A Fixing Mechanism for Remote Pressure Transmitter

A fixed mechanism and transmitter technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of affecting the pressure bearing capacity of the flange, weak anti-vibration ability, thinning of asbestos insulation layer, etc., to reduce procurement Lower cost, improved safety and reliability, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

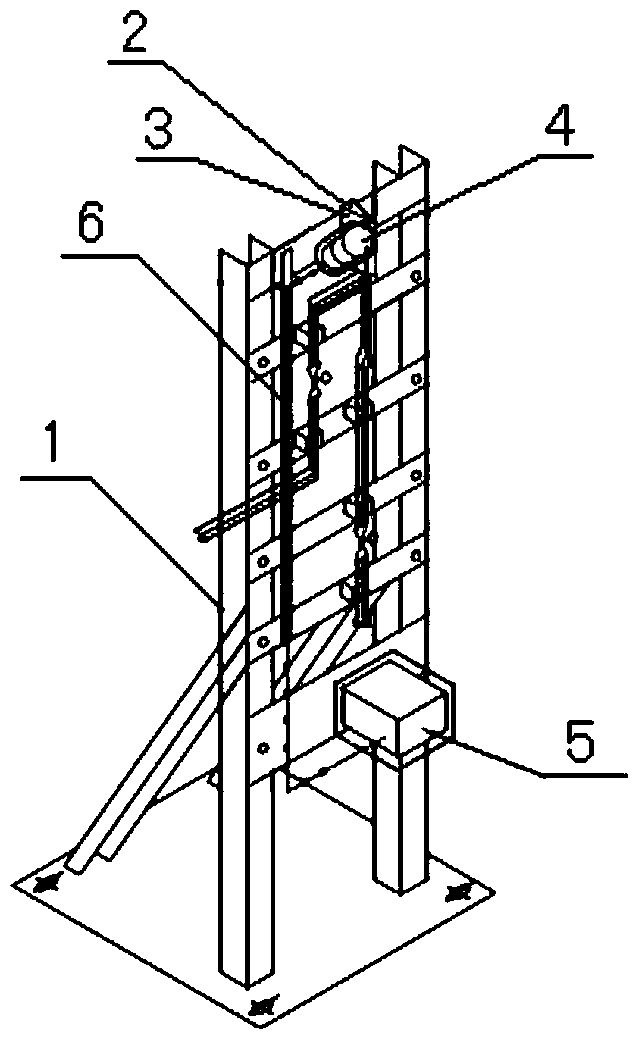

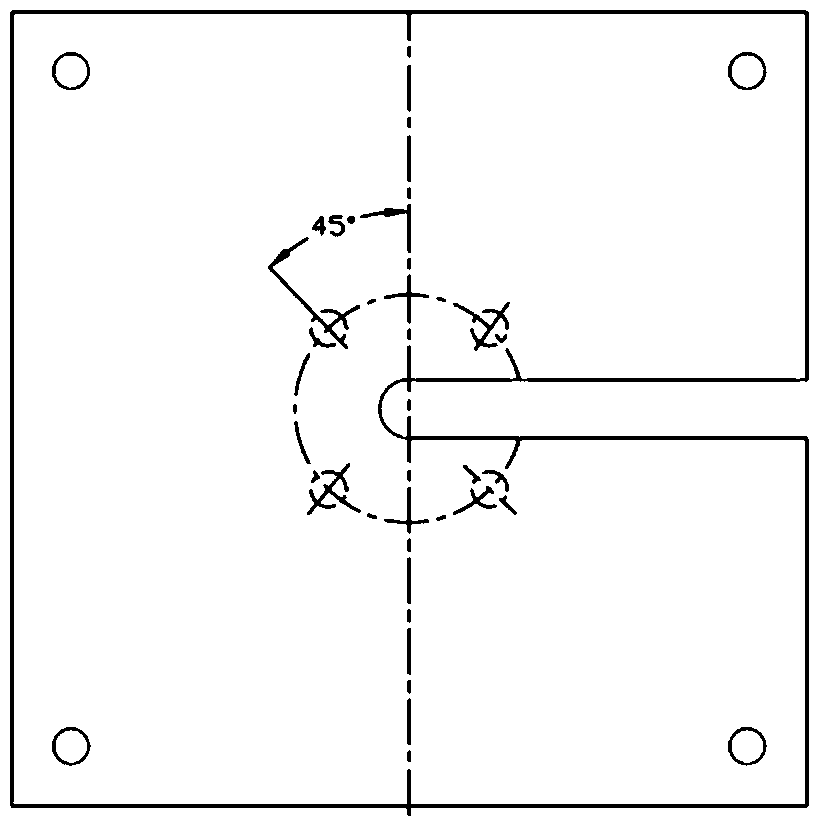

[0016] Such as figure 1 As shown, the present invention provides a fixing mechanism for a remote pressure transmitter, wherein the remote pressure transmitter includes a remote seal assembly 4 arranged at the measuring end of the transmitter, and the remote seal assembly 4 includes a flange And the pressure measuring diaphragm sealed in the end face of one side of the flange.

[0017] Such as figure 1 As shown, the fixing mechanism of the remote pressure transmitter provided by the present invention includes an instrument frame 1 for carrying the remote seal assembly 4, the instrument frame 1 is provided with a mounting plate 2, and a bakelite board 3 is connected to the mounting plate 2 , the flange of the remote sealing assembly 4 is connected to the bakelite 3 . Bakelite board 3 plays heat insulation and installs and fixes effect.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com