A method for increasing the molten iron ratio of converter and reducing smelting cost

A technology of molten iron ratio and converter, which is applied in the field of metallurgy, and can solve the problems of high price of purchased scrap steel and large fluctuations in the quality of scrap steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

[0029] A process for reducing smelting costs by increasing the ratio of molten iron in the converter. By increasing the charging ratio of molten iron in the converter, the operation of slag retention and less slag can be realized by using the excess heat. At the same time, the excess heat is used to reduce the cost of converter steel material, slag material, and medium cost, and realize the purpose of negative energy steelmaking, energy saving and emission reduction.

[0030] In this embodiment, 14207054 heats and steel grade S355J-2 of a steel company are selected, and the entire converter smelting process is controlled as follows:

[0031] (1) Steel type converter target composition (%)

[0032]

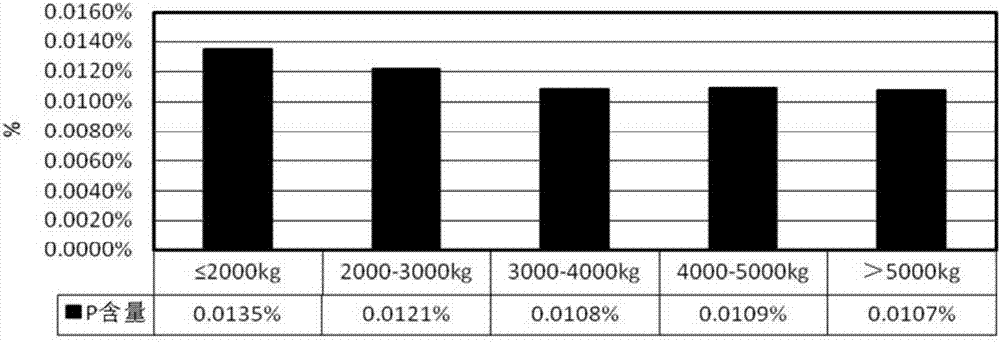

[0033] (2) The charging system of the metal material into the converter and the composition of the molten iron

[0034] Due to the need to increase the molten iron ratio, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com