Flotation separation process for mixed copper and lead concentrate

A technology for mixing concentrate and copper and lead, applied in the field of metallurgy, can solve the problems of difficult separation, poor adaptability, etc., and achieve the effect of ensuring the effect of drug removal, cheap drugs, and low mutual content of copper and lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

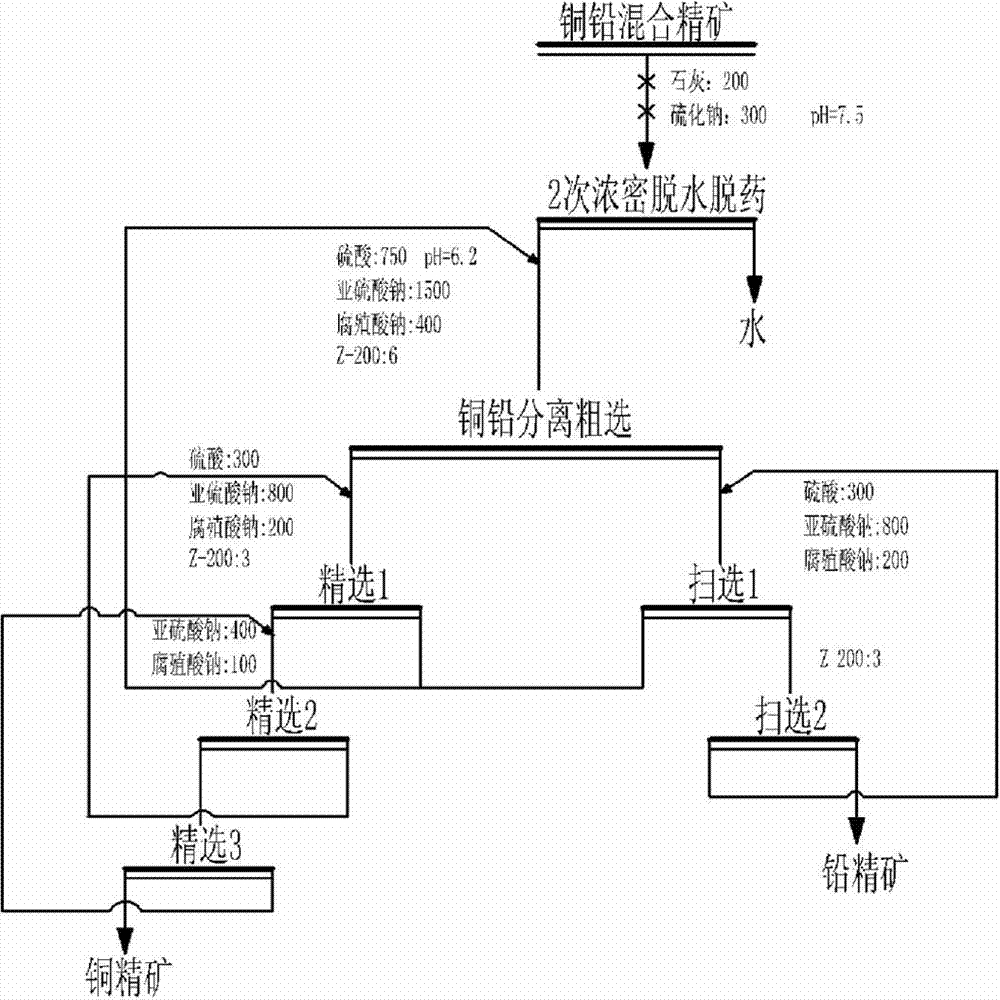

[0031] The flotation separation of copper-lead mixed concentrate was carried out on a copper-lead-zinc polymetallic mine in Yunnan. The chemical multi-element analysis results of the ore are shown in Table 1, and the separation results are shown in Table 2. figure 2 , the specific flotation separation operation is as follows: (1) Add 200g / t lime and 300g / t sodium sulfide to the copper-lead mixed concentrate and stir for 2 minutes, and the pH is about 7.5. (2) The stirred pulp is dehydrated twice , after each thickening, use fresh water to adjust the pulp, (3) add 750g / t sulfuric acid to adjust the pH value of the thickened dehydrated pulp, the pH is controlled at about 6.2, and then add 1500g / t sodium sulfite and 400g / t sodium humate As a combined inhibitor of lead minerals, 6g / t Z-200 was added as a collector for copper-lead separation. (4) The flotation separation process is one rough, three fine and two sweeps, and finally copper concentrate and lead concentrate are obtain...

