Water treatment method for removing pollution through singlet oxygen dissolved air flotation

A technology of dissolved air flotation and singlet oxygen, which is applied in the field of water treatment, can solve problems such as difficult to remove organic pollutants, and achieve the effects of simple operation, convenient transportation and storage, and high pollution removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

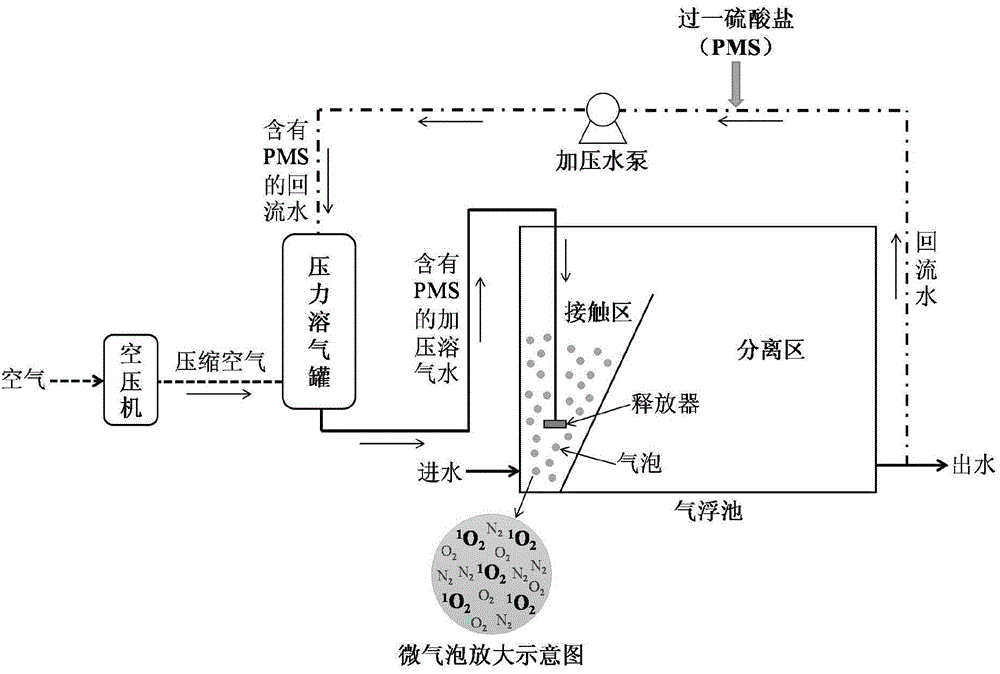

[0016] Specific implementation mode 1: This implementation mode is a water treatment method using singlet oxygen dissolved air flotation to remove pollution, which is realized through the following steps:

[0017] 1. Add the persulfate solution into the reflux water of the dissolved air flotation process, pump it into the pressure dissolved air tank through a pressurized water pump, and inject compressed air into the pressure dissolved air tank through an air compressor to form a Pressure-dissolved gas water; wherein, the concentration of the persulfate solution in the reflux water is 0.5-500mg / L;

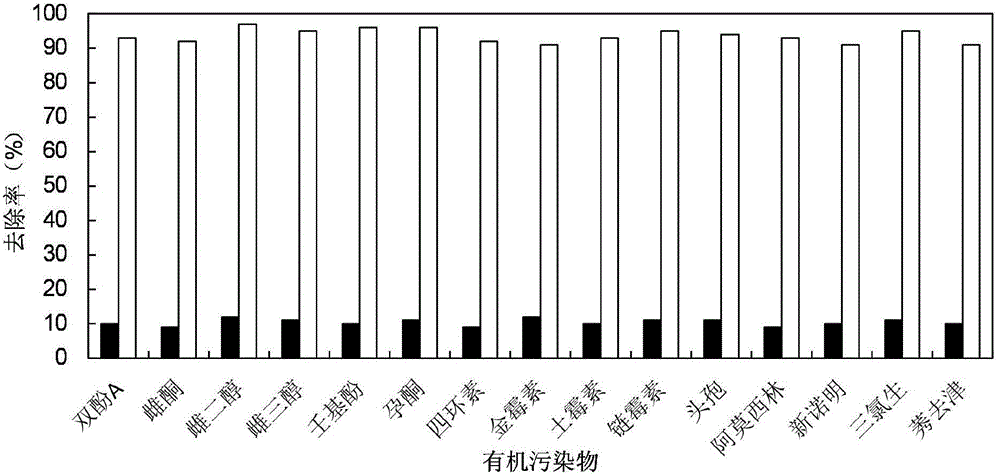

[0018] 2. Release the pressurized dissolved air water in step 1 through the release device to generate 1 o 2 ) enters the water to be treated for oxidation and separation; after draining and slag discharge, the water treatment using singlet oxygen dissolved air flotation to remove pollution is completed; wherein, the water to be treated is source water , sewage or sewage plant se...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the persulfate is sodium persulfate (NaHSO 5 ), potassium persulfate (KHSO 5 ), ammonium persulfate (NH 4 HSO 5 ), calcium persulfate (Ca(HSO 5 ) 2 ), magnesium persulfate (Mg(HSO 5 ) 2 ) in one or several mixtures in any ratio. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 2 in that the concentration of peroxymonosulfate in the reflux water is 1-450 mg / L. Other steps and parameters are the same as one of the specific implementation modes 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com