Chamfering tool for cable semiconductor layer

A semi-conductive layer and chamfering tool technology, which is applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of cable terminal failure, poor chamfering quality, low efficiency, etc., and achieve reduced matching errors, strong versatility, The effect of improving the quality of the chamfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described in conjunction with the following examples.

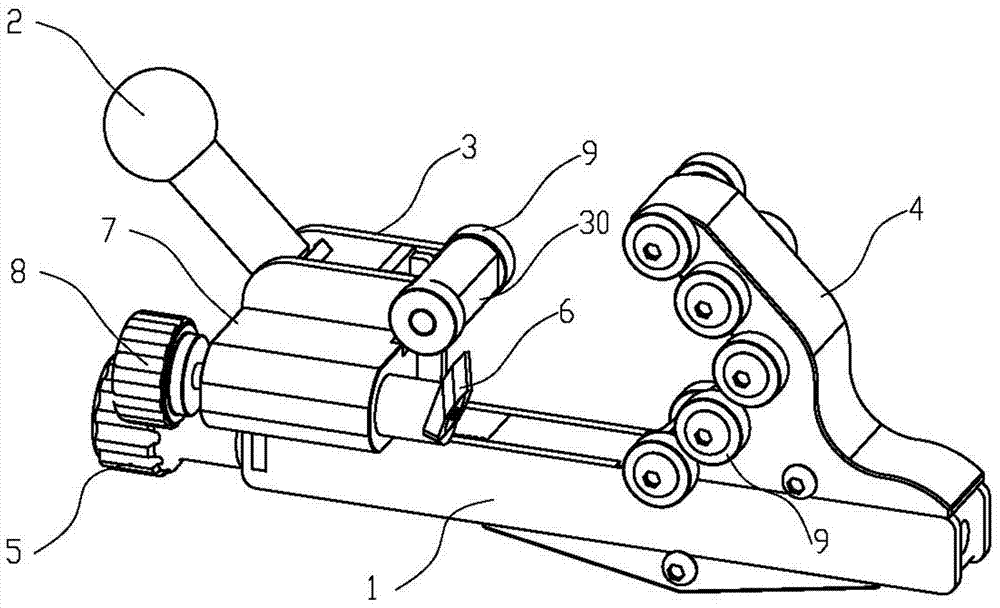

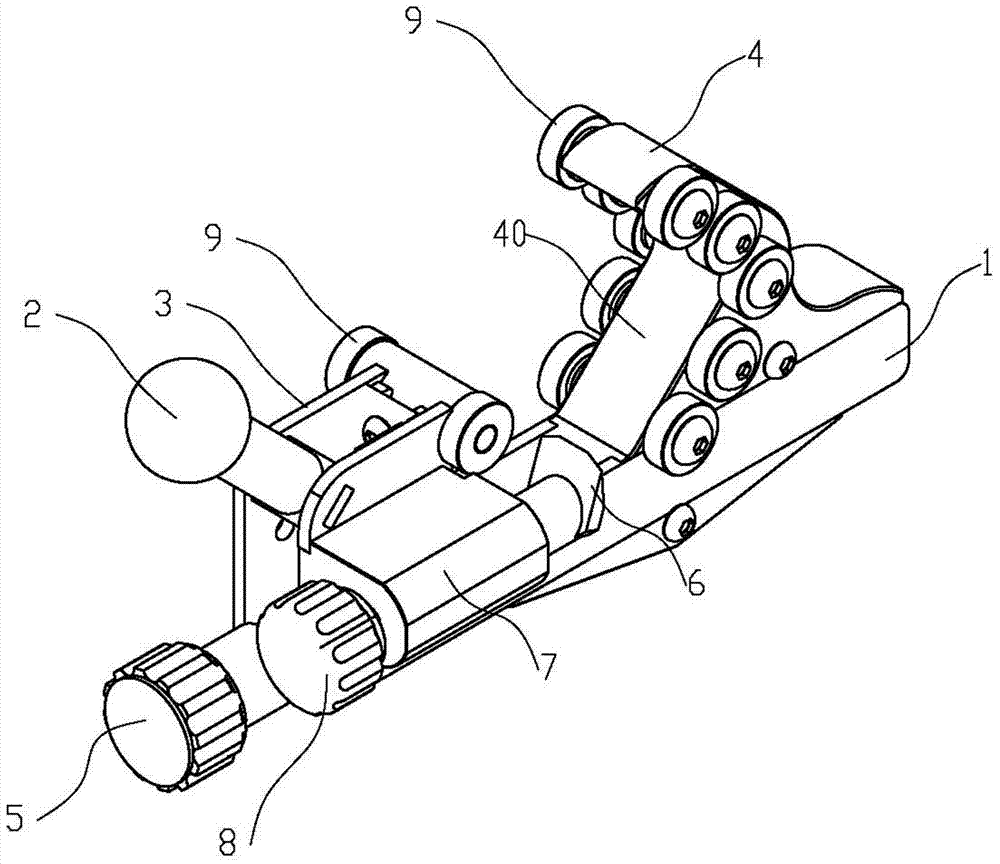

[0030] The cable semiconducting layer chamfering tool created by the present invention, such as figure 1 and figure 2 As shown, it includes a knife rest 1 with a handle 2, a positioning clamp 3 fixedly arranged on the knife rest 1, an arc-shaped clamp 4 arranged opposite to the positioning clamp 3, and a clamping piece arranged on the knife rest 1. The knob 5 , the blade 6 which is slidably arranged on the knife holder 1 through the blade seat 7 , and the feed knob 8 which is arranged on the blade seat 7 .

[0031] Preferably, the arc-shaped clamping piece, the positioning clamping piece and the handle are arranged along the same plane, which is convenient for clamping, and at the same time, it is convenient for the rotary tool to cut the chamfer after clamping.

[0032] In order to facilitate manufacturing and strengthen the structure, the positioning clamp 3 and the tool holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com