Method for preparing stuffed meatball by making use of beef processing by-products

A technology for meat and by-products, which is applied in the field of preparing meatballs with heart, can solve the problems of single product variety, less processed food, complicated process, etc., and achieve the effects of increasing added value, harmonizing taste, and improving nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

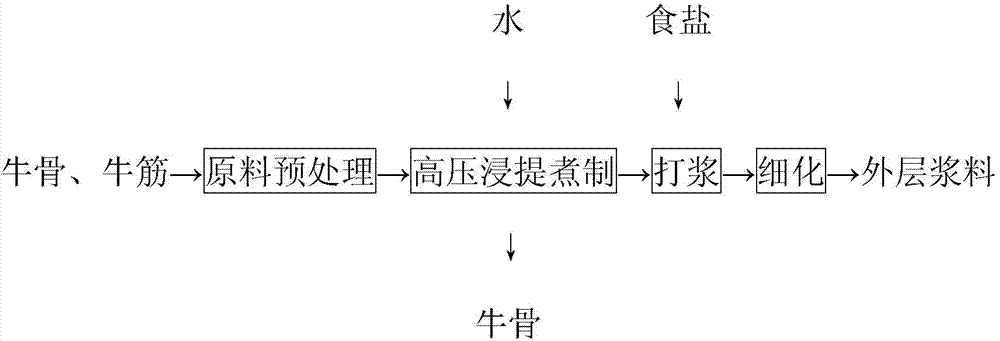

[0038] figure 1 Shown is the flow chart of the preparation of outer layer slurry in the present invention;

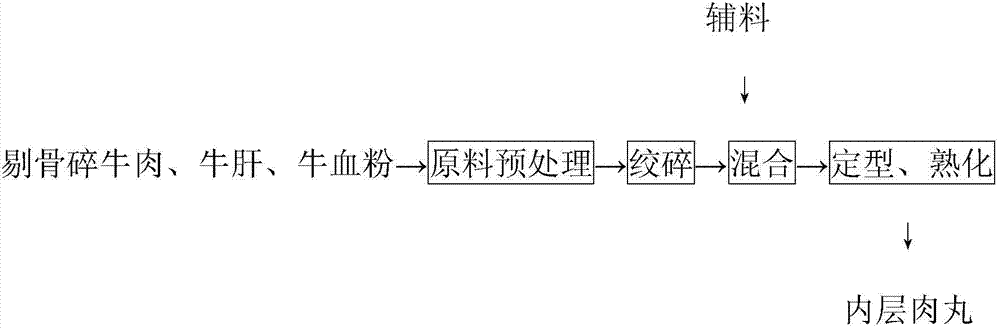

[0039] figure 2 Shown is the flow chart of the preparation of inner layer meatball among the present invention;

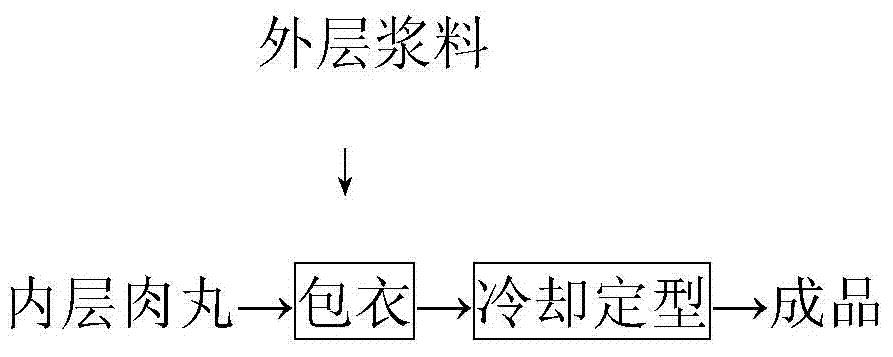

[0040] image 3 Shown is the flow chart of the preparation of heart-wrapped meatball among the present invention;

[0041] The present invention will be described in further detail below in combination with specific embodiments.

[0042] The production process for preparing heart-wrapped meatballs using beef processing by-products can include three parts, and the specific process is as follows:

[0043] (1) Preparation of outer layer slurry (see figure 1 )

[0044] (2) Preparation of inner meatballs (see figure 2 )

[0045] (3) Preparation of Baoxin Meatballs (see image 3 )

[0046] The specific operation points are introduced in order as follows:

[0047] ⑴ Preparation of outer layer slurry

[0048] ① Raw material pretreatment

[0049] Remov...

Embodiment 1

[0071] ⑴ Preparation of outer layer slurry

[0072] ① Raw material pretreatment

[0073] Remove the fascia attached to the beef bone, take 95 parts of the beef bone, wash and set aside; take 25 parts of the beef tendon, wash, cut into small particles with a particle size of about 3 cm for later use;

[0074] ②High pressure extraction and cooking

[0075] Mix beef bone and beef tendon granules, and carry out high-pressure extraction and cooking with a material-liquid ratio of 1:4 (m:m, the weight of solid material is calculated as the total of beef bone and beef tendon). The processing temperature is 120°C, and the processing time is 65 minutes. After processing, remove the beef bones and keep the beef tendon feed liquid for later use;

[0076] ③Beating

[0077] Add 0.8 part of salt to the beef tendon feed liquid after high pressure treatment, then beat the beating until no obvious granular matter;

[0078] ④ Refinement

[0079] The material after beating is placed in a co...

Embodiment 2

[0093] ⑴ Preparation of outer layer slurry

[0094] ① Raw material pretreatment

[0095] Remove the fascia attached to the beef bones, take 110 parts of beef bones, wash them for later use; take 35 parts of beef tendons, wash them, cut them into small particles with a particle size of about 4 cm for later use;

[0096] ②High pressure extraction and cooking

[0097] Mix beef bone and beef tendon granules, and carry out high-pressure extraction and cooking at a material-to-liquid ratio of 1:5 (m:m, the weight of solid material is calculated as the total of beef bone and beef tendon). After processing, remove the beef bones and keep the beef tendon feed liquid for later use;

[0098] ③Beating

[0099] Add 1.2 parts of salt to the beef tendon feed liquid after high-pressure treatment, and then perform beating until there is no obvious granular matter;

[0100] ④ Refinement

[0101] The material after beating is placed in a colloid mill for refinement, the gap size is 50 μm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com