Fur free formaldehyde content reducing method

A technology of free formaldehyde content and free formaldehyde, applied in the field of leather, can solve problems such as the release pattern that cannot be completely targeted, and achieve the effect of strong wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

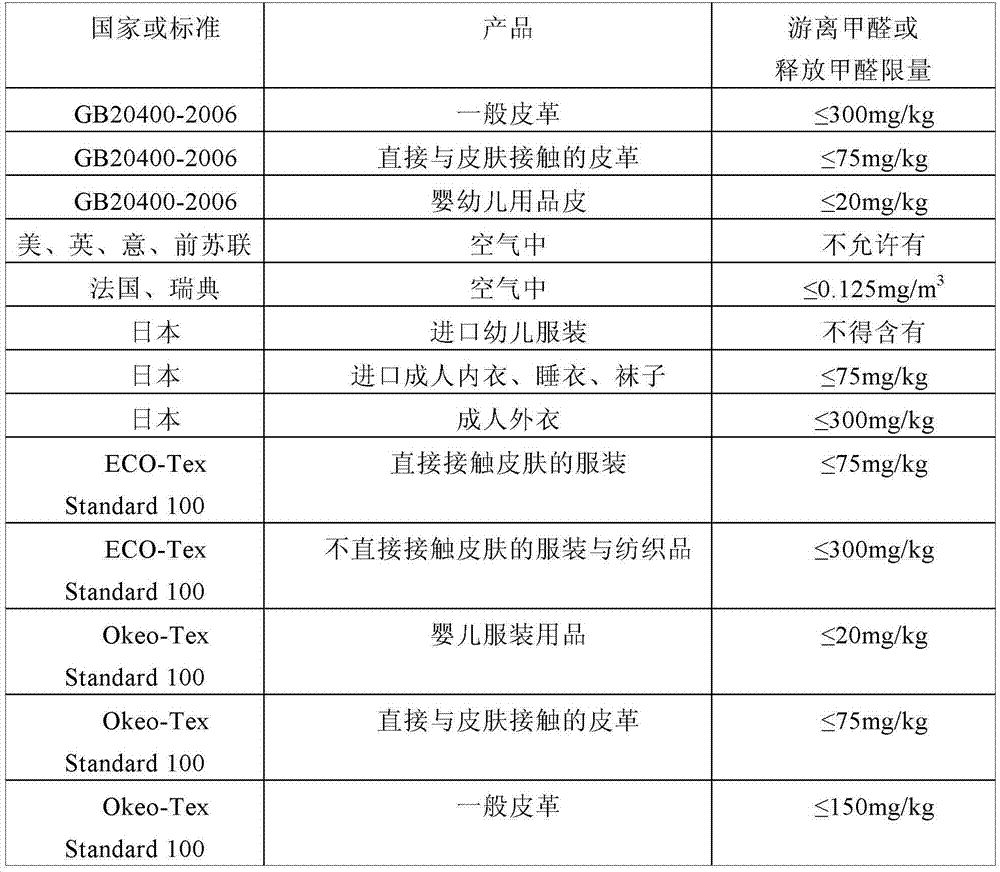

Problems solved by technology

Method used

Image

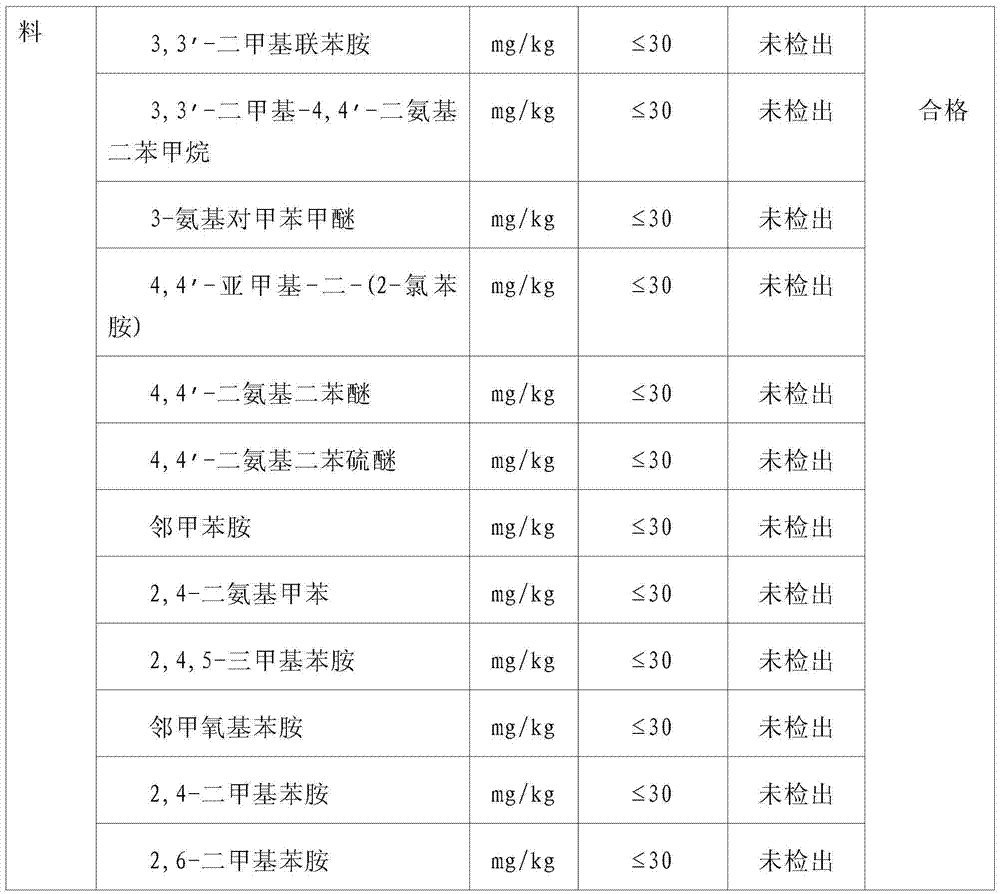

Examples

Embodiment 1

[0069] Retanning, dyeing and dealdehyde process of rabbit fur

[0070] 1) Rabbit fur is about 50kg, and the free formaldehyde content is determined to be 458.93mg / kg.

[0071] 2) Retanning, dealdehyde

[0072] Equipment: 1000L trough, ratio of water to fur liquid: 20 (mass ratio), temperature 35°C, industrial salt: (main component sodium chloride) 40g / L, formic acid: 0.5g / L, ammonium alum 5g / L, powder Chromium tanning agent (HLS-C of Brother Technology Co., Ltd., with a basicity of 33% and a content of 25% of chromium trioxide): 15g / L.

[0073] Operation: After adjusting the water temperature and water volume, add industrial salt and formic acid, paddle evenly, remove the skin, paddle for 30 minutes, add ammonium alum and chrome tanning agent, paddle for 60 minutes. After 5 minutes every hour, after 4 hours, add soda ash: 2-3g / L (dissolve soda ash with water 10 times the amount of soda ash, add it in three times, add once every 30 minutes), after 30 minutes, use a pH meter t...

Embodiment 2

[0102] Retanning, dyeing and dealdehyde process of raccoon fur

[0103] 1) About 50kg of raccoon fur, free formaldehyde content 661mg / KG.

[0104] 2) Retanning, dealdehyde

