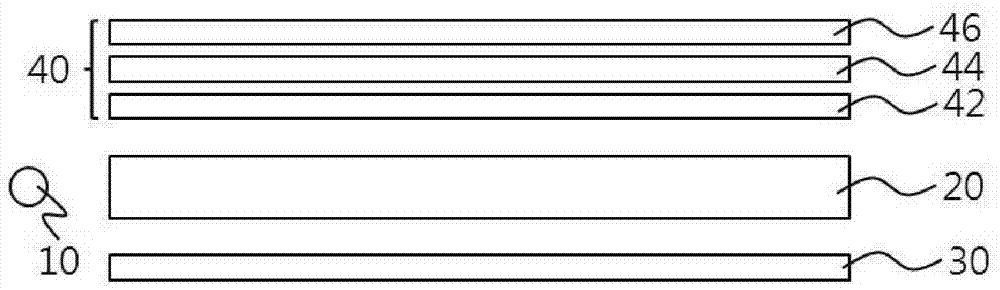

Light Guide Plate and Method for Fabricating the Same

A light guide plate, aromatic technology, applied in the field of manufacturing the light guide plate, can solve problems such as side reactions, achieve the effects of reducing color deviation, thermal stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0069] Preparation Example 1: Preparation of Aromatic Polycarbonate Resin

[0070] 2,2-bis(4-hydroxyphenyl)propane ("bisphenol A", BPA), diphenyl carbonate (DPC), and 150 ppb KOH as catalyst (refer to the number of moles of bisphenol A) as listed in Table 1 The obtained content ratio (molar ratio) was placed sequentially, followed by removal of oxygen with nitrogen. Then, the reactor was heated to 160°C, heated again to 190°C, and the reaction was performed for 6 hours. After 6 hours, the reactor was heated again to 210°C and maintained at 100 Torr for 1 hour. Then, the reactor was heated again to 260° C. and maintained at 20 Torr for 1 hour, then depressurized to 0.5 Torr and maintained for 1 hour, thereby preparing an aromatic polycarbonate resin (yield: 99.9%). The weight average molecular weight, terminal hydroxyl group content, melt index (MI) and spiral flow of the prepared aromatic polycarbonate resins were measured, and the results are shown in Table 1.

preparation Embodiment 2

[0071] Preparation Example 2: Preparation of Aromatic Polycarbonate Resin

[0072] An aromatic polycarbonate resin was prepared in the same manner as in Preparation Example 1 (yield: 99.9%), except that the amounts of 2,2-bis(4-hydroxyphenyl)propane and diphenyl carbonate were listed in Table 1 Adjustment. The weight average molecular weight, terminal hydroxyl group content, melt index (MI) and helical flow of the prepared aromatic polycarbonate resins were measured, and the results are shown in Table 1.

preparation Embodiment 3

[0073] Preparation Example 3: Preparation of Aromatic Polycarbonate Resin

[0074] An aromatic polycarbonate resin was prepared in the same manner as in Preparation Example 1 (yield: 99.9%), except that the amounts of 2,2-bis(4-hydroxyphenyl)propane and diphenyl carbonate were listed in Table 1 Adjustment. The weight average molecular weight, terminal hydroxyl group content, melt index (MI) and helical flow of the prepared aromatic polycarbonate resins were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com