Preparation method of nitrogen-doped graphene

A nitrogen-doped graphene and nitrogen source technology is applied in the field of high-temperature pyrolysis of melamine and glucose monohydrate to prepare nitrogen-doped graphene, which can solve the problems of low nitrogen content, complicated operation process, toxic precursors, etc. The route is clean and environmentally friendly, the preparation process is simple, and the raw materials are simple and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

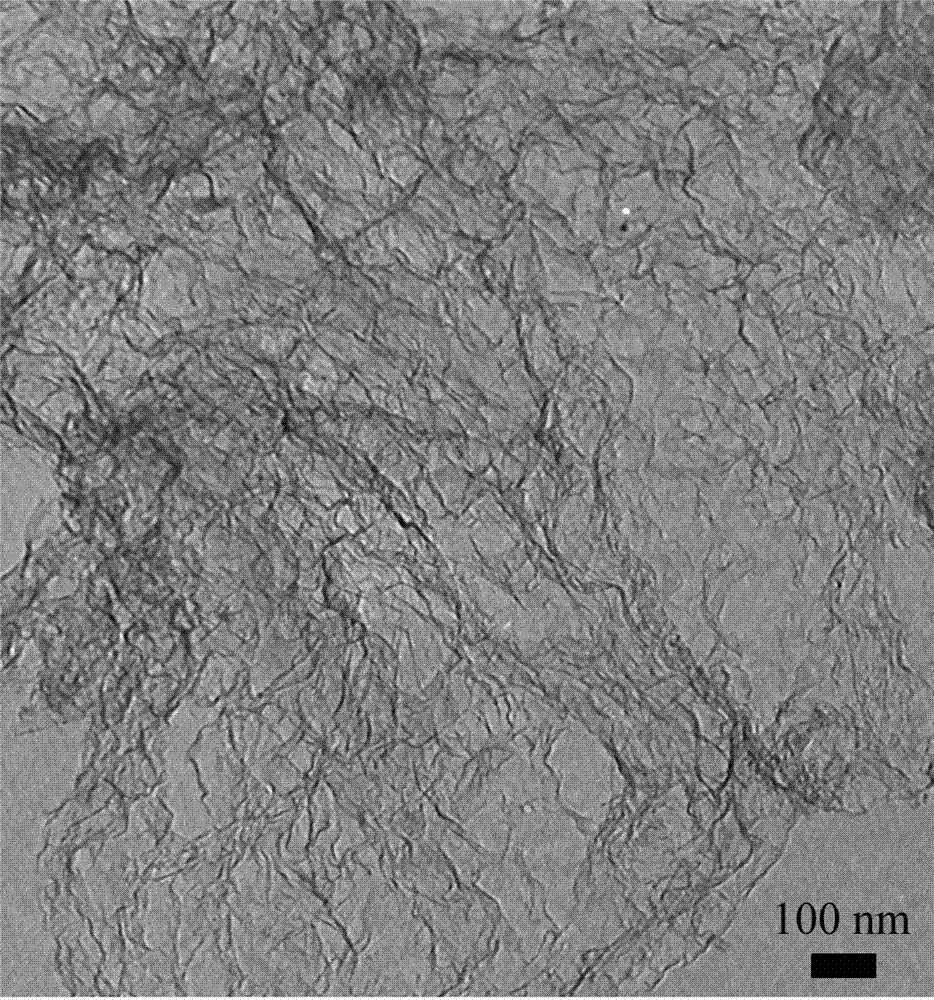

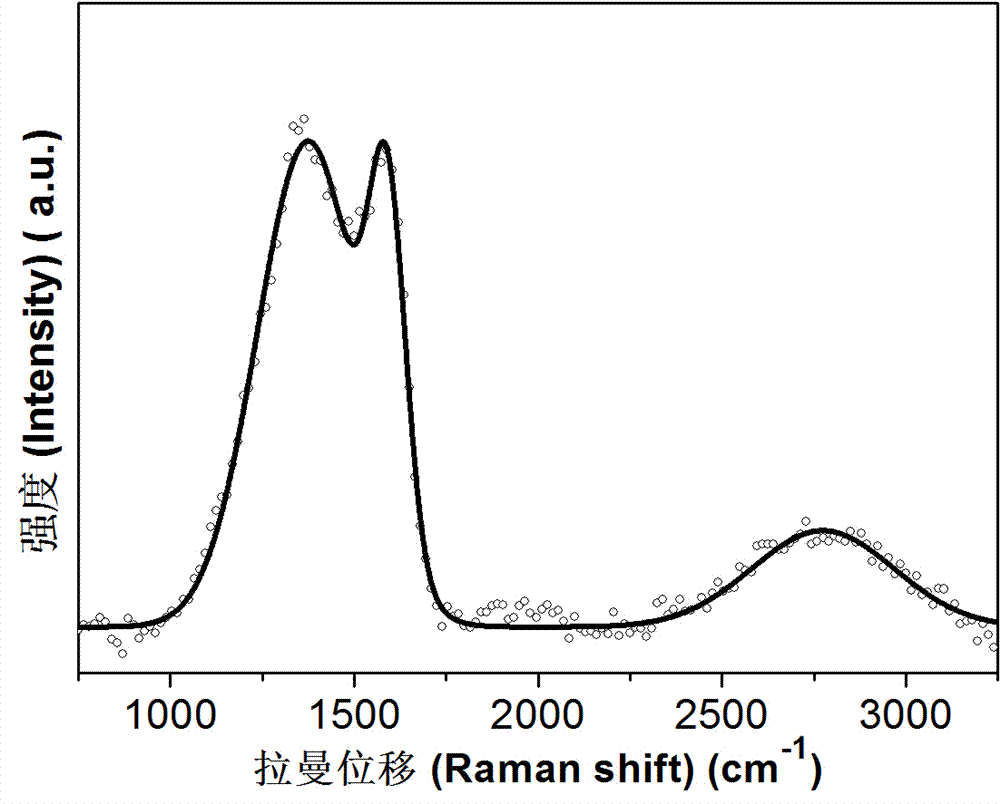

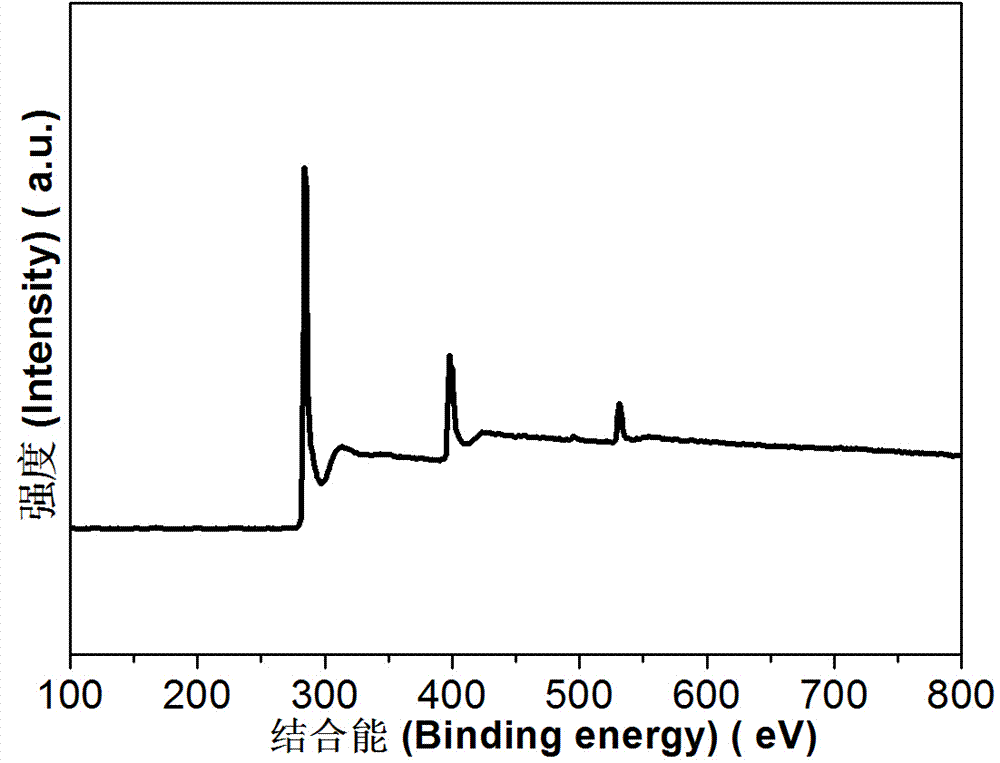

[0018] Melamine and glucose monohydrate were weighed according to the mass ratio of 20:1, and then ground for 30 minutes with an agate mortar; Raise the temperature in the furnace cavity to 450 degrees Celsius at a certain heating rate and keep it warm for 90 minutes, then raise the temperature in the furnace cavity to 800 degrees Celsius at the same heating rate and keep it warm for 60 minutes; after the reaction is over, when the temperature in the furnace cavity is naturally cooled When it reaches room temperature, the product is taken out, which is nitrogen-doped graphene.

Embodiment 2

[0020] Melamine and glucose monohydrate were weighed according to the mass ratio of 20:1, and then ground for 30 minutes with an agate mortar; First raise the temperature in the furnace cavity to 450 degrees Celsius at a certain heating rate and keep it warm for 90 minutes, then raise the temperature in the furnace cavity to 900 degrees Celsius at the same heating rate and keep it warm for 60 minutes; after the reaction, when the temperature in the furnace cavity When naturally cooled to room temperature, the product was taken out, which was nitrogen-doped graphene.

Embodiment 3

[0022] Melamine and glucose monohydrate were weighed according to the mass ratio of 5:1, and then ground for 30 minutes with an agate mortar; First raise the temperature in the furnace cavity to 450 degrees Celsius at a certain heating rate and keep it warm for 90 minutes, then raise the temperature in the furnace cavity to 1000 degrees Celsius at the same heating rate and keep it warm for 60 minutes; after the reaction is over, when the temperature in the furnace cavity When naturally cooled to room temperature, the product was taken out, which was nitrogen-doped graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com