Distributed flexible pressure sensor based on electrically active polymer

A technology of electroactive polymers and pressure sensors, which is applied in the direction of instruments, measuring force, and measuring devices, can solve the problems of lack of flexibility, inconvenient use, and difficulty in ensuring accuracy, so as to reduce external interference, reduce use costs, and reduce development costs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

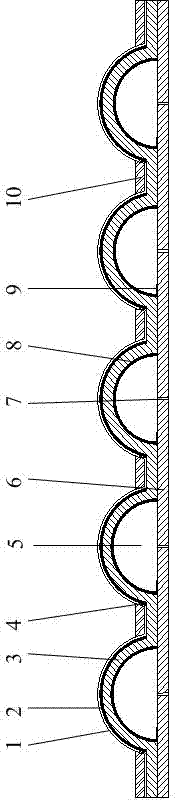

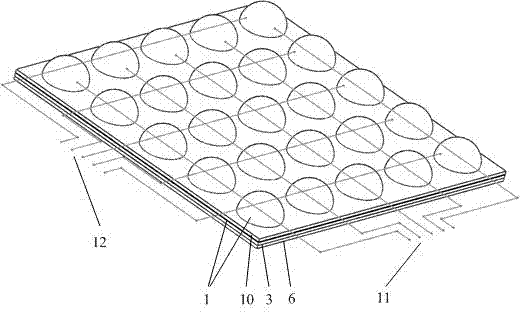

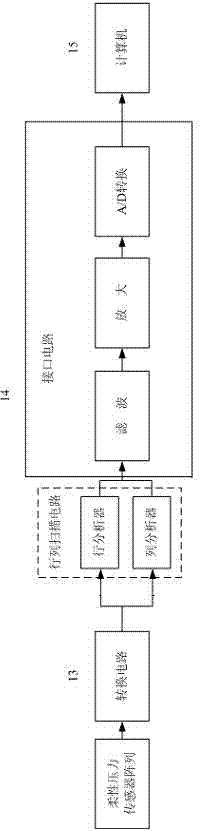

[0033] Such as Figure 1-4 shown.

[0034] A distributed flexible pressure sensor based on electroactive polymers, such as figure 1 As shown, it includes a base plate 6, an electroactive polymer 3, a first electrode layer 2, a first aluminum foil layer 4, a second electrode layer 8, a second aluminum foil layer 9, and a silicone rubber gasket 10. The thickness of the base plate 6 can be 0.001 ~2mm; the electroactive polymer 3 is bonded and sealed with the bottom plate 6, and forms a plurality of closed spaces 5 arranged in an array ( figure 2 The array in it is 5×5, which can be freely set according to the specific implementation requirements), used to achieve good contact with the measurement surface, it consists of a plurality of closed spaces 5 arranged in an array on the bottom plate 6, and the number of An air nozzle 7 that is at least equal to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com