Electrical heat energy-mechanical energy comprehensive rock breaking drill

A mechanical energy and rock-breaking technology, which is applied in the application of thermal energy drilling, drill bits, drilling equipment, etc., can solve the problems of slow drilling speed, low energy conversion rate, and low safety factor in hard formations, so as to increase the mechanical drilling speed and reduce the drilling speed. cost, and the effect of improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings.

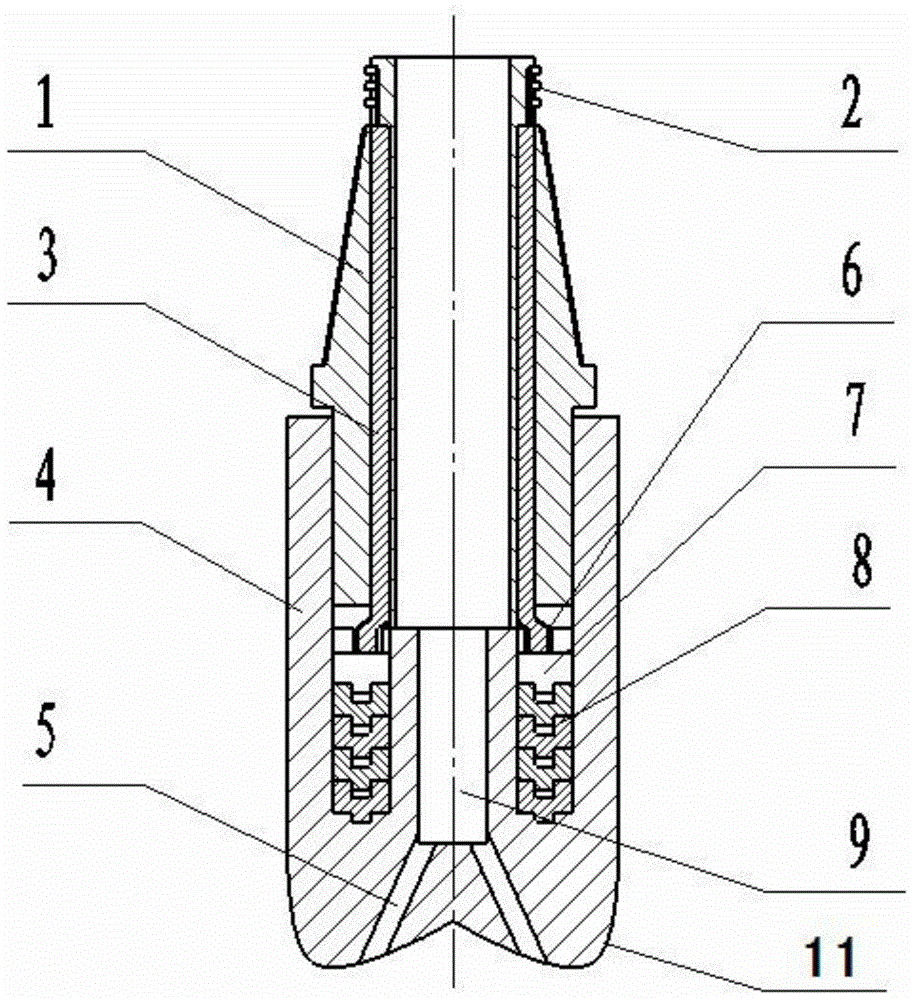

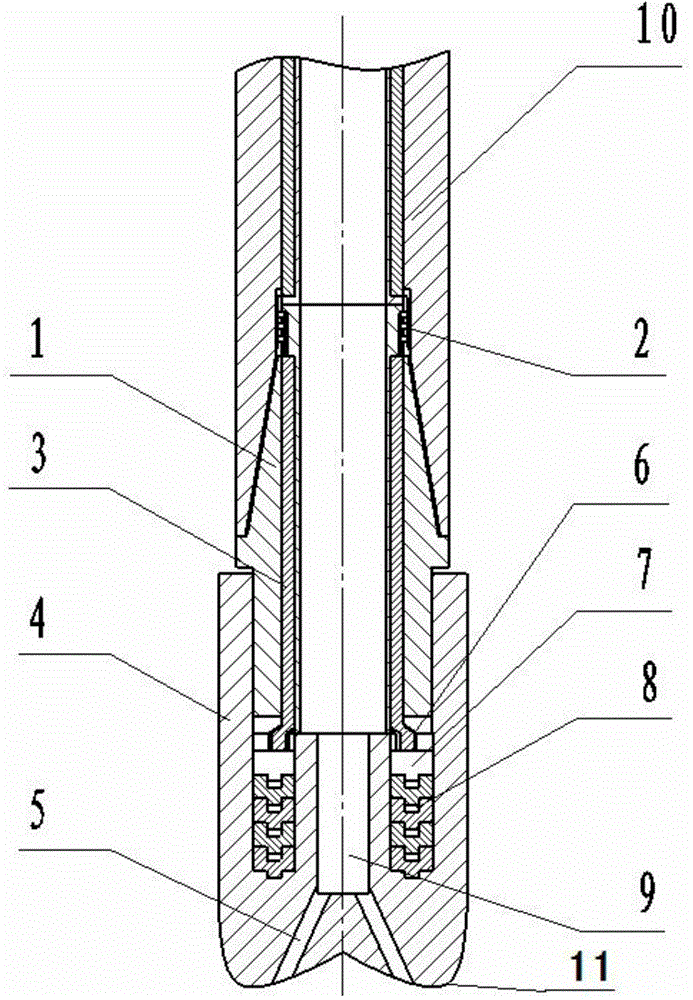

[0022] Such as figure 1 As shown, a kind of electrothermal-mechanical energy comprehensive rock-breaking drill bit includes a threaded joint 1, a cable 3, a casing 4, a heat exchange tube 9, an electric heating device 7 and a heat conduction element; the lower end of the threaded joint 1 is connected to the casing 4 through threads ( The shell 4 is set on the threaded joint 1), the threaded joint 1 is provided with a central hole, the shell 4 is provided with an annular groove, a heat exchange tube 9 and a nozzle 5, the material of the heat exchange tube 9 is copper or aluminum, and the center hole , the heat exchange tube 9, and the nozzle 5 are connected in sequence, the outlet of the nozzle 5 is set on the bottom surface of the shell 4 (the bottom surface of the shell 4 is concave in the middle, and the surrounding is convex, which is conducive to rapid drilling), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com