Preparation process for white tea

A preparation process and technology of white tea, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of strong taste of white tea, insufficient mellowness, insufficient duration, and insufficient aroma of white tea, so as to facilitate the transformation of contained substances, increase The effect of improving the cell disruption rate and improving the richness and mellowness of the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

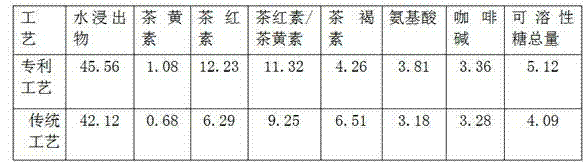

Examples

Embodiment 1

[0023] A white tea preparation process, comprising picking steps, withering steps, rolling steps and drying steps, characterized in that: the withering step is a heating and withering step, specifically: fresh tea leaves are evenly spread in a withering tank for withering , the thickness is 1cm, the withering temperature is controlled at 30°C, and the withering time is 6 hours. Wither until the leaf shape shrinks, the leaf quality is soft, the stems are broken continuously, slightly faint fragrance, and the moisture content is 70%.

[0024] It also includes the far-infrared aroma enhancement step, which is located after the drying step, specifically: use a far-infrared tea aroma enhancer to enhance the aroma, the temperature is controlled at 70 ° C, the time is 9 minutes, the moisture is controlled at 5.0%, and the tea leaves are removed from the machine. Spread out on a cooling rack to cool to room temperature.

[0025] The drying step includes an initial drying step and a fu...

Embodiment 2

[0031] A white tea preparation process, comprising picking steps, withering steps, rolling steps and drying steps, characterized in that: the withering step is a heating and withering step, specifically: fresh tea leaves are evenly spread in a withering tank for withering , the thickness is 1.5cm, the withering temperature is controlled at 36°C, the withering time is 4 hours, wither until the leaf shape shrinks, the leaf quality is soft, the stems are broken continuously, slightly faint fragrance, and the moisture content is 65%.

[0032] It also includes the far-infrared aroma enhancement step, which is located after the drying step, specifically: use a far-infrared tea aroma enhancer to enhance the aroma, the temperature is controlled at 70°C, the time is 9 minutes, the moisture is controlled at 4.5%, and the tea leaves are removed from the machine. Spread out on a cooling rack to cool to room temperature.

[0033] The drying step includes an initial drying step and a full d...

Embodiment 3

[0039] A white tea preparation process, comprising picking steps, withering steps, rolling steps and drying steps, characterized in that: the withering step is a heating and withering step, specifically: fresh tea leaves are evenly spread in a withering tank for withering , the thickness is 1.2cm, the withering temperature is controlled at 32°C, and the withering time is 5 hours. Withering until the leaves are shrunken, the leaves are soft, the stems are broken continuously, and there is a slight fragrance. The water content is 68%.

[0040] It also includes the far-infrared aroma enhancement step, which is located after the drying step, specifically: use a far-infrared tea aroma enhancer to enhance the aroma, the temperature is controlled at 75°C, the time is 8 minutes, the moisture is controlled at 4.8%, and the tea leaves are removed from the machine. Spread out on a cooling rack to cool to room temperature.

[0041] The drying step includes an initial drying step and a ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com