Modified melamine water reducer and preparation method thereof

A technology of melamine and water reducing agent, applied in the field of concrete admixtures, can solve problems such as environmental pollution and large slump loss, and achieve the effects of improving water reducing effect, improving repulsion effect, and increasing steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

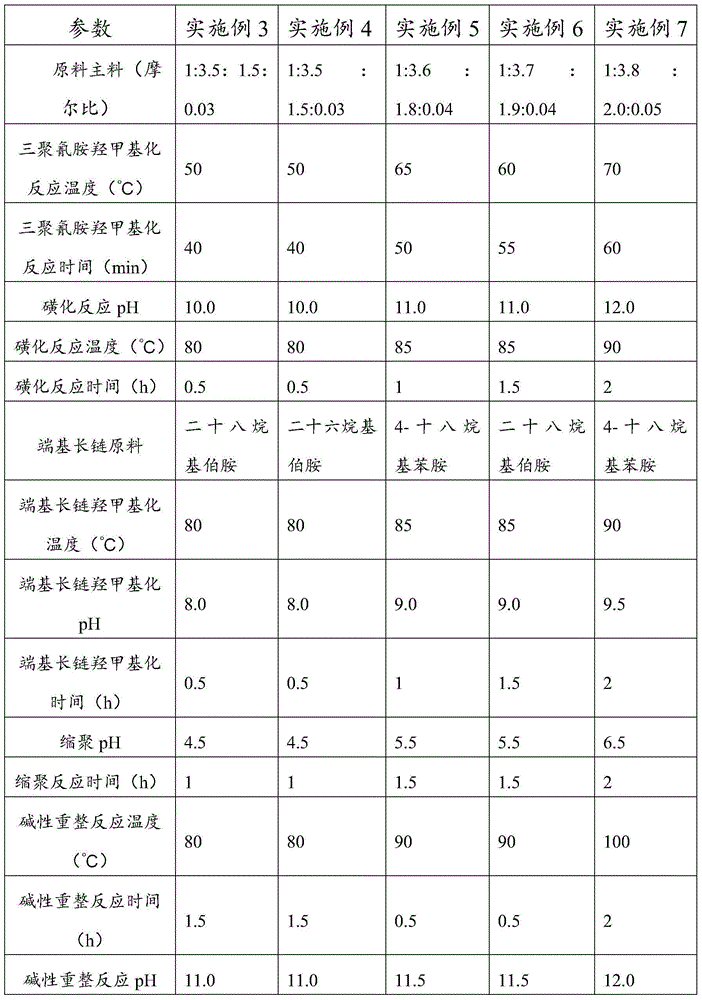

Examples

Embodiment 1

[0026] A modified melamine water-reducer, which introduces organic long chains at the molecular ends of the melamine water-reducer, and the molar ratio of raw materials when synthesizing organic long chains is: long-chain raw materials: formaldehyde = 1:1; the raw material molar ratio of the present invention For: melamine: formaldehyde: sodium bisulfite: end group long chain = 1:3.5:1.5:0.03.

[0027] The long-chain raw material is octadecyl primary amine.

[0028] The formaldehyde is 37% formaldehyde aqueous solution.

[0029] Described sulfuric acid is 10% sulfuric acid solution.

[0030] The preparation method of above-mentioned modified melamine water reducing agent comprises the following steps:

[0031] S1. Add formaldehyde solution and long-chain raw materials in sequence, adjust the pH value of the solution to 8.0, keep the temperature of 80-90°C and continue the reaction for 0.5-2 hours, and carry out the methylolation reaction of long-chain raw materials;

[0032...

Embodiment 2

[0038] A modified melamine water-reducer, which introduces organic long chains at the molecular ends of the melamine water-reducer, and the molar ratio of raw materials when synthesizing organic long chains is: long-chain raw materials: formaldehyde = 1:1; the raw material molar ratio of the present invention For: melamine: formaldehyde: sodium bisulfite: end group long chain = 1:3.8:2.0:0.05.

[0039] The long-chain raw material is 4-octadecylaniline.

[0040] The formaldehyde is 37% formaldehyde aqueous solution.

[0041] Described sulfuric acid is 10% sulfuric acid solution.

[0042] The preparation method of above-mentioned modified melamine water reducing agent comprises the following steps:

[0043] S1. Add formaldehyde solution and long-chain raw materials in sequence, adjust the pH value of the solution to 9.5, keep the temperature at 90°C and continue the reaction for 0.5 hours, and carry out the methylolation reaction of long-chain raw materials;

[0044] S2. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com