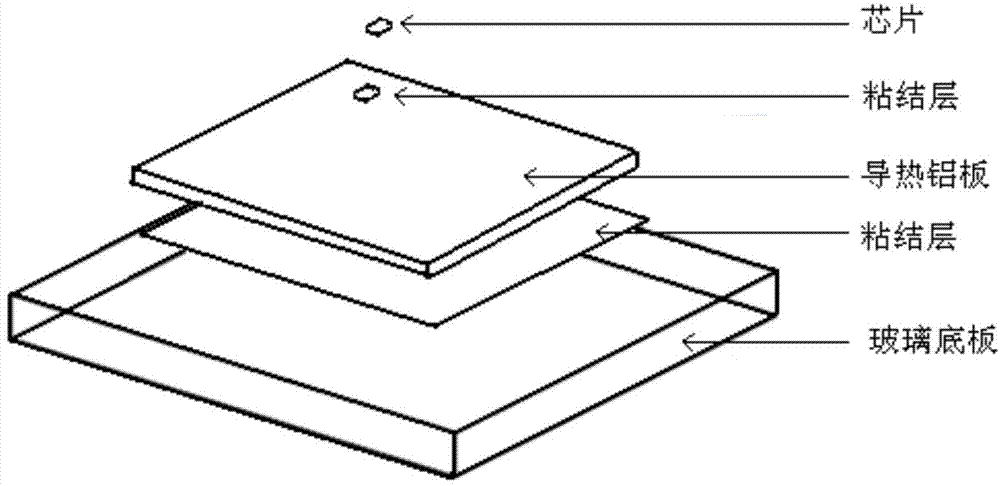

Cooling glass bottom plate of high-concentration photovoltaic power generation module receiver and preparation method of cooling glass bottom plate

A glass bottom plate, photovoltaic power generation technology, applied in photovoltaic power generation, glass manufacturing equipment, photovoltaic modules and other directions, can solve the problems of insufficient light transmittance, easy deformation of glass patterns, insufficient whiteness, etc. Power generation efficiency and cost performance, reasonable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

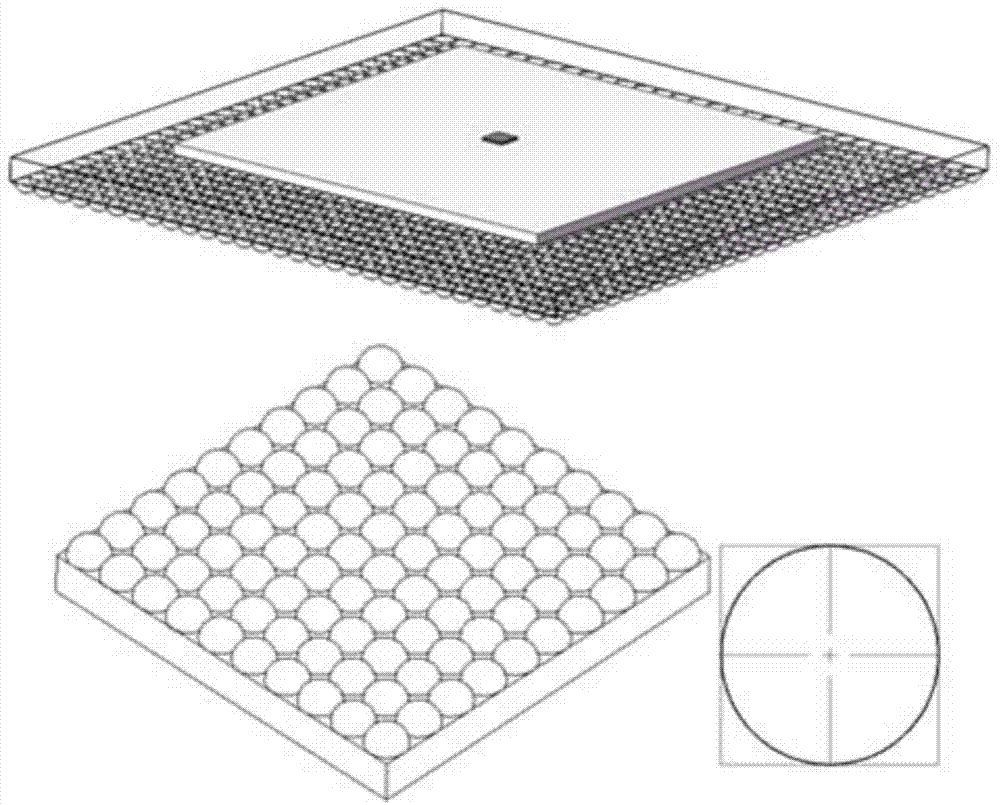

[0043] In this embodiment, a heat-dissipating glass bottom plate of a receiver for a high-power concentrating photovoltaic power generation module, the surface of the heat-dissipating glass bottom plate in contact with the air is composed of an array of curved geometric shapes arranged in a certain order. The curved body is a hemispherical body arranged in a two-dimensional square (that is, the hemispherical body is inscribed with the square) to form the contact surface between the heat dissipation glass bottom plate and the air (such as figure 2 mentioned).

