A rapid sequential solidification technology device for rolling high manganese steel wall castings

A sequential solidification and technical device technology, applied in the field of mechanical equipment manufacturing, can solve the problems of many inclusions, poor impact resistance and wear resistance, coarse grains, etc., to achieve the effect of solving quality and avoiding shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

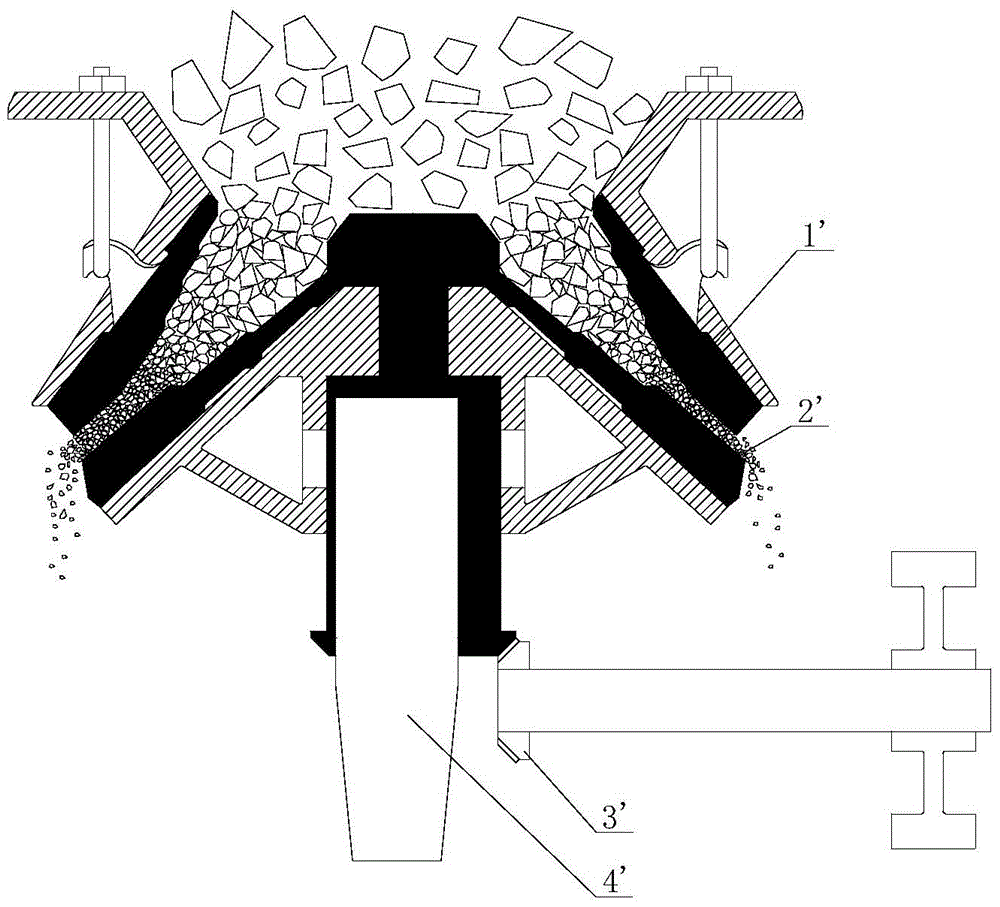

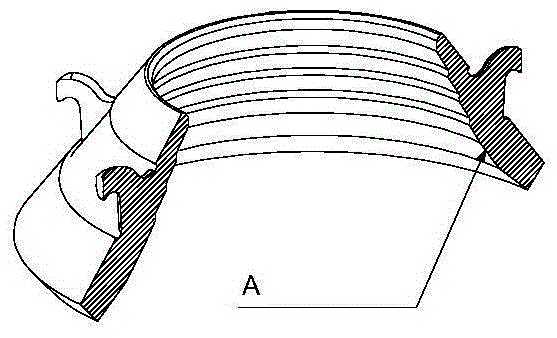

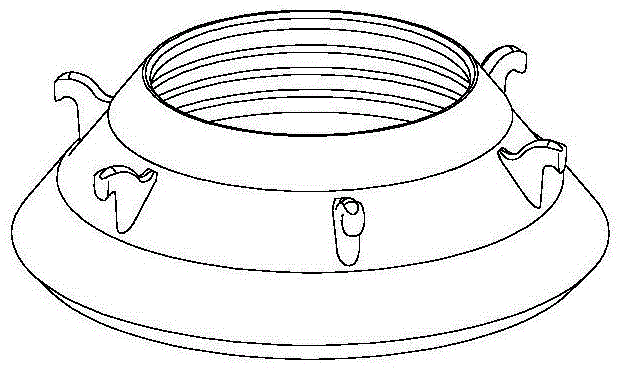

[0031] Such as Figure 4 As shown, the device in this embodiment includes an upper sand box 14, a sand core 5, a base and a loosening mechanism. The base includes a base frame 9 and a cold mold 12. The base frame 9 forms an annular groove 9-1, which is loaded into the cold mold. Type 12, the inner side of the cold type 12 forms an unclosed annular water flow channel 12-1 towards the inside, and the inner side of the water flow channel is sealed by the outer wall of the inner cylinder 9-2 of the base frame 9, between the cold type 12 and the base frame 9 Fixedly connected by several bolts 2, the bolts 2 extend upwards from the bottom of the base frame 9 to the bottom edge of the cold type 12. The contact portion between the cold type 12 and the base frame 9 is packed into the sealing ring 3, and the sealing ring 3 can be adorned with two,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com