Lactating sow feed

A technology for sow feed and lactation, applied in the fields of lactating sow feed and livestock feed, can solve the problems of low weaning weight of piglets and the inability of lactating sows to exert their lactation potential, so as to increase profits, increase the body weight of weaned individuals, and realize regulation and control. The effect of nutritional balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

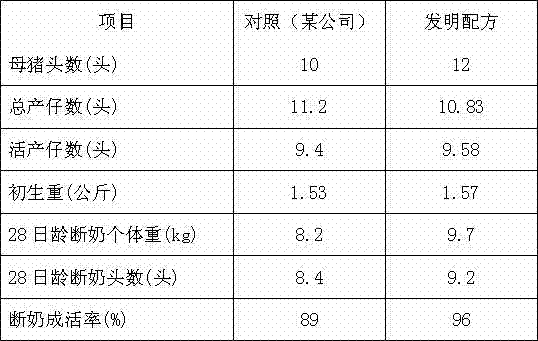

[0014] In a large pig farm in Hebei Province. From the 90th day of gestation of sows to the end of weaning of piglets (28 days), a total of 52 days.

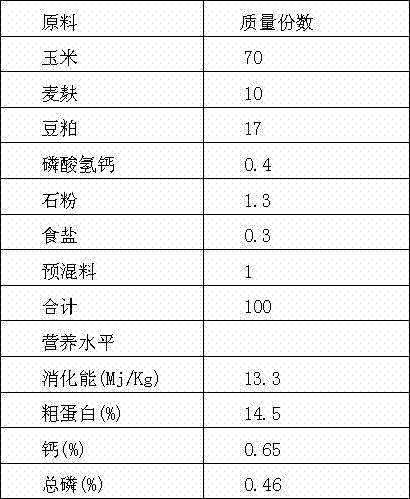

[0015] A total of 24 healthy sows of the same breed and with similar litter performance were selected and randomly divided into 2 treatment groups, with 12 replicates in each treatment group and 1 sow in each replicate. The control group is the diet of a certain company, and the test group is the formula diet of the invention. See Table 1 for formula and nutritional level of lactating pig feed of the present invention.

[0016] Table 1 Feed composition and nutrient composition of lactating sows (%)

[0017]

[0018] Among them, the composition of the premix is calculated as 1kg: ferrous sulfate monohydrate 23g, copper sulfate pentahydrate 1.8g, zinc sulfate monohydrate 12g, manganese sulfate monohydrate 2.5g, calcium iodate 1.2g, sodium selenite 0.9g , Sodium Butyrate 300g, Niacin 900mg, VA 400mg, VD 40mg, VE 1100mg, VK1...

Embodiment 2

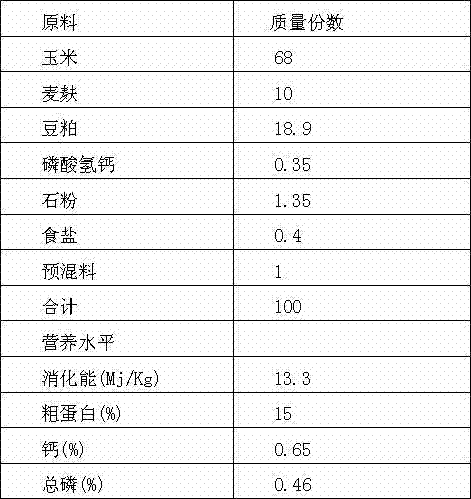

[0028] Lactating sow feed composition and nutrient composition table (%)

[0029]

[0030] Among them, the composition of the premix is calculated as 1kg: ferrous sulfate monohydrate 23g, copper sulfate pentahydrate 1.8g, zinc sulfate monohydrate 12g, manganese sulfate monohydrate 2.5g, calcium iodate 1.2g, sodium selenite 0.9g , Sodium Butyrate 300g, Niacin 900mg, VA 400mg, VD 40mg, VE 1100mg, VK180mg, B 1 90mg, riboflavin 320mg, VB 12 130mg, pantothenic acid 1300mg, folic acid 50mg, biotin 450mg, zeolite powder 653.64g.

Embodiment 3

[0032] Lactating sow feed composition and nutrient composition table (%)

[0033] raw material parts by mass corn 67 Wheat bran 10 soybean meal 19.95 Calcium hydrogen phosphate 0.31 stone powder 1.34 salt 0.4 Premix 1 total 100 nutritional level Digestible energy (Mj / Kg) 13.3 Crude protein (%) 15.5 calcium(%) 0.65 Total phosphorus (%) 0.46

[0034] Among them, the composition of the premix is calculated as 1kg: ferrous sulfate monohydrate 23g, copper sulfate pentahydrate 1.8g, zinc sulfate monohydrate 12g, manganese sulfate monohydrate 2.5g, calcium iodate 1.2g, sodium selenite 0.9g , Sodium Butyrate 300g, Niacin 900mg, VA 400mg, VD 40mg, VE 1100mg, VK180mg, B 1 90mg, riboflavin 320mg, VB 12 130mg, pantothenic acid 1300mg, folic acid 50mg, biotin 450mg, zeolite powder 653.64g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com