Decorative-material-attached substrate and manufacturing method therefor, touch panel and information display device

A decorative material and a manufacturing method technology, which are applied in identification devices, input/output processes of data processing, instruments, etc., can solve problems such as difficulty in improving optical density, and achieve the effect of small b value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3 and comparative example 1

[0267]

[0268] Black coloring liquid 1 - black coloring liquid 4, white coloring liquid 1, and white coloring liquid 2 described in Table 1 below were prepared using the following materials.

[0269] [Table 1]

[0270]

[0271]

[0272] ・Black dispersion liquid 1 (GB4016, manufactured by Sanyo Pigment Co., Ltd., the following composition)

[0273] Black pigment (carbon black) 25.0% by mass

[0274] Dispersion aid 9.5% by mass

[0275] Dispersion solvent (propylene glycol monomethyl ether acetate) 65.5% by mass

[0276] · Black dispersion liquid 2 (CDP-K106, manufactured by FUJIFILM Electronic Materials Co., Ltd., the following composition)

[0277] Black pigment (titanium dioxide) 25.0% by mass

[0278] Dispersion aid 7.0% by mass

[0279] Dispersion solvent (methyl ethyl ketone) 68.0% by mass

[0280] ・White dispersion (FP White (FP White) B422, manufactured by Sanyo Pigment Co., Ltd., with the following composition)

Embodiment 101

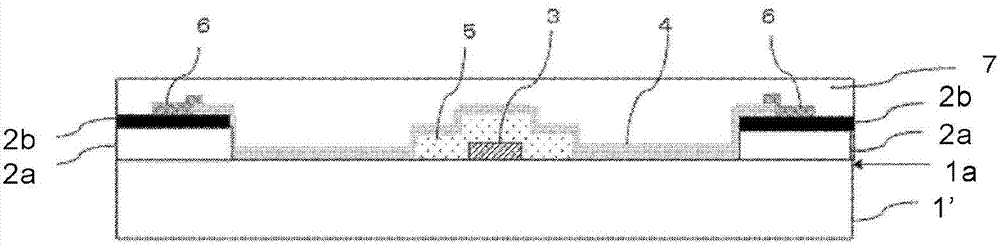

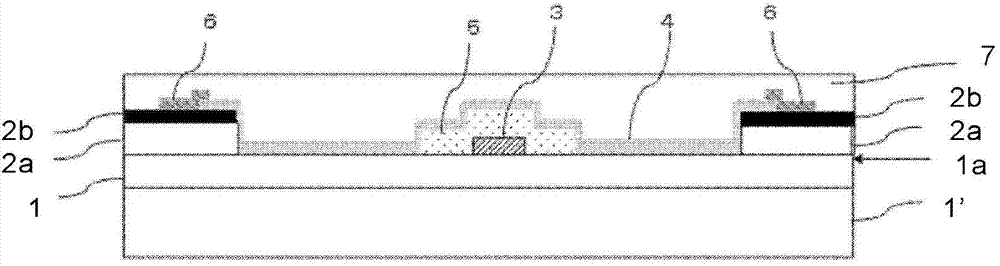

[0363] [Example 101: Production of touch screen]

[0364] "Formation of the first transparent electrode pattern"

[0365]

[0366] The base material with decoration material of each embodiment is introduced into the vacuum chamber, using SnO 2 The ITO target (target) (indium: tin=95:5 (molar ratio)) with a content rate of 10% by mass was subjected to direct current (Direct Current, DC) magnetron sputtering (condition: the temperature of the base material was 250° C. , the argon gas pressure is 0.13Pa, and the oxygen pressure is 0.01Pa) to form an ITO thin film with a thickness of 40nm to obtain a front panel with a transparent electrode layer formed thereon. The surface resistance of the ITO thin film was 80Ω / □.

[0367]

[0368] In the preparation of the white transfer material 1 of the above-mentioned production example 1, the above-mentioned white coloring liquid 1 was replaced with the coating liquid for the photocurable resin layer for etching containing the followi...

Embodiment 106

[0441] The front panel of Example 106 was obtained by performing the same operations as in Example 101, except that the base material with a decorative material of Example 6 was used instead of the base material with a decorative material of Example 1. This front panel is also preferable as the front panels of other embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com