U-shaped ring for gas generator and its manufacturing process

A gas generator, U-shaped technology, applied in the petroleum industry, engine components, engine sealing, etc., can solve problems such as difficulties, decreased U-shaped ring strength, increased production costs, etc., to solve the problem of poor stress performance and variable welding times Less, the effect of improving the precision of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

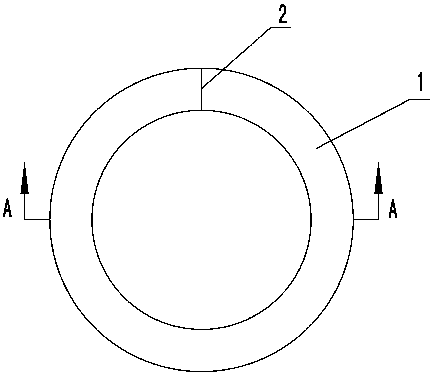

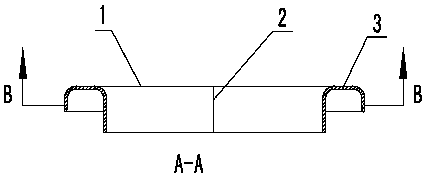

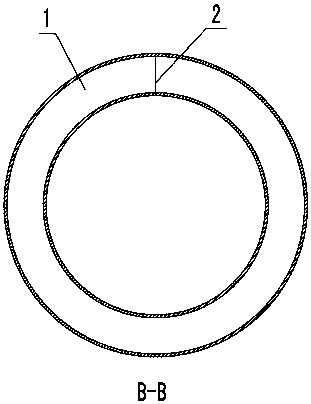

[0028] refer to Figure 1~3 , In this embodiment, the U-shaped ring is used for the gas generator, and the U-shaped ring body 1 is made of a strip-shaped steel plate made of Q235R material. The elongated steel plate is 1600 mm long, 150 mm wide, and 10 mm thick, including a U-shaped ring body 1. The U-shaped ring body 1 is annular. A weld 2 is provided on the U-shaped ring body 1. The longitudinal section 3 of the U-shaped ring body 1 is U-shaped.

[0029] refer to Figure 1~5 , the U-shaped ring for the present embodiment gas generator, its manufacturing process, comprises the following steps:

[0030] a) Select a long strip steel plate made of Q235R, use a rolling machine to roll the long strip steel plate into a plane ring, and then butt the two ends of the long strip steel plate, and weld them to form a weld 2, so that the longitudinal section is a plane The plane ring of 4;

[0031] b) Heating the planar ring 4 with a heating punch at a heating temperature of 600-1000...

Embodiment 2

[0034] refer to Figure 1~3 , In the present embodiment, the U-shaped ring is used for the gas generator, and the U-shaped ring body 1 is made of a strip-shaped steel plate made of 430 stainless steel. The strip-shaped steel plate is 1300mm long, 150mm wide, and 8mm thick. The U-shaped ring body 1 is annular, and a weld 2 is arranged on the U-shaped ring body 1. The longitudinal section 3 of the U-shaped ring body 1 is U-shaped, and the U-shaped The longitudinal section 3 is bent U-shaped.

[0035] refer to Figure 1~5 , the U-shaped ring for the present embodiment gas generator, its manufacturing process, comprises the following steps:

[0036] a) Select a long steel plate made of 430 stainless steel, and use a rolling machine to roll the long steel plate into a plane ring, then butt the two ends of the long steel plate, and weld them to form a weld 2, and obtain the longitudinal section as planar plane ring 4;

[0037] b) Heating the flat ring with a heating punch at a h...

Embodiment 3

[0040] refer to Figure 1~3 , In this embodiment, the U-shaped ring is used for the gas generator, and the U-shaped ring body 1 is made of a strip-shaped steel plate made of Q235B material. The elongated steel plate is 1800mm long, 150mm wide, and 10mm thick, including a U-shaped ring body 1, which is annular, and a weld 2 is provided on the U-shaped ring body 1, and the longitudinal section 3 of the U-shaped ring body 1 is U-shaped.

[0041] refer to Figure 1~5 , the U-shaped ring for the present embodiment gas generator, its manufacturing process, comprises the following steps:

[0042]a) Select a long strip steel plate made of Q235B material, use a rolling machine to roll the long strip steel plate into a plane ring, and then butt the two ends of the long strip steel plate, and weld them to form a weld 2, so that the longitudinal section is a plane The plane ring of 4;

[0043] b) Heating the flat ring with a heating punch at a heating temperature of 800-900°C, forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com