Spring steel material for elevator and preparation method of spring steel material

A spring steel and elevator technology, applied in the field of spring steel materials and their preparation, can solve problems such as the performance decline of spring steel and loss of effective components, and achieve the effects of reducing quenching cracking, uniform performance, and improving toughness and elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

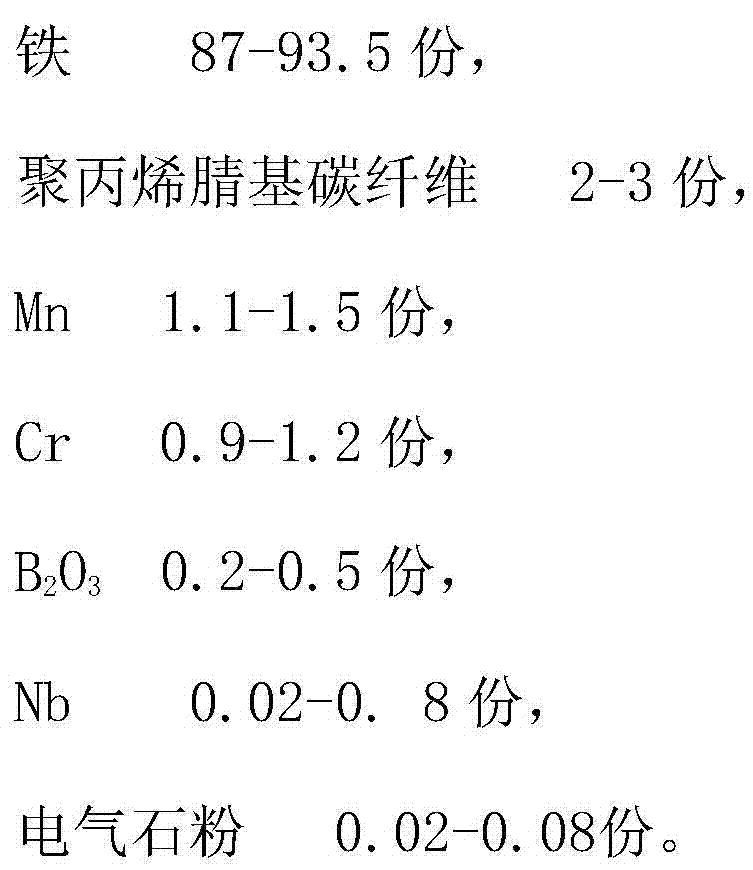

[0027] (1) Iron powder 87kg, Mn1.1kg, Cr 0.9kg, B 2 o 3 0.2kg, Nb0.02kg and tourmaline powder 0.02kg, add water, put into ball mill for ball milling, dry, press into block under 10Mpa pressure, then sinter at 90℃ for 2 hours under nitrogen protection atmosphere, the sintered The material is crushed and passed through a 250-mesh sieve;

[0028] (2) 2 kg of polyacrylonitrile-based carbon fibers with a diameter of 8.9 microns are added to the product of step (1), heated at 65° C., and mixed uniformly at a speed of 500 rpm;

[0029] (3) Put the mixture in step (2) into a mold, press it into a compact, place the compact in a sintering furnace, heat up to 400°C at a rate of 20°C / min and sinter for 2 hours;

[0030] (4) The product in step (3) was sintered at a rate of 10°C / min to 1075°C for 1 hour, and finally placed in air and cooled to room temperature to obtain a spring steel material for elevators.

[0031] The performance test results of the prepared spring steel materials a...

Embodiment 2

[0033] (1) Iron powder 87kg, Mn1.5kg, Cr 0.9kg, B 2 o 3 0.5kg, Nb0.02kg and tourmaline powder 0.02kg, add water, put into ball mill for ball milling, dry, press into block under 10Mpa pressure, then sinter at 900℃ for 2 hours under nitrogen protection atmosphere, the sintered The material is crushed and passed through a 250-mesh sieve;

[0034] (2) 2 kg of polyacrylonitrile-based carbon fibers with a diameter of 8.9 microns are added to the product of step (1), heated at 65° C., and mixed uniformly at a speed of 500 rpm;

[0035] (3) Put the mixture in step (2) into a mold, press it into a compact, place the compact in a sintering furnace, heat up to 400°C at a rate of 20°C / min and sinter for 2 hours;

[0036] (4) The product in step (3) was sintered at a rate of 10°C / min to 1075°C for 1 hour, and finally placed in air and cooled to room temperature to obtain a spring steel material for elevators.

[0037] The performance test results of the prepared spring steel materials ...

Embodiment 3

[0039] (1) Iron powder 93.5kg, Mn1.5kg, Cr 1.2kg, B 2 o 3 0.5kg, Nb0.8kg, tourmaline powder 0.08kg, La 2 o 3 1.1kg and sodium metasilicate 0.1kg, add water, put into ball mill for ball milling, dry, press into block under 12Mpa pressure, and then sinter at 1000℃ for 3 hours under nitrogen protection atmosphere, crush the sintered material Pass through a 300-mesh sieve;

[0040] (2) 3 kg of polyacrylonitrile-based carbon fibers with a diameter of 7.1 microns were added to the product of step (1), heated at 55° C., and mixed uniformly at a speed of 600 rpm;

[0041] (3) Put the mixture in step (2) into a mold, press it into a compact, place the compact in a sintering furnace, heat up to 400°C at a rate of 20°C / min and sinter for 1 hour;

[0042] (4) The product in step (3) was sintered at a rate of 10°C / min to 1160°C for 1.5 hours, and finally placed in air and cooled to room temperature to obtain a spring steel material for elevators.

[0043] The performance test results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com