Pressure weight type roof communication tower and mounting method

A technology of communication tower and weight type, which is applied in the field of communication equipment, can solve the problems of communication tower dismantling, difficulty in moving, long construction period of communication tower, poor mobility of communication tower, etc., so as to achieve easy acceptance by the other party, convenient handling and low erection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

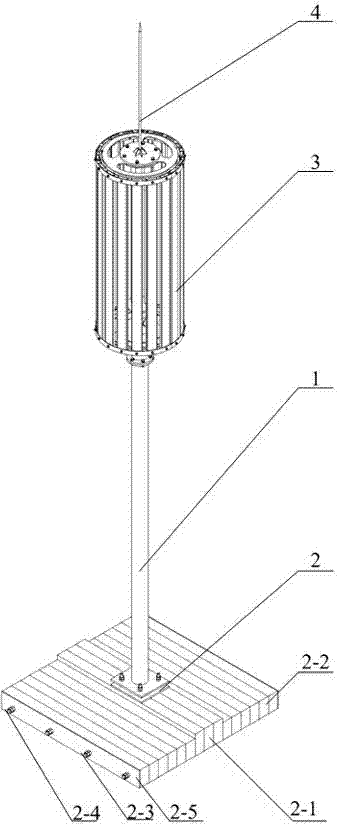

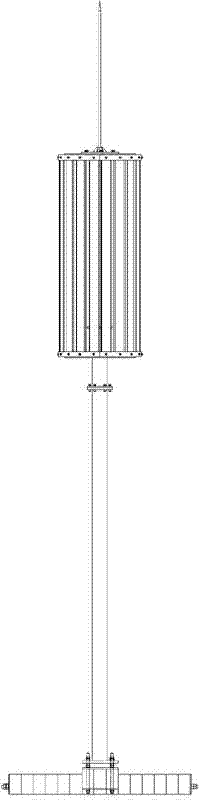

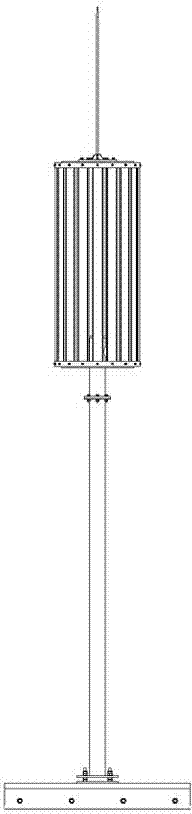

[0029] Such as Figures 1 to 5 As shown, the pressure-heavy roof communication tower of the present invention is mainly erected on the roof or roof as a carrier for antenna installation of various operators. Including column 1, base 2, radome steel structure 3 and lightning rod 4. The column 1 is connected and fixed with the base 2 through the connecting flange at the bottom, and the connecting flange at the top of the column 1 is connected with the radome steel structure 3, which is used for installing various antennas; the lightning rod 4 is connected with the top of the antenna mounting frame 3 Flange connection. A plurality of glass steel bars are installed on the outer circumference of the radome steel structure 3, which has good wave permeability, strong outdoor aging resistance, and good wind resistance, which can strengthen the protection of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com