A kind of manufacturing method of composite material grinding roller

A composite material and manufacturing method technology, applied in grain processing and other directions, can solve the problems of fast wear speed, high brittleness of wear-resistant materials, limited adhesion, etc., and achieve the effect of improving service life, avoiding displacement, and not easy to peel off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

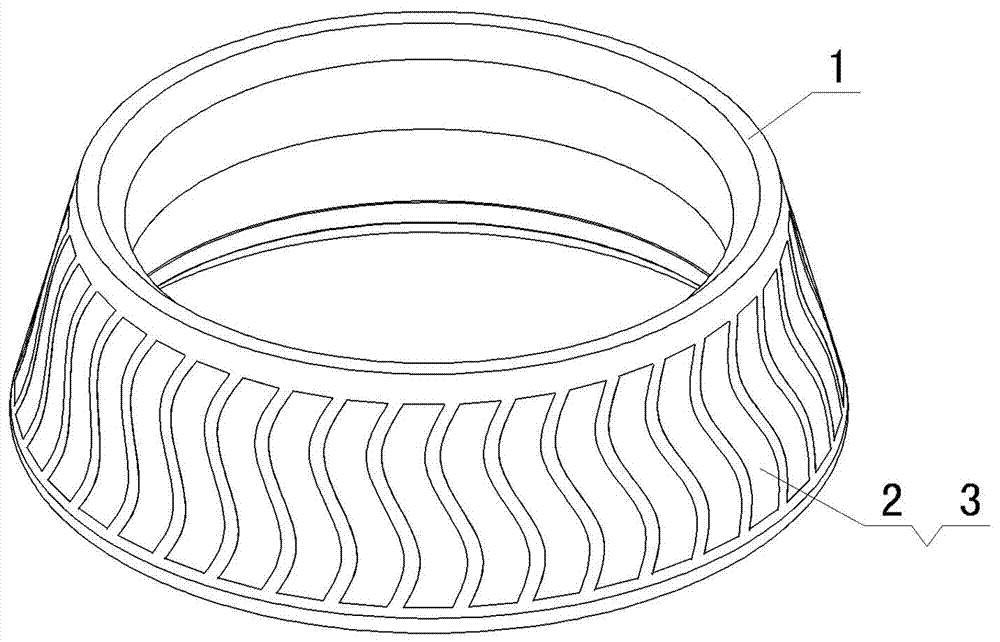

[0046] First of all, according to the wear surface of the conical grinding roller (about 0.5 tons), the embedded wavy ceramic reinforcement is designed;

[0047] Then, mix ceramic particles with a diameter of 0.1 to 3 mm with a binder, fill them into a mold, and solidify to obtain a wave-shaped ceramic reinforcement 3 with a multi-scale pore configuration inside;

[0048] Then, a number of wave-shaped ceramic reinforcements 3 are closely arranged on the working surface of the grinding roller casting cavity, and the iron alloy is cast for compounding;

[0049] Finally, after cooling, the sand is cleaned and polished to obtain a conical composite material grinding roller, such as Figure 1-Figure 3 shown.

