A high-energy-saving and environment-friendly liquid burner

An energy saving, environmental protection, burner technology, applied in liquid fuel burners, burners, burners, etc., can solve problems such as flame instability, and achieve the effect of uniform and stable wind force, convenient fixation, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

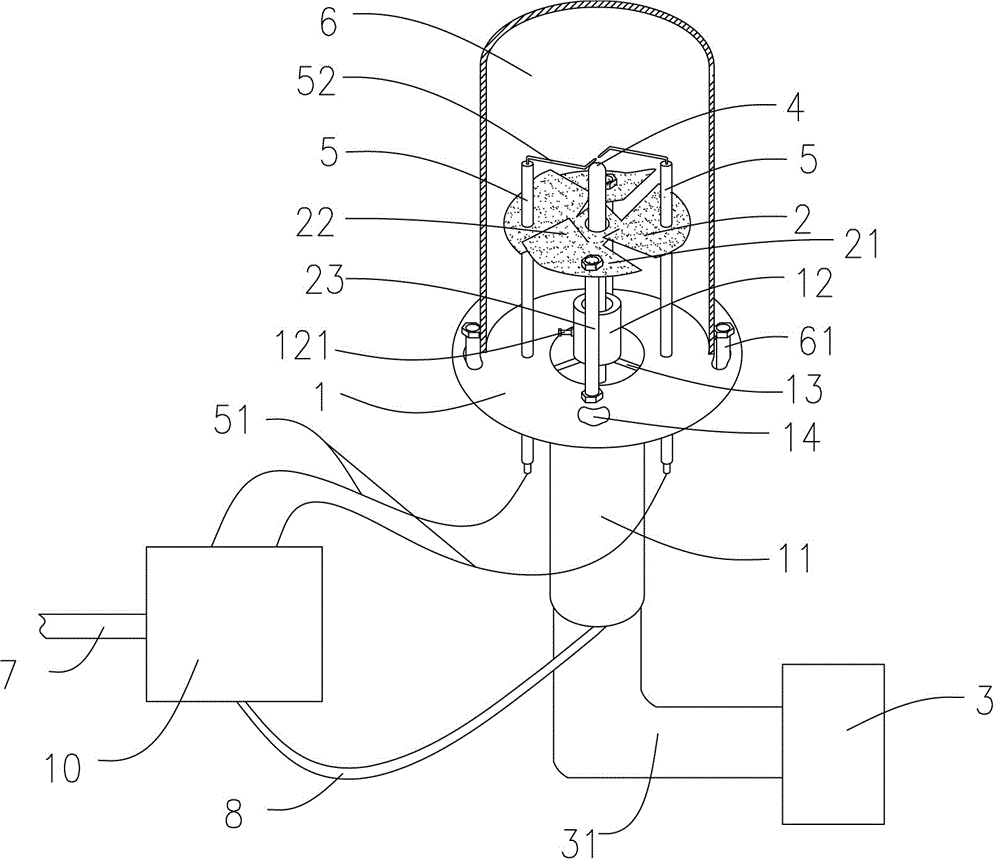

[0019] Such as figure 1 As shown, a high-energy-saving and environment-friendly liquid burner according to an embodiment of the present invention includes an ignition part and a control pressurization part. The ignition part includes an ignition needle 5 and a fuel injection nozzle 4. There are two ignition needles 5. There is an ignition needle 52, and the two needles are arranged opposite to each other. The lower end of the ignition needle 5 is connected to the control pressurization part 10 through the high-voltage ignition wire 51, and the upper end of the fuel injection nozzle 4 is located below the ignition needle 5. The pressure part 10 is connected to the lower end of the fuel injection nozzle 4 through the fuel outlet pipe 8. After the needle of the ignition needle is ignited by a high-voltage pulse, the liquid fuel is ejected from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com