[0044] If the side length of the square tangent to the hemisphere is 2r, the radius of the sphere is r

[0045] Then the effective heat dissipation area of the hemispheroid arranged in a two-dimensional square is:

[0046] It is multiplied by the base area of the square:

[0047] The design specification of the glass backplane in this embodiment is 60x60x3.2mm, the design specification of the hemispherical body ...

Embodiment 2

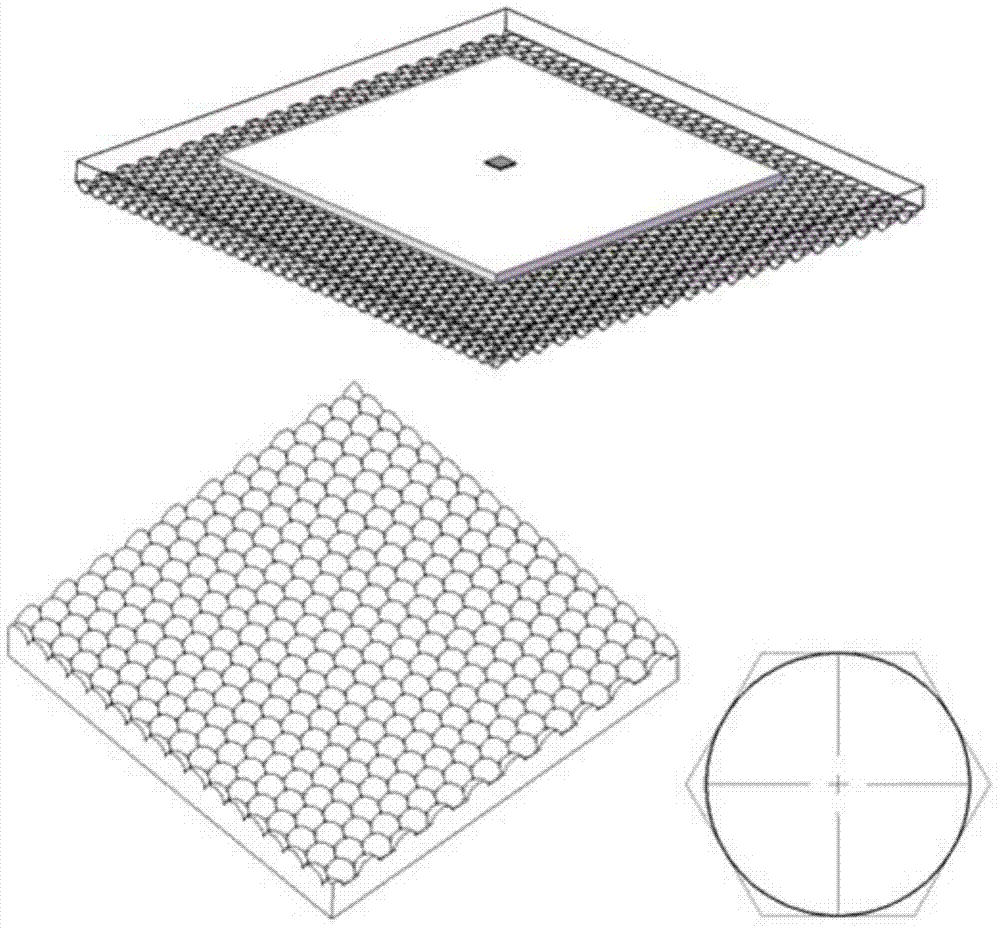

[0058] In this embodiment, a heat-dissipating glass bottom plate of a receiver for a high-power concentrating photovoltaic power generation module, the surface of the heat-dissipating glass bottom plate in contact with the air is composed of an array of curved geometric shapes arranged in a certain order. The curved body is a hemispherical body arranged regularly in a two-dimensional hexagon (that is, the hemispherical body is inscribed with the regular hexagon) to form the contact surface between the heat dissipation glass bottom plate and the air (such as image 3 mentioned).

[0059] If the side length of the square inscribed with the hemisphere is 2r,

[0060] Then the effective heat dissipation area of the hemispheroid arranged in a two-dimensional square is: S 2 =6R 2 tan30-πR 2 +2πR 2 ;

[0061] Its multiplier than the area of the base of the regular hexagon is:

[0062] The design specification of the glass backplane in this embodiment is 60x60x3.2mm, the d...

Embodiment 3

[0071] In this embodiment, a heat-dissipating glass bottom plate of a receiver for a high-power concentrating photovoltaic power generation module, the surface of the heat-dissipating glass bottom plate in contact with the air is composed of an array of curved geometric shapes arranged in a certain order. The curved body is a semi-cylindrical body, arranged in a one-dimensional order to form the contact surface between the heat dissipation glass bottom plate and the air (such as Figure 4 mentioned).

[0072] If the radius of the half cylinder is r, that is, the width of the base is 2r,

[0073] Then the effective heat dissipation area of the elongated semi-cylindrical body is S=πrL;

[0074] Its multiplier than the bottom area of the rectangle is: M=π / 2.

[0075] The design specification of the glass backplane in this embodiment is 60x60x3.2mm, the design size of the semi-cylindrical body is r=1mm, the natural convection coefficient of the air is 15 (W / ㎡*K); the chip he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com