A skid-mounted automatic liquid discharge device for venting and separating liquid

An automatic liquid drainage and skid-mounted technology, which is applied in the direction of gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as heavy workload, increased workload, pipeline slug flow, etc., and improve work efficiency , Reduce labor intensity and prevent slug flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

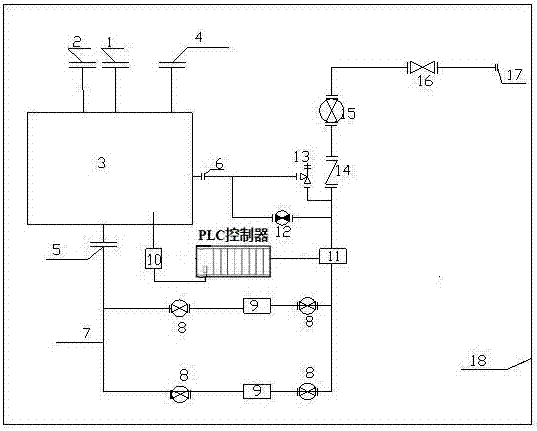

[0021] This embodiment provides a skid-mounted automatic liquid discharge device for emptying and liquid separation, including a gas-liquid separator 3, a skid seat 18 is provided below the gas-liquid separator 3, and a bottom of the gas-liquid separator 3 The sewage outlet 5 is connected with the reciprocating pump 11 located on the skid base 18 through the sewage pipeline 7, and the gas-liquid separator 3 is provided with a liquid level monitor 10, and the liquid level monitor 10 is connected with the skid base 18. The input end of the PLC controller is connected, and the reciprocating pump 11 is connected with the output end of the PLC controller.

[0022] Working process: When the gas gathering station is put into operation, the incoming gas from the vent pipeline enters the gas-liquid separator 3 through the incoming gas interface 1, the incoming liquid from the sewage pipe enters the gas-liquid separator 3 through the incoming liquid interface 2, and the incoming gas from...

Embodiment 2

[0026] On the basis of Embodiment 1, a first ball valve 8 and a filter 9 are sequentially provided between the sewage pipeline 7 and the reciprocating pump 11. In this embodiment, after the sewage comes out through the sewage outlet 5, it enters the sewage pipeline 7 and passes through the first ball valve. 8 and a filter 9, wherein the filter 9 filters solid particles and impurities in the liquid, and then enters the reciprocating pump 11 for pressurization.

Embodiment 3

[0028] On the basis of Embodiment 1, a check valve 14 is provided on the outlet pipeline of the reciprocating pump 11; the middle and lower part of the gas-liquid separator 3 is provided with a liquid return port 6, and the liquid return port 6 is connected to the reciprocating pump 11 through the first pipeline. A safety valve 13 is provided on the first pipeline, and a second pipeline is provided between the liquid return port 6 and the outlet pipeline of the reciprocating pump 11, and a second ball valve 12 is provided on the second pipeline.

[0029] When the reciprocating pump 11 is turned on for the first time, the check valve 14 is closed and the second ball valve 12 is opened. After the sewage comes out through the sewage outlet 5, it enters the sewage pipeline 7, and then enters the reciprocating pump 11 for pressurization. After pressurization, the sewage passes through the second ball valve 12, and the liquid return port 6 enters the gas-liquid separator 3 for separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com