A thin ore body mechanized high layered continuous mining method

A mining method and technology for thin ore bodies, which are applied in the field of mechanized high-layered continuous mining of thin ore bodies, can solve the problems of complex mining process, large ore loss and dilution, and high mining cost, and achieve simple mining process structure and low ore loss. The effect of miniaturization and short operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] In a silver deposit, the No. I main ore body has an elevation of 2431-1800m, an average dip angle of 65°, and an average thickness of 2-3m. The stability of the ore body and hanging wall rocks is average; the average Ag grade of the ore is 277g / t.

[0044] The steps of adopting the mechanized upward and high-layer filling method in the middle section of 1800m are as follows:

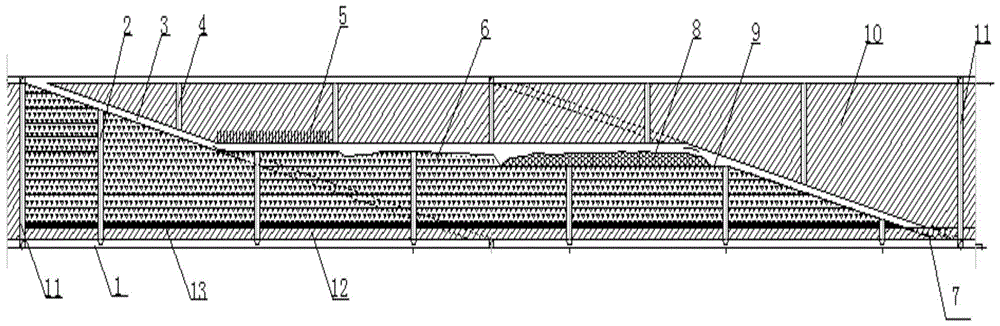

[0045]a) The height of the middle section from 1800m to 1840m is 40m, and the vein is divided into multiple parallelogram ore blocks by an intra-vein slope with a slope of 20% every 200m along the ore body. The middle section of 1800m is divided into four ore blocks. Each ore block is equally divided into mine house 10 and bottom pillar 12, stay 5m high bottom pillar 12.

[0046] b) Arrange a pedestrian ventilation patio 11 at the end of the first mining block; arrange a filling patio 4 every 50m from the pedestrian ventilation patio 11; arrange a 2×2m above the bottom column 12 2 use this as a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com