A kind of gas generating agent composition and preparation method thereof

A technology of gas generating agent and composition, which is applied in the generation of compressed gas and attacking equipment, etc. It can solve the problems of increased residue amount and reduced gas production efficiency, and achieves the effects of advanced decomposition temperature, reduced gas production efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

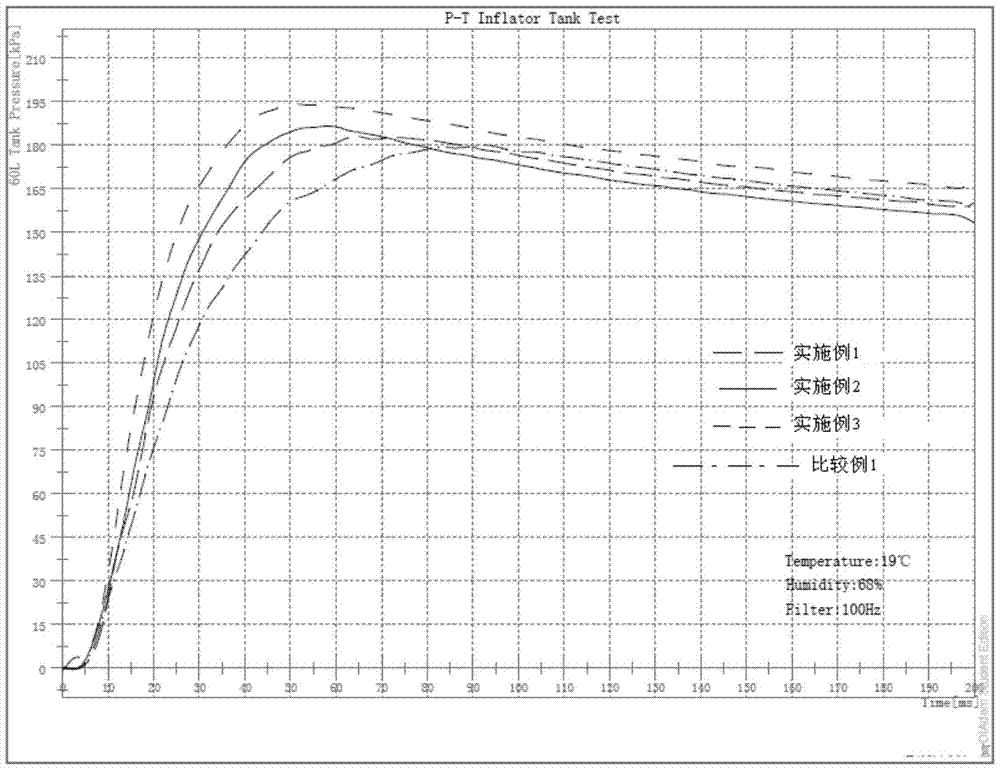

Examples

Embodiment 1

[0039] The gas generating agent composition described in this embodiment adopts the following raw material components:

[0040] Fuel guanidine nitrate, 44g;

[0041] Oxidant basic copper nitrate, 47g;

[0043] Azotetrazolium biguanide, 2g;

[0044] Silicon dioxide, 1g;

[0045] Binder polyethylene glycol, 2g.

[0046] The preparation method of described gas generant composition, it comprises the steps:

[0047] Take the guanidine nitrate, basic copper nitrate, cerium oxalate, biguanidine azotetrazolium and silicon dioxide respectively according to the above weight, mix them uniformly, add the binder polyethylene glycol, granulate, dry at 60°C, press Slice and serve.

Embodiment 2

[0049] The gas generating agent composition described in this embodiment adopts the following raw material components:

[0050] Fuel guanidine nitrate, 40g;

[0051] Oxidant basic copper nitrate, 50g;

[0053] Ammonium azotetrazolium, 7g;

[0054] Binder sodium carboxymethylcellulose, 2g.

[0055] The preparation method of described gas generant composition, it comprises the steps:

[0056] According to the above weight, take the guanidine nitrate, basic copper nitrate, cerium oxalate and ammonium azotetrazolium respectively, mix them evenly, add the binder sodium carboxymethyl cellulose, granulate, dry at 60°C, and press into tablets to obtain .

Embodiment 3

[0058] The gas generating agent composition described in this embodiment adopts the following raw material components:

[0059] Fuel guanidine nitrate, 42g;

[0060] Basic copper nitrate, 46g;

[0061] Cerium oxalate, 2g;

[0062] Azotetrazolium biguanidine, 5g;

[0063] The slagging agent is a mixture of alumina and kaolin, wherein 3g of alumina and 1g of kaolin;

[0064] Binder sodium carboxymethylcellulose, 1 g.

[0065] The preparation method of described gas generant composition, it comprises the steps:

[0066] Take the guanidine nitrate, basic copper nitrate, cerium oxalate, biguanidine azotetrazolium, alumina and kaolin according to the above weight respectively, mix them uniformly, add the binder sodium carboxymethyl cellulose, granulate and heat at 60°C Drying and pressing into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com