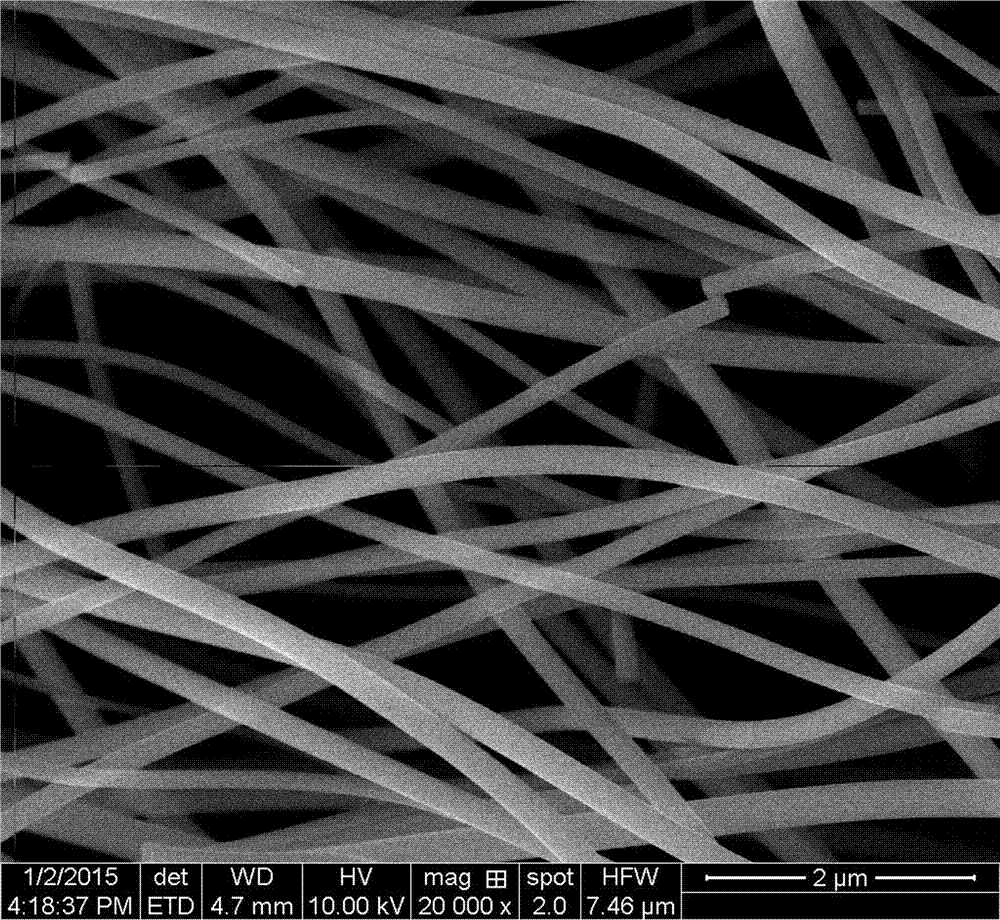

Preparation method of TiO2 nano fibers with adjustable crystal phase

A technology of nanofibers and crystal phases, applied in the field of nanomaterials and photocatalysis, can solve the problems of increasing the cost and operation difficulty of electrospinning devices, difficult to solve titanium source hydrolysis, and hindering the spinning process, so as to improve spinnability and avoid Hydrolysis, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 0.45g of polyvinylpyrrolidone and dissolve it in 7mL of absolute ethanol, stir until completely dissolved to form a uniform and transparent solution, add 2 mL of glacial acetic acid dropwise to the solution, stir well, and then add 1mL of isopropyl titanate , after completely stirring to form a light yellow liquid, add 240 μL of deionized water dropwise within 1 minute, and stir for 30 minutes to completely hydrolyze the isopropyl titanate to form a uniform and transparent light yellow clear spinning solution;

[0034](2) Draw the spinning solution prepared in step (1) into the syringe for spinning. The diameter of the needle of the syringe is 0.8mm, the temperature and humidity in the room are 29°C and 12%, respectively, and the distance between the needle and the receiver is adjusted to 15cm. The propulsion speed of the silk liquid is 1.44mL / h, the voltage of the electrospinning process is 17.5kV, and the as-spun TiO 2 Nanofibers;

[0035] (3) TiO obtained ...

Embodiment 2

[0038] (1) Weigh 0.57g of polyvinylpyrrolidone and dissolve it in 7mL of absolute ethanol, stir until completely dissolved to form a uniform and transparent solution, add 1mL of glacial acetic acid dropwise to the solution, stir well, then add 1mL of isopropyl titanate, After completely stirring and forming a light yellow liquid, add 180 μL of deionized water dropwise within 45 seconds, and stir for 60 minutes to completely hydrolyze the isopropyl titanate to form a uniform and transparent light yellow clear spinning solution;

[0039] (2) Draw the spinning solution prepared in step (1) into the syringe for spinning. The diameter of the syringe needle is 0.8mm, the temperature and humidity in the room are 20°C and 55% respectively, and the distance between the needle and the receiver is adjusted to 12cm. The propulsion speed of the silk liquid is 1.44mL / h, the voltage of the electrospinning process is 15kV, and the as-spun TiO 2 Nanofibers;

[0040] (3) TiO obtained in step (...

Embodiment 3

[0042] (1) Weigh 0.67g of polyvinylpyrrolidone and dissolve it in 7mL of absolute ethanol, stir until completely dissolved to form a uniform and transparent solution, add 2.5mL of glacial acetic acid dropwise to the solution, stir well, and then add 1mL of isopropyl titanate , after completely stirring to form a light yellow liquid, add 240 μL of deionized water dropwise within 1 min, and stir for 30 min to completely hydrolyze the isopropyl titanate to form a uniform and transparent light yellow clear spinning solution;

[0043] (2) Draw the spinning solution prepared in step (1) into the syringe for spinning. The diameter of the needle of the syringe is 0.8mm, the temperature and humidity in the room are 24.3°C and 28% respectively, and the distance between the needle and the receiver is adjusted to 14cm. The propulsion speed of the silk liquid is 1.44mL / h, the voltage of the electrospinning process is 16kV, and the as-spun TiO 2 Nanofibers;

[0044] (3) TiO obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com