Biological energy absorption method and air energy heat pump system based on same

An air-energy heat pump and bio-energy technology, which is applied in air conditioning systems, heat pumps, space heating and ventilation, etc., can solve the problems of a large impact on breeding costs, and achieve the effect of improving power output and making good use of it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

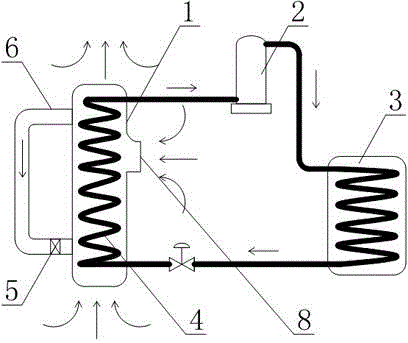

[0026] Such as figure 1 As shown, a bioenergy absorption method and an air energy heat pump system based on the method provide a bioenergy absorption method. The heat energy of the heat pump is absorbed and utilized. The heat absorption section of the heat pump is divided into two parts: the low-grade heat energy absorption part at the front end and the high-grade heat energy absorption part at the rear end. The heat carrier in the low-grade heat energy absorption part absorbs the natural environment When the heat carrier flows through the high-grade heat energy absorption part, the heat carrier exchanges heat with the airflow in the exhaust pipe or the ventilation port.

[0027] At the same time, the present invention provides an air energy heat pump system based on this bioenergy absorption method: the system includes a heat pump, and the heat pump includes a compressor 2, a condenser 3 and an evaporator 4 connected in sequence through pipelines, and the evaporator The outl...

Embodiment 2

[0032] The present embodiment is further limited on the basis of embodiment 1, as figure 1 with figure 2 As shown, after the airflow in the exhaust pipe or the air exchange port completes the heat exchange with the heat carrier in the high-grade heat energy absorption part, all or part of it is introduced into the heat absorption section of the heat pump once or multiple times for further heat exchange .

[0033] The above further limitation to the bioenergy absorption method in embodiment 1 facilitates the heat of exhaust gas in as many exhaust pipes or ventilation openings as possible, that is, the above exhaust gas is used as the back-end thermal fluid, and the temperature of the rear-end thermal fluid is obviously higher than When the thermal fluid at the front end of the heat absorbing section is used, it has good absorption value for further absorption and utilization of internal energy in the thermal fluid at the rear end.

Embodiment 3

[0035] This embodiment is further limited on the basis of Embodiment 1. In order to make full use of the internal energy in the high-grade thermal fluid, the heat exchange between the high-grade thermal fluid and the heat carrier can be repeated. As a way to realize the above-mentioned solution, It also includes a bypass line 6 , the inlet end and the outlet end of the bypass line 6 are respectively located at the rear end and the front end of the evaporator 4 .

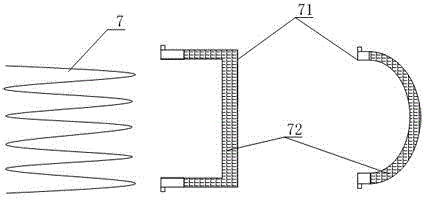

[0036] In order to make full use of the internal energy in the high-grade thermal fluid, the heat exchange between the high-grade thermal fluid and the heat carrier can be repeated. As another way to realize the above-mentioned solution, the thermal fluid inlet port of the evaporator 4 and the The thermal fluid outlet ends are adjacent. In this way, the overall structure of the evaporator 4 can be set in a bent shape, such as a U shape, that is, without changing the total length of the heat exchange flow channel of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com