Embodiment 2

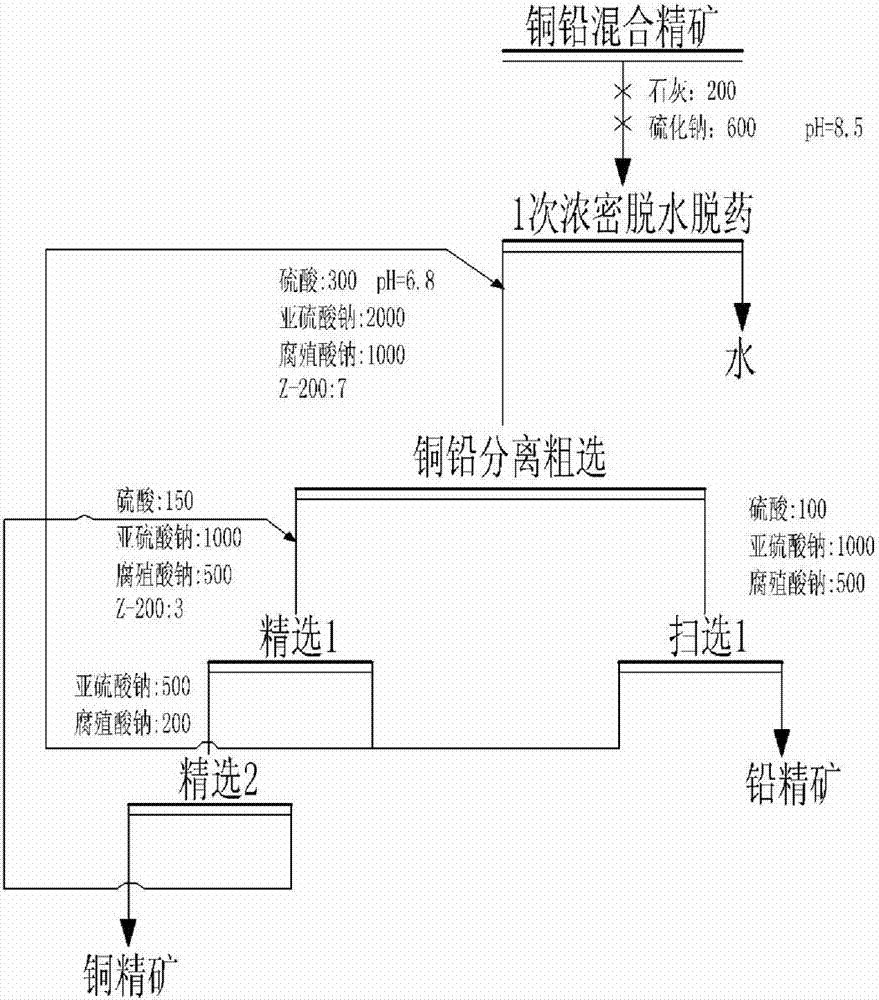

[0039] A copper-lead-zinc polymetallic ore in Northeast China was subjected to flotation separation of copper-lead mixed concentrate. The chemical multi-element analysis results of the ore are shown in Table 3, and the separation results are shown in Table 4. The copper-lead flotation separation process is shown in the appendix image 3 , the specific flotation separation operation is as follows: (1) add 200g / t lime and 600g / t sodium sulfide to the copper-lead mixed concentrate and stir for 2 minutes, and the pH is about 8.5; (2) the stirred pulp undergoes a dense dehydration, After thickening, use fresh water to adjust the pulp. (3) Add 300g / t sulfuric acid to the pulp after thickening and dehydration to adjust the pH value. Combined inhibitor of lead minerals, adding 7g / t Z-200 as collector for copper and lead separation. (4) The flotation separation process is one rough, two fine and one sweep, and finally copper concentrate and lead concentrate are obtained. See the attach...

