Method for preparing and transferring ultrathin perforated anode alumina template

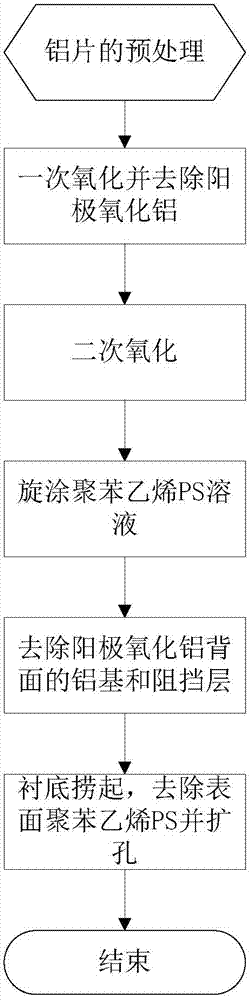

An anodized aluminum oxide transfer method technology, applied in the field of microelectronics, can solve the problems of difficult single-crystal nano-dot materials, anodized aluminum oxide templates cannot be used to prepare single-crystal nano-dot arrays, etc., to achieve uniform distribution, prevent cracking, and pore size consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

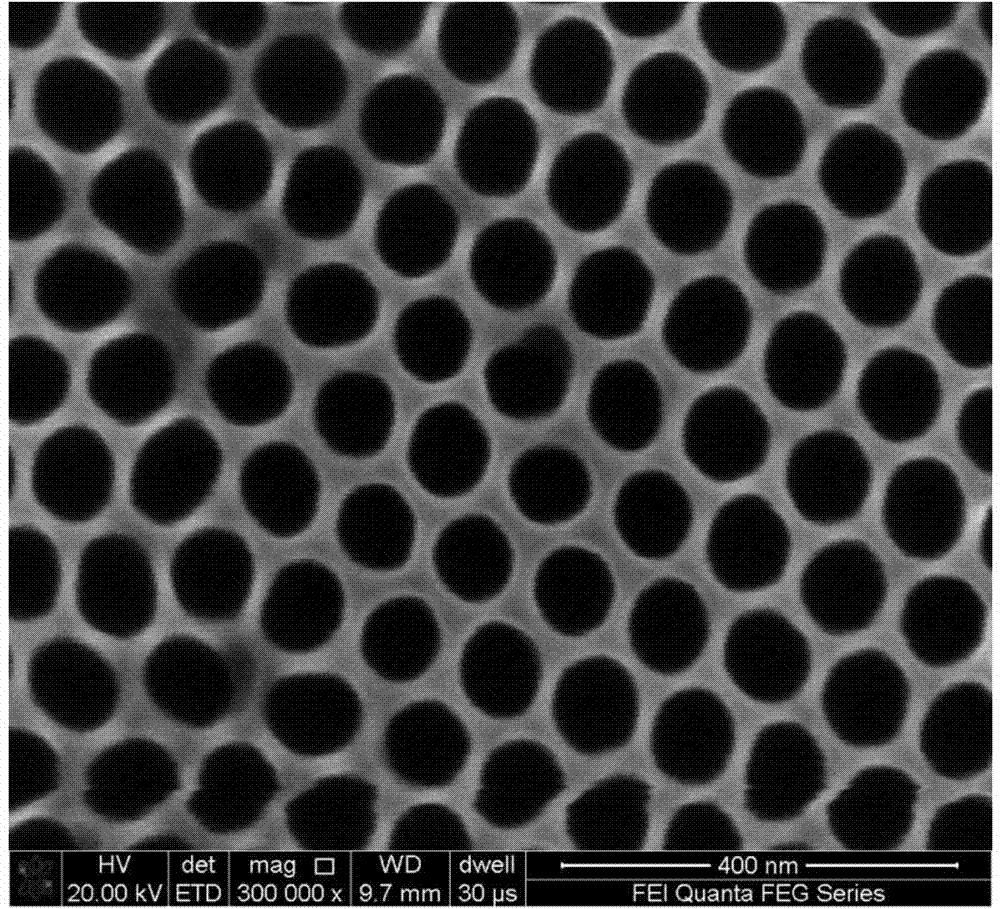

[0026] Embodiment 1: A substrate of an anodized aluminum oxide template with an ultra-thin through-hole with a pore diameter of 73nm was fabricated.

[0027] Step 1: Pre-treat the aluminum sheet.

[0028] 1a) Put the aluminum sheet with 99.999% purity into acetone, water and isopropanol solution successively and ultrasonically remove the grease on the surface for 5 minutes each;

[0029] 1b) Put the ultrasonically finished aluminum sheet into a mixed acid solution, soak it at 60°C for 30 seconds to remove impurities on the surface, the proportion of the mixed acid solution is: 20mL of concentrated hydrochloric acid, 10mL of concentrated nitric acid, 1mL of hydrofluoric acid , water 69mL;

[0030] 1c) Put the aluminum sheet from which surface impurities have been removed into the polishing solution, and polish it at 20V for 4 minutes in constant voltage mode to make the aluminum sheet smooth. The polishing solution is composed of 25mL perchloric acid stock solution and 75mL ab...

Embodiment 2

[0049] Embodiment 2: A substrate of an anodized aluminum oxide template with an ultra-thin through-hole with a pore diameter of 76nm was fabricated.

[0050] Step A: Pretreat the aluminum flakes.

[0051] A1) Put the aluminum sheet with 99.999% purity into acetone, water and isopropanol solution successively and ultrasonically remove the grease on the surface for 7 minutes each;

[0052] A2) Put the ultrasonically finished aluminum sheet into a mixed acid solution, soak it at 60°C for 32 seconds to remove impurities on the surface, the ratio of the mixed acid solution is: concentrated hydrochloric acid 20mL, concentrated nitric acid 10mL, hydrofluoric acid 1mL , water 69mL;

[0053] A3) Put the aluminum sheet from which surface impurities have been removed into the polishing solution, and polish it at 20V for 4 minutes and 30 seconds in constant voltage mode to make the aluminum sheet smooth. The polishing solution is composed of 25mL perchloric acid stock solution and 75mL ...

Embodiment 3

[0070] Embodiment 3: A substrate of an anodized aluminum oxide template with an ultra-thin through-hole with a pore diameter of 79nm was fabricated.

[0071] Step 1, pretreating the aluminum sheet.

[0072] First put the 99.999% pure aluminum sheet into acetone, water and isopropanol solutions for 10 minutes to remove the surface grease; then put the aluminum sheet after ultrasonication into the mixed acid solution and soak it at 60°C The impurities on the surface are removed in 35 seconds. The ratio of the mixed acid solution is: 20mL of concentrated hydrochloric acid, 10mL of concentrated nitric acid, 1mL of hydrofluoric acid, and 69mL of water. Polish at 20V for 5 minutes to make the aluminum sheet flat. The polishing solution is mixed with 25mL of perchloric acid stock solution and 75mL of absolute ethanol.

[0073] Step 2: Oxidize the pretreated aluminum sheet by constant voltage direct current mode.

[0074] First put the polished aluminum sheet into the oxalic acid so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com