Tunnel field effect transistor and manufacturing method thereof

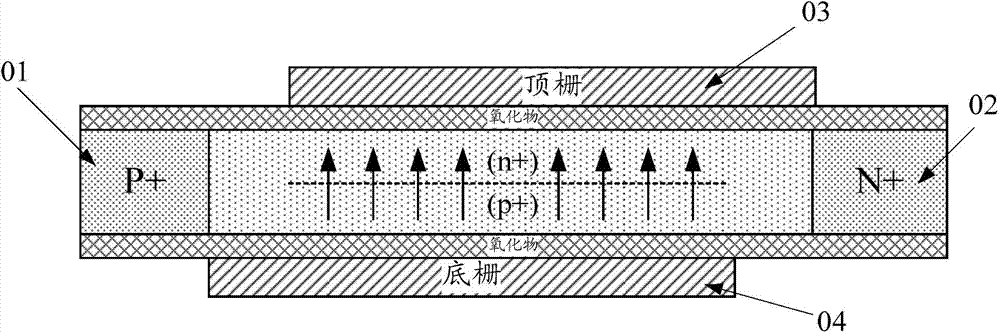

A tunneling field effect, transistor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low versatility of EHB-TFET

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

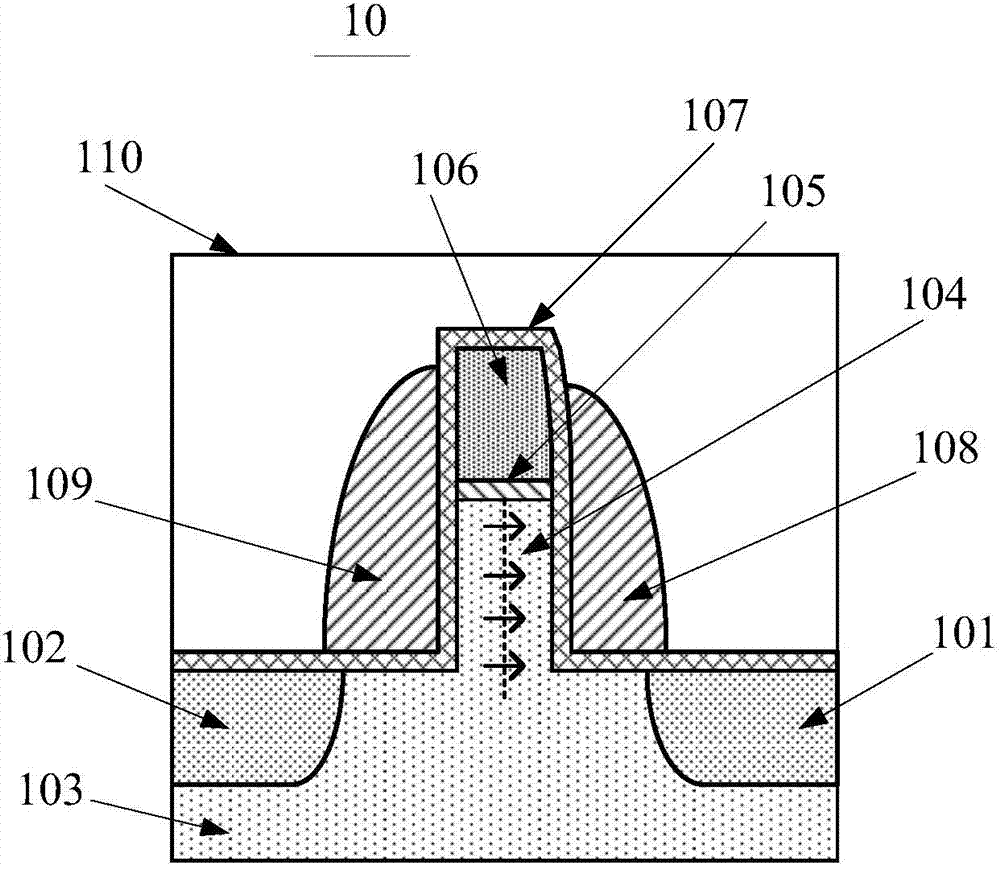

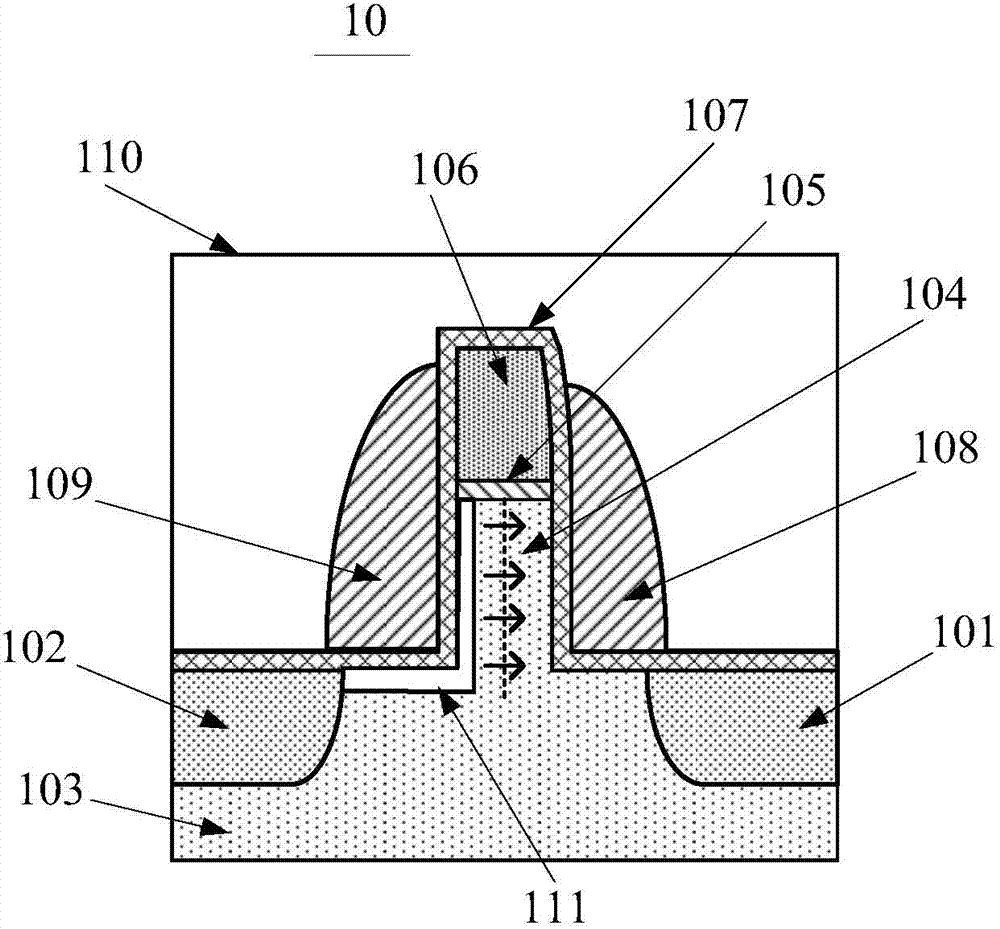

[0108] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0109] An embodiment of the present invention provides a tunneling field effect transistor 10, the structural diagram of the tunneling field effect transistor 10 is as follows figure 2As shown, it includes: a substrate 103 with a first doped region 101 and a second doped region 102 respectively disposed at both ends; a channel region 104 with fin-shaped protrusions formed on the substrate 103; A protective layer 105 is formed on the substrate 103 of 104; a trench etching hard mask layer structure 106 in the shape of a sidewall is formed on the substrate 103 formed with the protective layer 105; a trench etching hard mask layer structure 106 in the shape of a sidewall is formed; A gate insulating dielectric layer 107 is formed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com