Embodiment 3

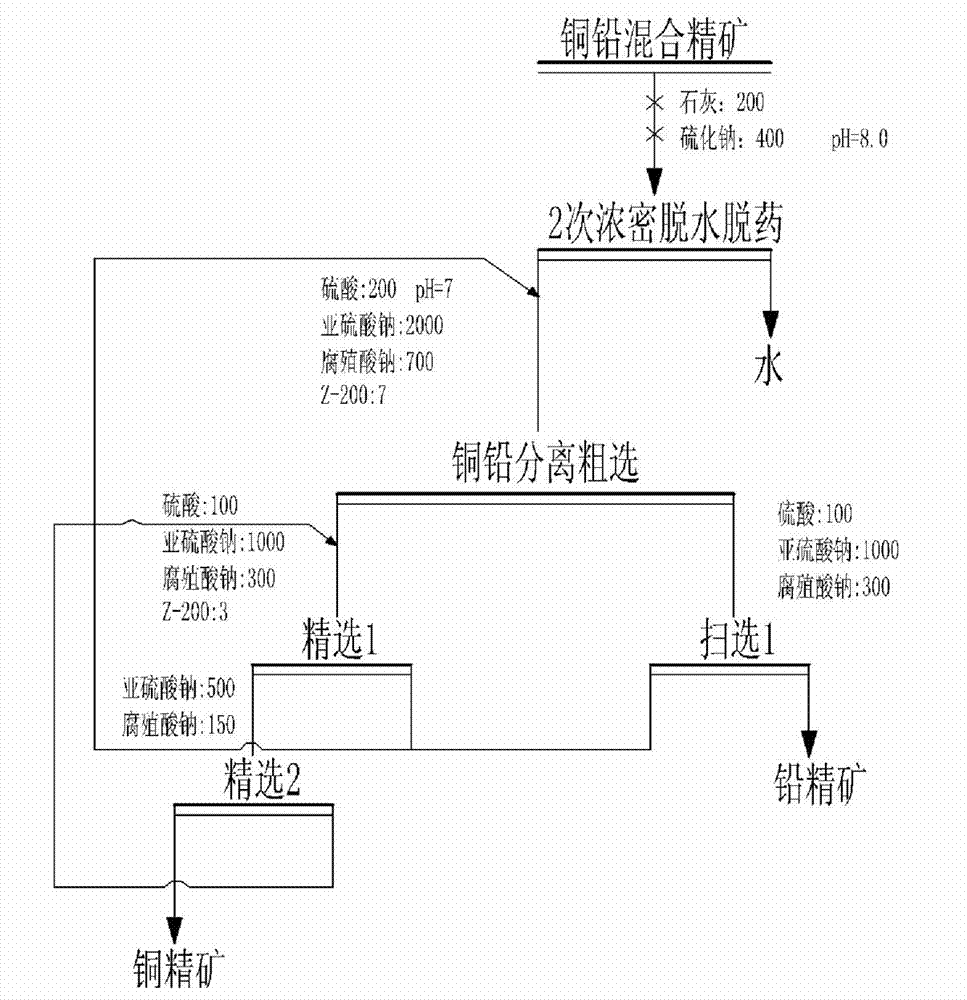

[0045] The flotation separation of copper-lead mixed concentrate was carried out on a copper-lead-zinc polymetallic mine in Yunnan. The chemical multi-element analysis results of the ore are shown in Table 5, and the separation results are shown in Table 6. The copper-lead flotation separation process is shown in the appendix Figure 4 , the specific flotation separation operation is as follows: (1) Add 200g / t lime and 400g / t sodium sulfide to the copper-lead mixed concentrate and stir for 3 minutes, and the pH is about 8.0. (2) The stirred pulp is dehydrated twice , after each thickening, use fresh water to adjust the pulp. (3) Add 200g / t sulfuric acid to adjust the pH value of the thickened dehydrated pulp. The pH is controlled at about 7.0, and then add 2000g / t sodium sulfite and 700g / t sodium humate As a combined inhibitor of lead minerals, 7g / t Z-200 was added as a collector for copper and lead separation. (4) The flotation separation process is one rough, two fine and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com