Embodiment 2

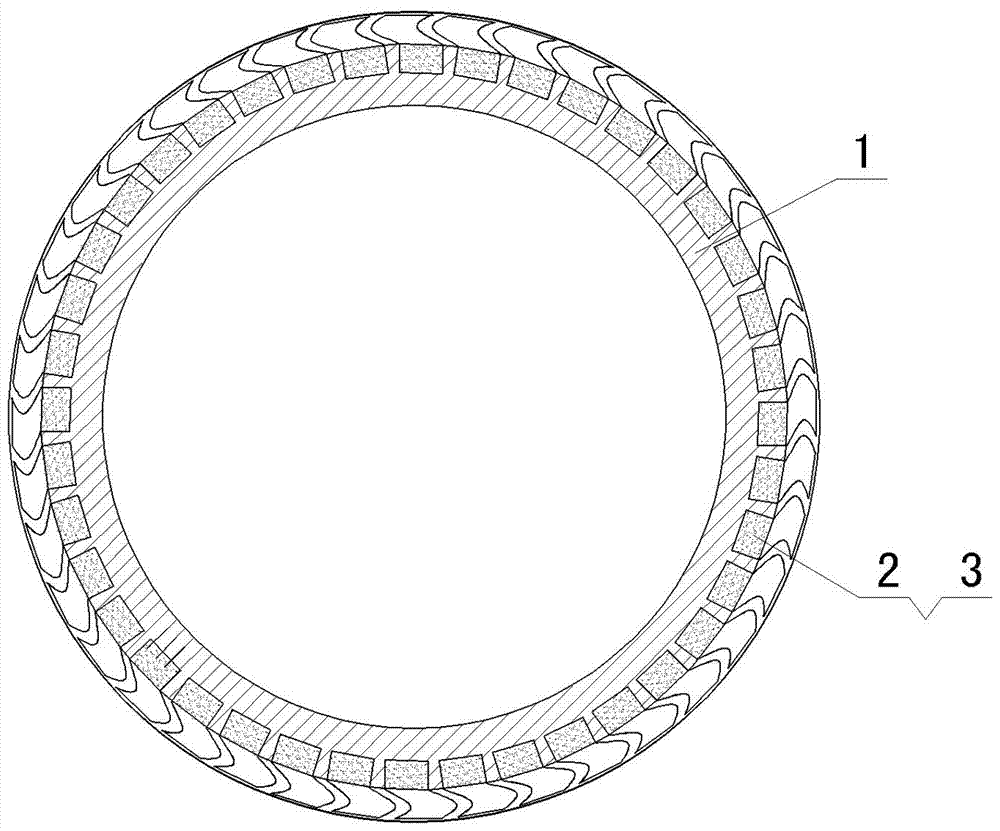

[0051] First of all, according to the wear surface of the tire-type grinding roller (about 4 tons), the embedded wavy ceramic reinforcement is designed;

[0052] Then, mix ceramic particles with a diameter of 2 to 6 mm with a binder, fill them into a mold, and solidify to obtain a wave-shaped ceramic reinforcement 3 with a multi-scale pore configuration inside;

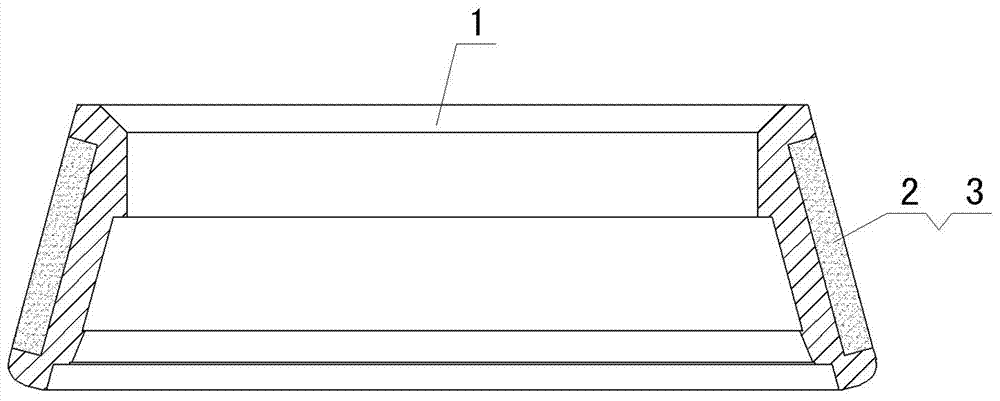

[0053] Then, put the corrugated ceramic reinforcement 3 into a cavity with a size close to it, and cast high-chromium cast iron to obtain a corrugated composite 2, such as Figure 4 and Figure 5 shown;

[0054] Then, a number of wave-shaped composite bodies 2 are closely arranged on the working surface of the grinding roller casting cavity, and alloy steel is cast for secondary compounding;

[0055] Finally, after cooling, the sand is cleaned and polished to obtain tire-type composite material grinding rollers, such as Figure 6 and Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com