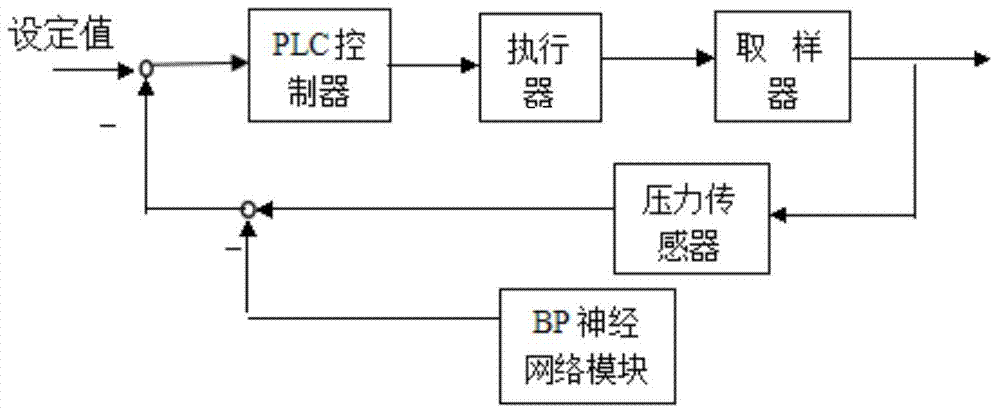

Flue fly ash constant-speed sampling device as well as flue fly ash constant-speed sampling system based on BP neural network and control method

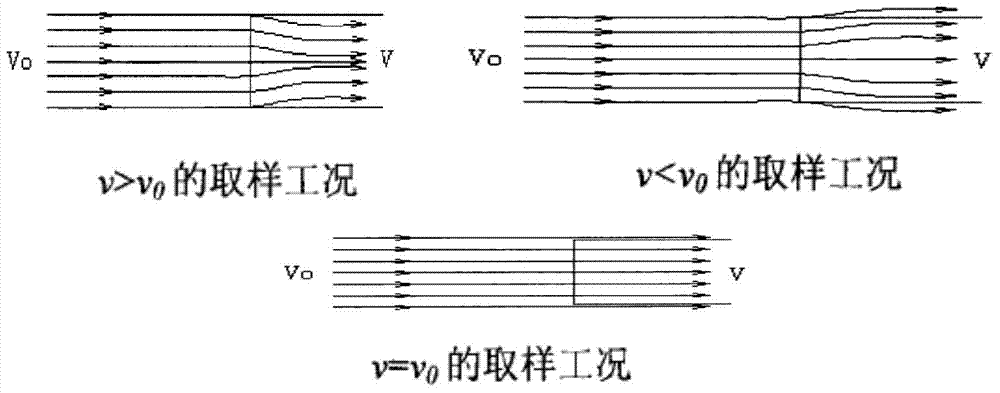

A BP neural network, isokinetic sampling technology, applied in sampling device, electrical program control, program control in sequence/logic controller, etc. The problem of low sampling accuracy is to achieve the effect of improving sampling accuracy, strong data processing ability and small calculation error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

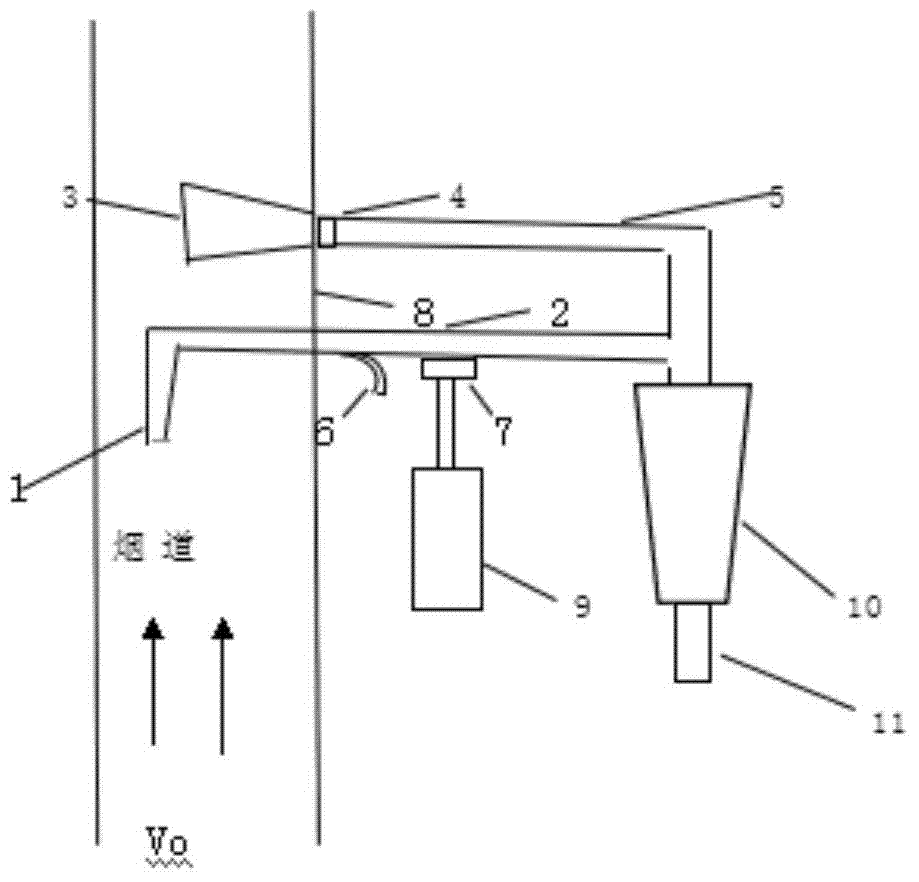

[0043] The technical scheme of the present invention is further introduced below in conjunction with accompanying drawing and specific embodiment:

[0044] Such as figure 2 , image 3 As shown, a flue fly ash constant velocity sampler includes a sampling nozzle 1, a sampling pipe 2, a cyclone separator 10 and a sampling bottle 11, and also includes an injection pipe 3, a regulating nozzle 4 and an exhaust pipe 5. The sampling nozzle 1 is located at one end of the sampling pipe 2, and the other end of the sampling pipe 2 is connected with the cyclone separator 10; the ejector pipe 3, the regulating nozzle 4 and the exhaust pipe 5 are connected in sequence; the exhaust pipe 5 is separated from the cyclone The device 10 is connected; the cyclone separator 10 is connected with the sampling bottle 11. The inside of the sampling tube is provided with a first cavity, and the inside of the sampling tube is also provided with a second cavity, and the opening of the second cavity com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com