Tile surface material composite plate and novel construction method thereof

A construction method and technology of composite boards, applied in the processing of building materials, covering/lining, construction, etc., can solve the problems of inability to lay tiles at a high and precise level, and meet the stringent requirements for lowering the level of installation technology and bactericidal performance Excellent results from a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A novel construction method for a ceramic tile surface material composite board, comprising the following steps:

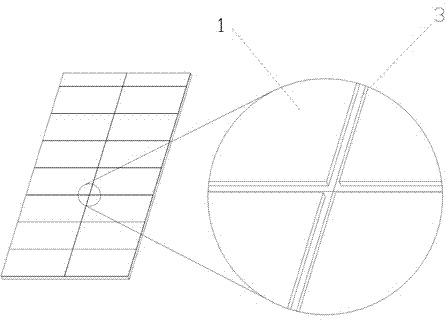

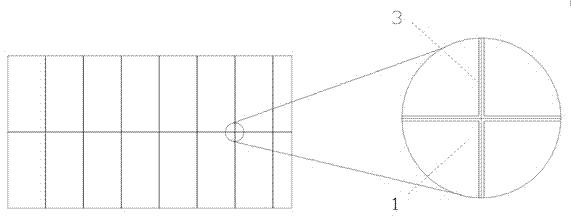

[0050] (1) Arrange a number of tile surface materials and paste them on a substrate so that the tile surface materials are tightly connected to each other without gaps or small gaps, and align the connection seams to form a tile surface material splicing board ;

[0051] (2) Clean the splicing panels of tile surface materials so that there are no debris in the connection gaps;

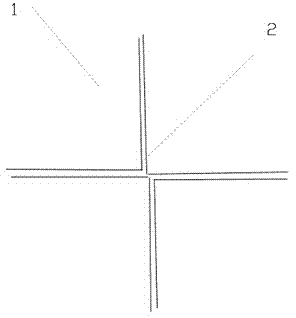

[0052] (3) On the vertically and horizontally aligned connecting sutures of the tile surface material splicing boards, set up linear grooving in batches through diamond grinding wheels, so that the width of the grooving can completely cover the connection gap between the tile surface materials, and then clean the grooving generated Dust, particles; the maximum width of the connection gap is 0.5mm, and the width of the cut groove is 2mm, which can cover all the connection seams betw...

Embodiment 2

[0057] A novel construction method of a ceramic tile surface material composite board, which is basically the same as that of Embodiment 1, the difference is that:

[0058] Step (3): Use a chemical etchant to cut the groove. The maximum width of the connection gap is 3mm, and the width of the cut groove is 5mm, which can cover all the connection seams between the tile surface material composite boards. The depth is 10mm, which can be allowed to cure caulking agent.

[0059] The cut grooves are all set on the outer side of the splicing gap of the ceramic tile surface materials. The ceramic tile surface material is a natural stone plate, and the base plate is a honeycomb plate.

[0060] The beauty joint agent is made by mixing the following raw materials in parts by weight: 20 parts of white cement, 15 parts of steel slag powder, 10 parts of porcelain powder, 16 parts of vitrified microspheres, 5 parts of kaolin, 16 parts of barium sulfate, fumed silica 2 parts, 5 parts of cal...

Embodiment 3

[0062] A novel construction method of a ceramic tile surface material composite board, which is basically the same as that of Embodiment 1, the difference is that:

[0063] The beautifying agent is made by mixing the following raw materials in parts by weight: 30 parts of white cement, 8 parts of steel slag powder, 20 parts of porcelain powder, 12 parts of vitrified microspheres, 10 parts of kaolin, 10 parts of barium sulfate, fumed silica 3 parts, 3 parts of calcium formate, 3 parts of graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com