Method for manufacturing high magnetic induction grain-oriented silicon steel through short-process medium and thin slab

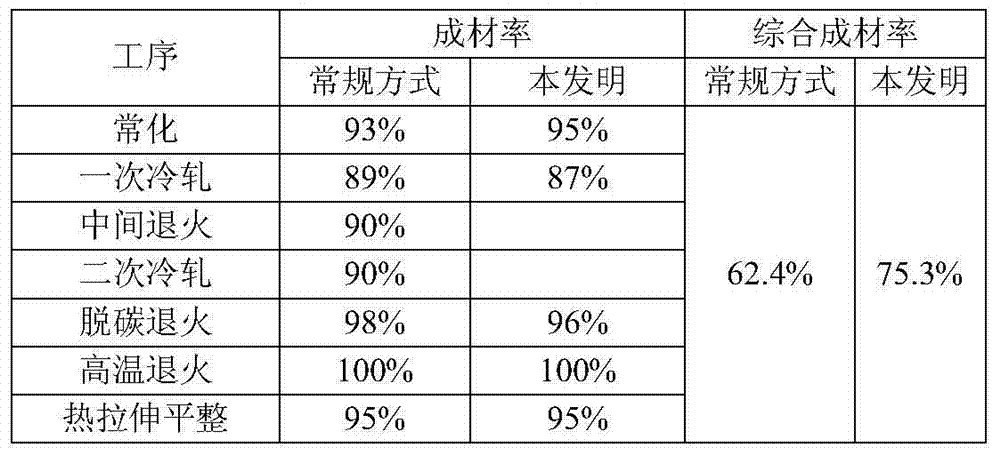

A high magnetic induction orientation, medium-thin slab technology, applied in the field of iron and steel metallurgy, can solve the problems of increased cost, difficulty in obtaining, and surface defects of slabs, so as to improve production efficiency and yield, increase continuous casting cooling speed, comprehensive Effect of Yield Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1.1 Composition

[0031] A can of steel is smelted, and its chemical composition is shown in Table 2.

[0032] Table 2 Chemical Composition (wt%)

[0033] the element

C

Si

mn

P

S

als

N

content

0.03

2.9

0.08

0.005

0.02

0.01

0.006

[0034] 1.2 Process

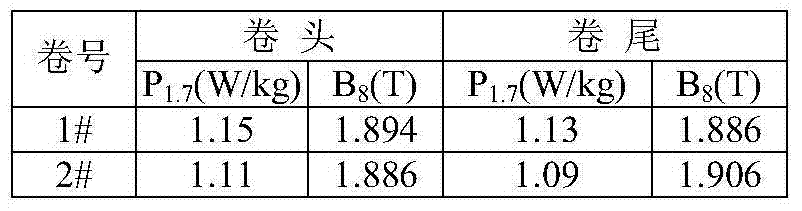

[0035] The LF furnace is used for refining outside the furnace, the medium and thin slabs are continuously cast and rolled, the casting speed is 1.6m / min, and the thickness of the continuous casting slab is 120mm. The furnace loading temperature of the slab is 400°C, the heating temperature is 1100°C, the first roughing mill is rolled for 3 passes, the second roughing mill is rolled for 1 pass, the thickness of the intermediate slab is 35mm, and the finishing rolling temperature is 1080°C, the thickness of the hot-rolled sheet is 2.0mm, and the coiling temperature is 500°C. Select 2 coils of steel (1#, 2#), the first stage of normalization i...

Embodiment 2

[0069] 4.1 Composition

[0070] The chemical composition is shown in Table 9.

[0071] Table 9 chemical composition (wt%)

[0072] the element

C

Si

mn

P

S

als

N

content

0.05

3.4

0.20

0.018

0.010

0.02

0.010

[0073] 4.2 Process

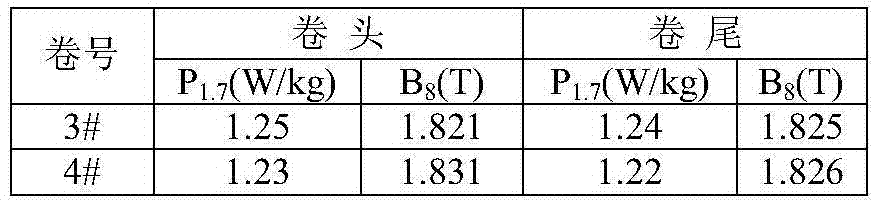

[0074] Using LF refining outside the furnace, the medium and thin slab continuous casting and rolling process is implemented, the continuous casting casting speed is 2.0m / min, the continuous casting slab thickness is 150mm, the slab charging temperature is 350°C, and the hot rolling heating temperature is 1230°C. The first rough rolling mill is rolled for 3 passes, the second rough rolling mill is rolled for 1 pass, the thickness of the intermediate billet is 30mm, the temperature of entering and finishing rolling is 1060°C, and the thickness of the hot-rolled plate is 2.5mm; select 2 coils of raw materials (5#, 6#), the first stage of the normalization process is heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com