Method for producing vinyl ester urethane resins based on dianhydrohexitol compounds and use thereof

A technology of dianhydrohexitol and polyurethane resin, which is applied in the field of vinyl ester polyurethane resin and can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

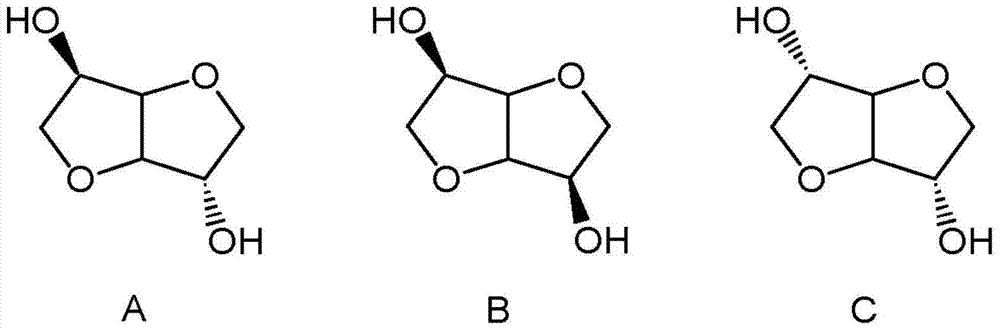

Image

Examples

Embodiment

[0049] A) Synthesis of resin masterbatch

[0050] A1) Application of Tetramethylene Diisocyanate (TMDI)

Embodiment A11

[0052] In a 500 mL three-necked flask, 260 g of 1,3-propanediol dimethacrylate (Sarbio6200) and 50 g of TMDI were placed in advance and mixed with 30 mg of dioctyltin dilaurate (Tegokat216), 20 mg of BHT and 40 mg of Tempol. The solution was tempered at 70°C. 20 g of isosorbide were then added to the stirred solution in 20 equal portions over 60 minutes. After the addition of isosorbide was complete, the mixture was heated to 80° C. and stirred at this temperature for 5 hours. The reaction of isosorbide was controlled by thin layer chromatography. After 5 hours, the isosorbide was completely reacted. Subsequently, 50 g of HPMA were added dropwise over 60 minutes and further stirred at 80° C. until the NCO content determined according to DIN EN 1242 was less than 0.2%. This gives a ready-to-use resin masterbatch.

Embodiment A12

[0054] 250 g of 1,4-butanediol dimethacrylate and 40 g of TMDI were pre-charged into a 500 mL three-necked flask, and mixed with 60 mg of dioctyltin dilaurate (Tegokat216), 40 mg of BHT and 90 mg of Tempol. The temperature of the solution was adjusted at 70°C. 20 g of isosorbide were then added to the stirred solution in 20 equal portions over 60 minutes. After the addition of isosorbide was complete, the mixture was heated to 80° C. and stirred at this temperature for 5 hours. The reaction of isosorbide was controlled by thin layer chromatography. After 5 hours, the isosorbide was completely reacted. Subsequently, 40 g of HPMA were added dropwise over 60 minutes and further stirred at 80° C. until the NCO content determined according to DIN EN 1242 was less than 0.2%. This gives a ready-to-use resin masterbatch.

[0055] A2) Application of hexamethylene diisocyanate (HMDI)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com