[0105] Equipment: 1000L trough, ratio of water to fur liquid: 20 (mass ratio), temperature 35°C, industrial salt: (main component sodium chloride) 40g / L, formic acid: 0.5g / L, ammonium alum 7g / L, powder Chromium tanning agent (HLS-C of Brother Technology Co., Ltd., with a basicity of 33% and a content of 25% of chromium trioxide): 13g / L.

[0106] Operation: After adjusting the water temperature and water volume, add industrial salt and formic acid, paddle evenly, remove the skin, paddle for 30 minutes, add ammonium alum and chrome tanning agent, paddle for 60 minutes. After 5 minutes every hour, after 4 hours, add soda ash: 3g / L (dissolve soda ash with water 10 times the amount of soda ash, add it in three times, add once every 30 minutes), after 30 minutes, use a pH meter to measure pH = 3.8 -4.0, when ...

Embodiment 3

[0121] Natural color raccoon fur retanning and dealdehyde process

[0122] 1) About 50kg of raccoon fur, the free formaldehyde content determined by the enterprise is 442.11mg / kg

[0123] 2) Retanning, dealdehyde

[0124] Equipment: 1000L trough, ratio of water to fur liquid: 20 (mass ratio), temperature 35°C, industrial salt: (main component sodium chloride) 40g / L, formic acid: 0.5g / L, ammonium alum 7g / L, powder Chromium tanning agent (HLS-C of Brother Technology Co., Ltd., 33% basicity, 25% chromium trioxide content): 13g / L.

[0125] Operation: After adjusting the water temperature and water volume, add industrial salt and formic acid, paddle evenly, remove the skin, paddle for 30 minutes, add ammonium alum and chrome tanning agent, paddle for 60 minutes. After 5 minutes every hour, after 4 hours, add soda ash: 3g / L (dissolve soda ash with water 10 times the amount of soda ash, add it in three times, add once every 30 minutes), after 30 minutes, use a pH meter to measure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com