Evaluation method for ageing state of composite insulator

A composite insulator, aging state technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of high experimental conditions, difficult to obtain, different physical and chemical properties, etc., to achieve simple and convenient operation and eliminate human factors. , the effect of simplifying the operation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

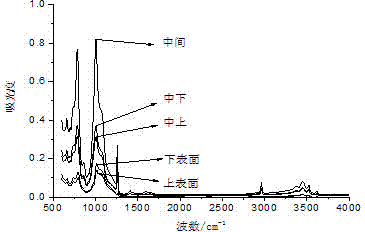

[0036] Select a composite insulator running on a high-voltage line, take an insulator shed on the low-voltage side of the insulator, and select a cylindrical sample at the position with the smallest surface aging degree on the shed. The diameter of the sample is 20 mm, and use a slicing device to The sample is cut into a test piece with a thickness of 1 mm, and the test pieces at five positions of the upper surface, the upper middle, the middle, the lower middle and the lower surface are sequentially obtained. At the same time, take the new product of the composite insulator mentioned above as a control sample, and cut a test piece. Using Fourier transform infrared spectrometer to carry out aging test on samples with different depths of sheds, the results are as follows figure 2 and shown in Table 1.

[0037] Table 1. Wavenumbers of FTIR spectra of test pieces with different depths of the shed

[0038] Location C-H Si-CH3 Si-O-Si Si-(CH3)2 upper surfa...

Embodiment 2

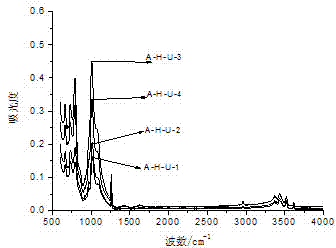

[0041] The composite insulator A of a manufacturer operating on the 220 kV line in the coastal area of Hebei Province for about 10 years was selected as the research object.

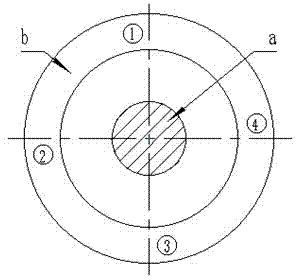

[0042] Step a: Take the test piece: Take the high-voltage side and medium-voltage side sheds of the composite insulator A, divide the sheds into four right-angle fan-shaped areas with the mandrel as the center, and cut a 20mm-diameter section in each area with a sampling device. Cylindrical samples. And use a slicing device to cut the sample into several test pieces with a thickness of 1 mm along the axial direction. Take the upper surface test piece of each sample as the test piece to be tested.

[0043] A set of equipment suitable for sample preparation of on-site composite insulator sheds is used for sampling. The equipment is the sampler and slicing mechanism introduced in the patent 201310341441.3 titled A Method for Testing the Aging Degree of Silicone Rubber Composite Insulators. The sampler ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com