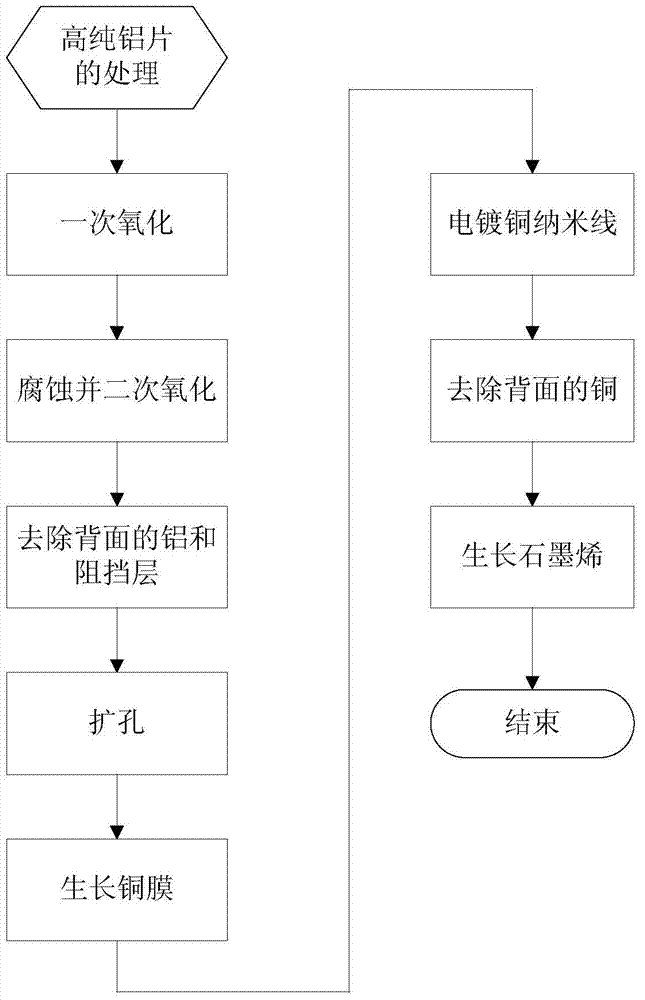

Large-area graphene preparing method based on high-density ordered copper nanowire catalyst

A copper nanowire, high-density technology, applied in the field of microelectronics, can solve the problem of difficulty in preparing large-area graphene, and achieve the effect of uniform pore size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

