve low manufacturing cost, improved quality factor, and easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The disclosure provides a method for preparing an electrical injection silicon-based III-V nanometer laser array, which has a simple process, is easy to implement, and has low manufacturing cost. The preparation method of the electrical injection silicon-based III-V nano-laser array comprises:

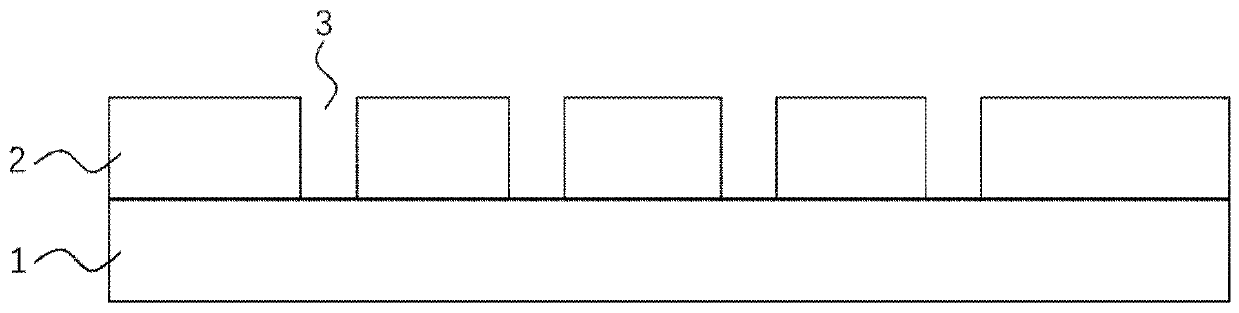

[0047] Deposit silicon dioxide on the SOI substrate, and etch periodic rectangular grooves on the deposited silicon dioxide;

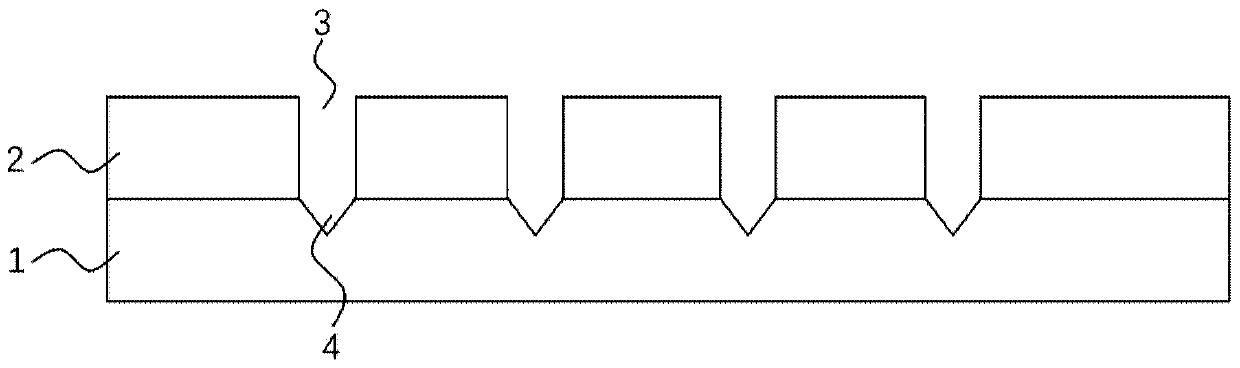

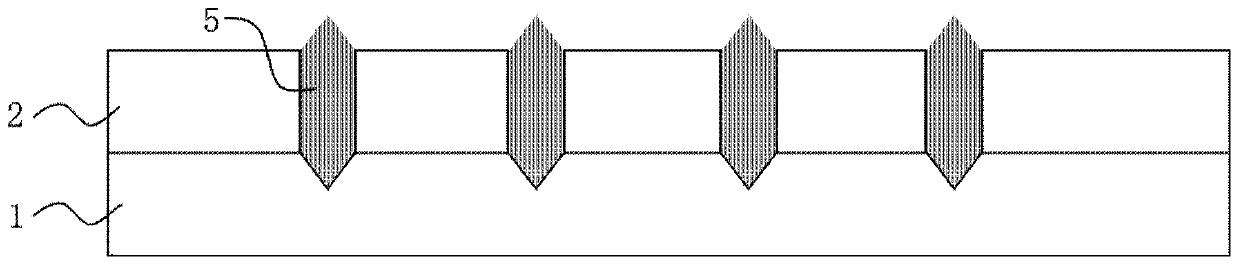

[0048] Etching the SOI substrate, etching a V-shaped groove under the rectangular groove; growing a III-V laser epitaxial structure in the V-shaped groove and the rectangular groove; Polishing the top of the laser epitaxial structure; etching the III-V laser epitaxial structure and the silicon dioxide on both sides to form an FP cavity in the direction along the trench extension; depositing a silicon dioxide isolation layer, and etching away the FP The silicon dioxide isolation layer outside the end face of the cavity, so that the silicon dioxide isolatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com