Hot pickled mustard tuber continuous dehydration centrifugal separator with bottom upwards

A centrifuge and reverse buckle technology, which is applied to centrifuges, centrifuges with rotating drums, etc., can solve the problems of inability to achieve convenience and continuity, low work efficiency, etc., and achieve good cleaning, strong dehydration, and The effect of high degree of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

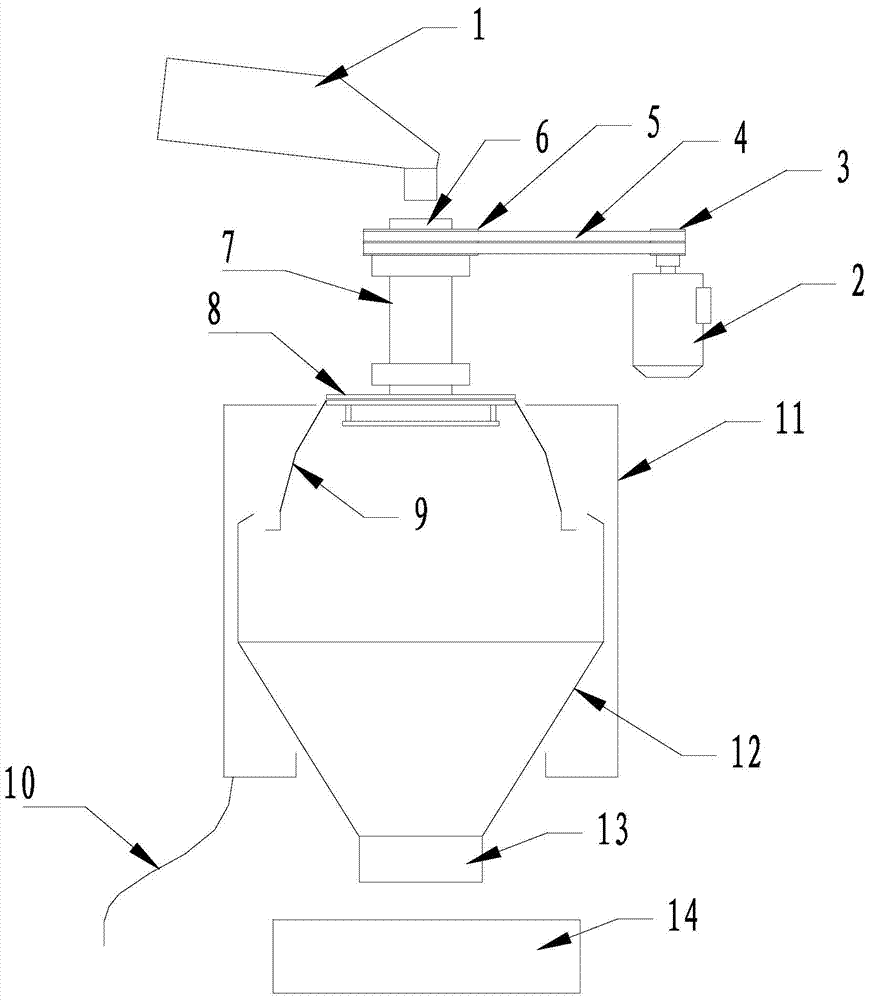

[0022] Such as figure 1 As shown, the upside-down mustard mustard continuous dehydration centrifuge includes a vibrating hopper 1 for conveying mustard materials, a hollow shaft 6 for holding materials, and a shaft sleeve 7 is arranged outside the hollow shaft, and the motor 2 rotates through a power transmission device. The power is transmitted to the hollow shaft 6 . The power transmission device includes a small pulley 3 arranged at the end of the motor 2, a large pulley 5 arranged at the end of the hollow shaft 6, and a V-belt 4 connecting the two.

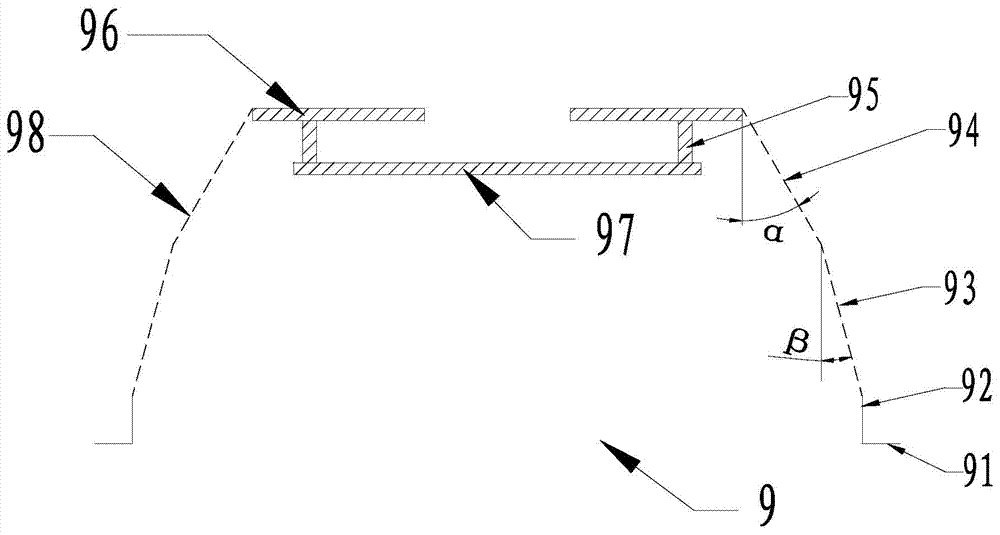

[0023] A hollow rotating disk 8 is arranged at the lower end of the hollow shaft 6, and a rotating drum 9 is mounted on the lower end of the hollow disk 8 by an undercut. The lower end of the drum 9 is provided with an inner tube 12 for receiving the pickled mustard material thrown out by the drum 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com