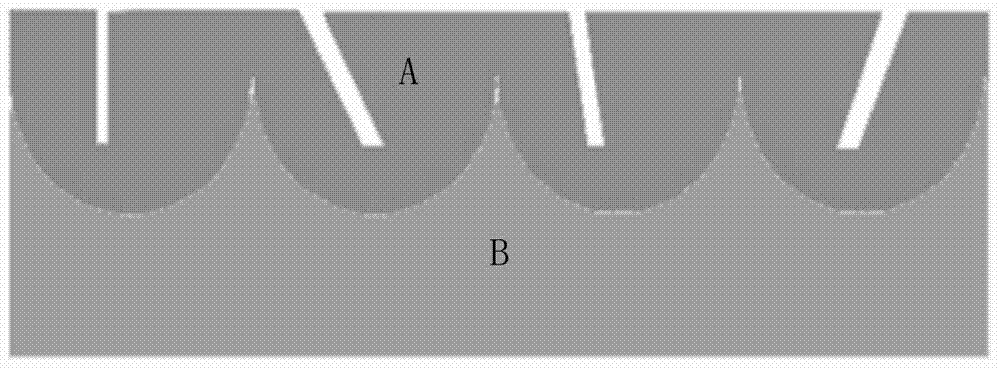

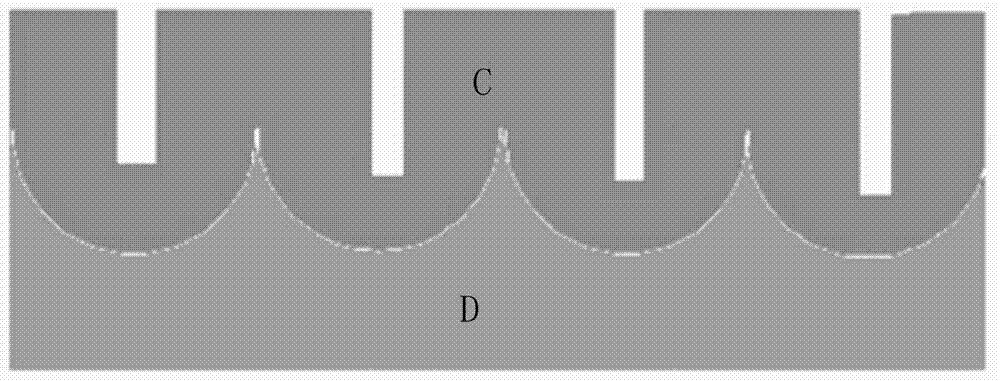

[0030] Embodiment 1: Making graphene catalyzed based on copper nanowires with a length of 10 um.

[0031] Step 1: Pre-treat the aluminum sheet.

[0032] (1a) Put the aluminum sheet with 99.999% purity into acetone, water and isopropanol solution successively, and ultrasonically remove the grease on the surface for 5 minutes each;

[0033] (1b) Put the ultrasonically finished aluminum sheet into a mixed acid solution and soak it at 60°C for 30 seconds to remove surface impurities. 1mL, water 69mL;

[0034] (1c) Put the aluminum sheet from which surface impurities have been removed into the polishing solution, and polish it at 20V for 4 minutes in constant voltage mode to make the aluminum sheet smooth. The polishing solution is composed of 25mL perchloric acid stock solution and 75mL anhydrous mixed with ethanol.

[0035] Step 2: Oxidize the pretreated aluminum sheet using constant voltage direct current mode.

[0036] (2a) Put the polished aluminum sheet into an oxalic aci...

Embodiment 2

[0051] Embodiment 2: Making graphene catalyzed based on copper nanowires with a length of 15 um.

[0052] The first step: pretreatment of aluminum sheet.

[0053] (A1) Put the aluminum flakes with 99.999% purity into acetone, water and isopropanol solutions and ultrasonically remove the grease on the surface for 7 minutes each;

[0054] (A2) Put the ultrasonically finished aluminum sheet into a mixed acid solution and soak it at 60°C for 32 seconds to remove surface impurities. 1mL, water 69mL;

[0055] (A3) Put the aluminum sheet that has removed surface impurities into the polishing solution, and polish it at 20V for 4 minutes and 30 seconds in constant voltage mode to make the aluminum sheet smooth. The polishing solution is composed of 25mL perchloric acid stock solution and 75mL mixed with ethanol.

[0056] Step 2: Oxidize the pretreated aluminum sheet using constant voltage direct current mode.

[0057] (B1) primary oxidation, put the polished aluminum sheet into an ...

Embodiment 3

[0072] Embodiment 3: Making graphene catalyzed based on copper nanowires with a length of 20 um.

[0073] Step 1, pretreating the aluminum sheet.

[0074] First put the 99.999% pure aluminum sheet into acetone, water and isopropanol solutions for 10 minutes to remove the surface grease; then put the aluminum sheet after ultrasonication into the mixed acid solution and soak it at 60°C The impurities on the surface are removed in 35 seconds. The ratio of the mixed acid solution is: 20mL of concentrated hydrochloric acid, 10mL of concentrated nitric acid, 1mL of hydrofluoric acid, and 69mL of water. Polish at 20V for 5 minutes to make the aluminum sheet flat. The polishing solution is mixed with 25mL of perchloric acid stock solution and 75mL of absolute ethanol.

[0075] Step 2: Oxidize the pretreated aluminum sheet by constant voltage direct current mode.

[0076] Put the polished aluminum sheet into the oxalic acid solution with a concentration of 0.5mol / L, and soak it for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com