Cooling water tank with tail gas treatment function

A technology of exhaust gas treatment and exhaust cooling, which is applied in the direction of engine cooling, exhaust devices, mechanical equipment, etc., can solve the problems of limited installation position and large volume, and achieve the effect of ensuring the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

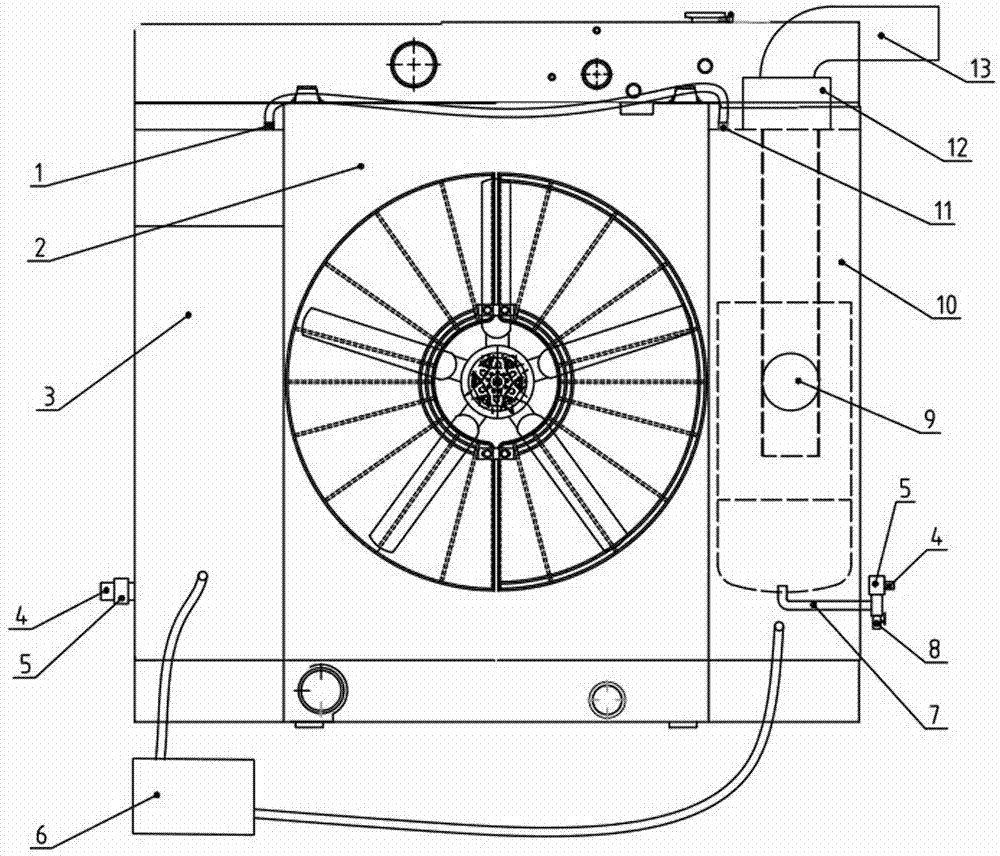

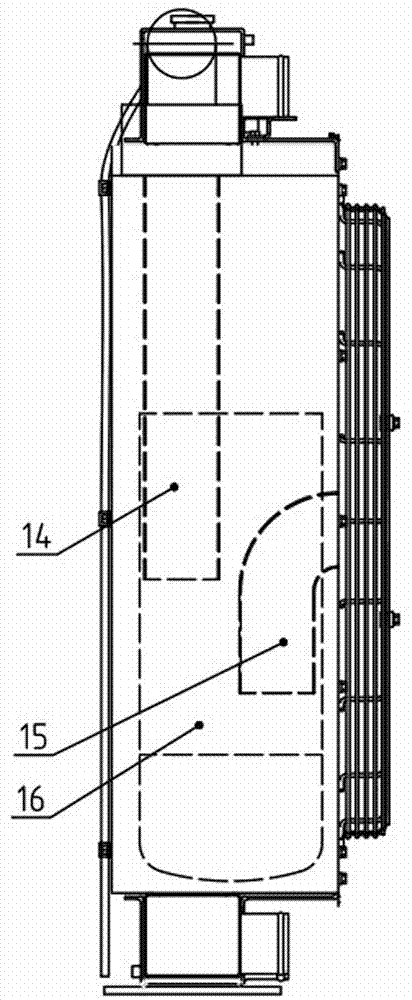

[0014] see figure 1 and figure 2 , a cooling water tank with an exhaust gas treatment function, comprising a body heat dissipation water tank 2, and an exhaust gas treatment device 10 and a water storage tank body 3 respectively arranged on both sides of the body heat dissipation water tank 2, and the exhaust gas treatment device 10 is respectively provided on the outside Exhaust gas inlet 9 and exhaust gas exhaust pipe 13 are arranged, and exhaust gas cooler is arranged inside, and described exhaust gas cooler comprises muffler inlet pipe 15, muffler 16 and muffler exhaust pipe 14, and described muffler inlet pipe 15 one end and described The exhaust gas inlet 9 is connected, and the other end is connected with the muffler 16, and the bottom of the muffler 16 is connected with a water-filled pipe 7, and the water-filled pipe 7 passes through the exhaust gas treatment device 10 and is externally connected with a water level control device, and the muffler 16 is also Connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com