A rapid sequential solidification device for high manganese steel broken wall castings

A sequential solidification and broken wall technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problem of poor impact resistance and wear resistance, many inclusions, and it is difficult to obtain high-quality high manganese steel broken wall Casting and other problems, to avoid shrinkage cavity, solve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

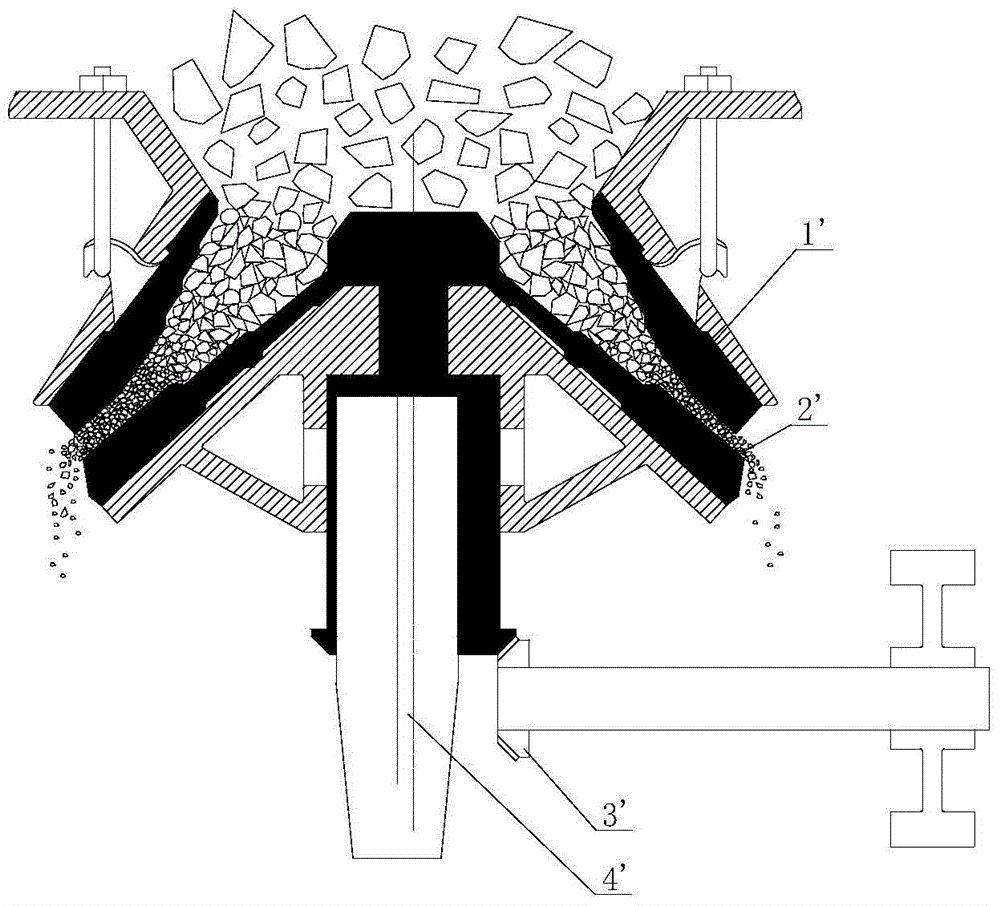

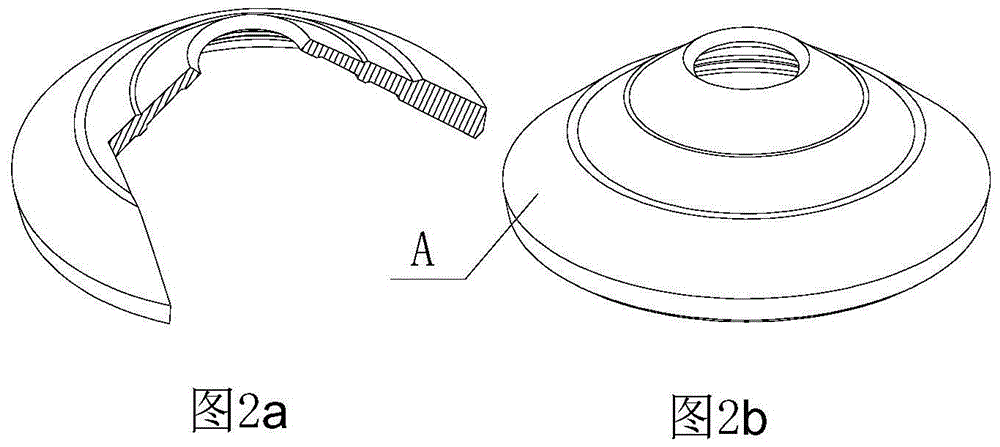

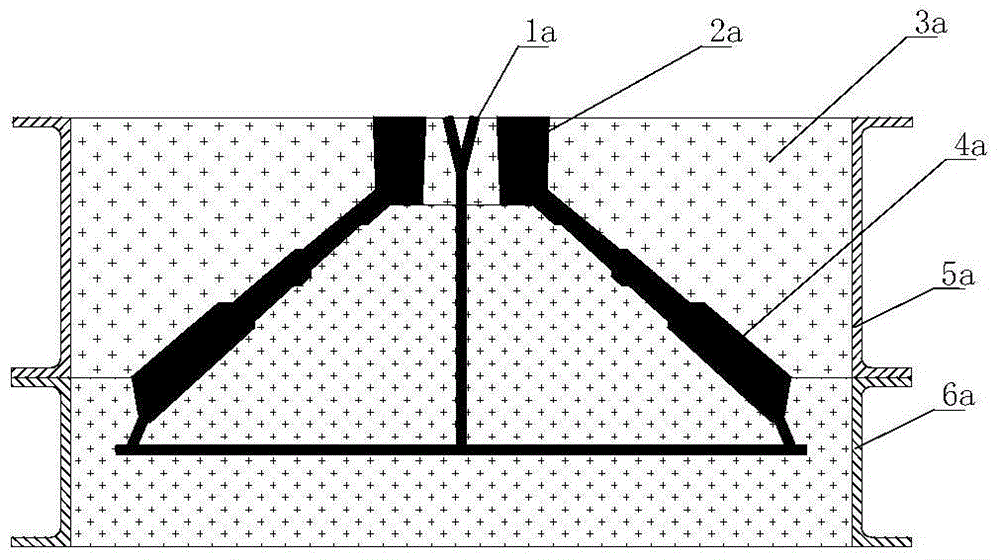

[0032] see Figure 4-12b The overall device in this embodiment includes an upper sand box 3, a sand core 13, and a base. The lower edge of the upper sand box 3 is welded with the upper edge of the quenching block 6 along the inner ring to form a single body. The quenching block 6 forms a quenching process at the initial stage of casting solidification. The effect is to make the important surface of the casting form a good fine-grained structure. The upper sand box 3 and the quenching block 6 are welded into an integral structure such as Figure 8 As shown, B is the weld.

[0033] Such as Figure 5 As shown, the base includes a base frame 11 ( Figure 6a , 6b ), cold type 7 ( Figure 7 ), these two parts form the main body of the base. The cold type 7 forms a circle of water channels 7-1, and the notch of the water channels 7-1 face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com