Method for removing asphalt from oil residues under reduced pressure

A technology of vacuum oil and oil bitumen, which is applied in the field of vacuum oil residue removal of bitumen, which can solve the problems of high energy consumption, high pressure and temperature, equipment investment and high energy consumption, and achieve low energy consumption, improved quality and recycling The effect of high efficiency and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

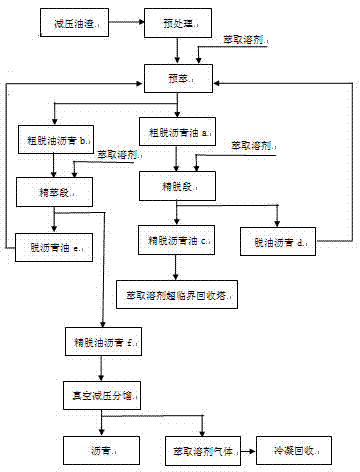

Image

Examples

Embodiment 1

[0017] A method for removing bitumen from vacuum oil residue, comprising the following steps:

[0018] (1) Pretreatment of vacuum oil residue: preliminarily heat the vacuum oil residue to a temperature of 100°C;

[0019] (2) Supercritical countercurrent extraction: The extraction solvent and the pretreated vacuum oil residue are contacted in countercurrent in the pre-extraction section in the middle of the extraction tower. The volume ratio of the extraction solvent to the pretreated vacuum oil residue is 8:1, and the extraction The temperature is 70°C, the mixing time is 4 hours, and the extraction pressure is 4.2Mpa. The upper crude deasphalted oil a and the lower crude deoiled asphalt b are obtained. The upper crude deasphalted oil a enters the upper part of the extraction tower together with the extraction solvent. In the refined deasphalting section, the volume ratio of the extraction solvent to the crude deasphalted oil a in the refined deasphalted section is 1.5:1, the...

Embodiment 2

[0026] A method for removing bitumen from vacuum oil residue, comprising the following steps:

[0027] (1) Pretreatment of vacuum oil residue: preliminarily heat the vacuum oil residue to a temperature of 110°C;

[0028] (2) Supercritical countercurrent extraction: The extraction solvent and the pretreated vacuum oil residue are contacted countercurrently in the pre-extraction section in the middle of the extraction tower. The volume ratio of the extraction solvent to the pretreated vacuum oil residue is 9:1, and the extraction The temperature is 70°C, the mixing time is 4 hours, and the extraction pressure is 4.3Mpa. The upper crude deasphalted oil a and the lower crude deoiled asphalt b are obtained. The upper crude deasphalted oil a enters the upper part of the extraction tower together with the extraction solvent. In the refined deasphalting section, the volume ratio of the extraction solvent to the crude deasphalted oil a in the refined deasphalted section is 1.5:1, the ...

Embodiment 3

[0035] A method for removing bitumen from vacuum oil residue, comprising the following steps:

[0036] (1) Pretreatment of vacuum oil residue: preliminarily heat the vacuum oil residue to a temperature of 90°C;

[0037](2) Supercritical countercurrent extraction: The extraction solvent and the pretreated vacuum oil residue are contacted countercurrently in the pre-extraction section in the middle of the extraction tower. The volume ratio of the extraction solvent to the pretreated vacuum oil residue is 9:1, and the extraction The temperature is 60°C, the mixing time is 5 hours, and the extraction pressure is 4.3Mpa to obtain the upper crude deasphalted oil a and the lower crude deoiled asphalt b, and the upper crude deasphalted oil a enters the upper part of the extraction tower together with the extraction solvent In the refined deasphalting section, the volume ratio of the extraction solvent to the crude deasphalted oil a in the refined deasphalted section is 1.5:1, the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com