Corrosion and wear resistant insulating varnish and preparation method thereof

A wear-resistant and insulating paint technology, used in anti-corrosion coatings, coatings, etc., can solve problems such as single performance, and achieve the effect of high insulation performance, good performance and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

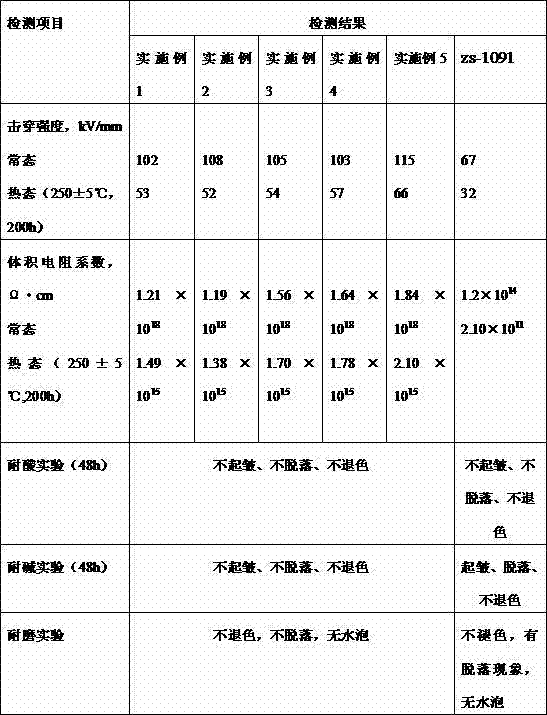

Examples

preparation example Construction

[0028] The present invention also includes a preparation method of corrosion-resistant and wear-resistant insulating varnish, comprising the following steps:

[0029] ① Add formaldehyde to xylene, add mixed acid to it dropwise, control the temperature during dropping at 30~40°C, reflux for 5~7 hours after dropping, let stand to obtain a mixed solution, and separate the mixed solution after standing , the upper layer is a xylene formaldehyde resin, and the lower floor is water, remove the water in the lower layer to obtain a xylene formaldehyde resin; the mass ratio of the formaldehyde, xylene and mixed acid is 1~2:3~4:1; the mixed acid It is obtained by mixing sulfuric acid and acetic acid in a molar ratio of 1:1;

[0030] ② Add phenol to the xylene formaldehyde resin obtained in step ①, raise the temperature to 80-90°C and keep it for 1-2 hours to obtain a reaction solution, cool the reaction solution to 20-30°C, add sodium hydroxide to adjust the pH of the reaction solution ...

Embodiment 1

[0044] A corrosion-resistant and wear-resistant insulating paint, which consists of the following components in parts by weight: 20 parts of xylene modified phenolic resin, 30 parts of lauric acid modified alkyd resin, 25 parts of phenyltrimethylsilane, o-benzene 5 parts of dicarboxylate, 2 parts of kaolin, 4 parts of mica powder, 5 parts of illite powder, 30 parts of isophorone diisocyanate, 1 part of dibutyltin dilaurate, 4 parts of dioctyl terephthalate, coconut oil 1 part of amidopropyl betaine and 10 parts of tert-butyl methacrylate.

[0045] The preparation method comprises the following steps:

[0046] ① Add formaldehyde to xylene, add mixed acid to it dropwise, control the dropwise temperature at 30°C, reflux for 5 hours after the dropwise addition, and let it stand still to obtain a mixed solution. Toluene formaldehyde resin, the lower layer is water, remove the water in the lower layer to obtain xylene formaldehyde resin; the mass ratio of formaldehyde, xylene and m...

Embodiment 2

[0053] A corrosion-resistant and wear-resistant insulating paint, which consists of the following components in parts by weight: 30 parts of xylene modified phenolic resin, 40 parts of lauric acid modified alkyd resin, 40 parts of phenyltrimethylsilane, o-benzene 20 parts of dicarboxylate, 5 parts of kaolin, 10 parts of mica powder, 8 parts of illite powder, 40 parts of isophorone diisocyanate, 3 parts of dibutyltin dilaurate, 8 parts of dioctyl terephthalate, coconut oil 3 parts of amidopropyl betaine and 15 parts of tert-butyl methacrylate.

[0054] The preparation method comprises the following steps:

[0055] ① Add formaldehyde to xylene, add mixed acid to it dropwise, control the temperature during dropping at 40°C, reflux for 7 hours after dropping, and let stand to obtain a mixed solution. Toluene formaldehyde resin, the lower layer is water, remove the water in the lower layer to obtain xylene formaldehyde resin; the mass ratio of the formaldehyde, xylene and mixed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com