Preparation method of novel PVC-bamboo-plastic composite material

A composite material and bamboo-plastic technology, applied in the field of preparation of new PVC bamboo-plastic composite materials, can solve the problems of poor flame retardant performance, deformation, performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

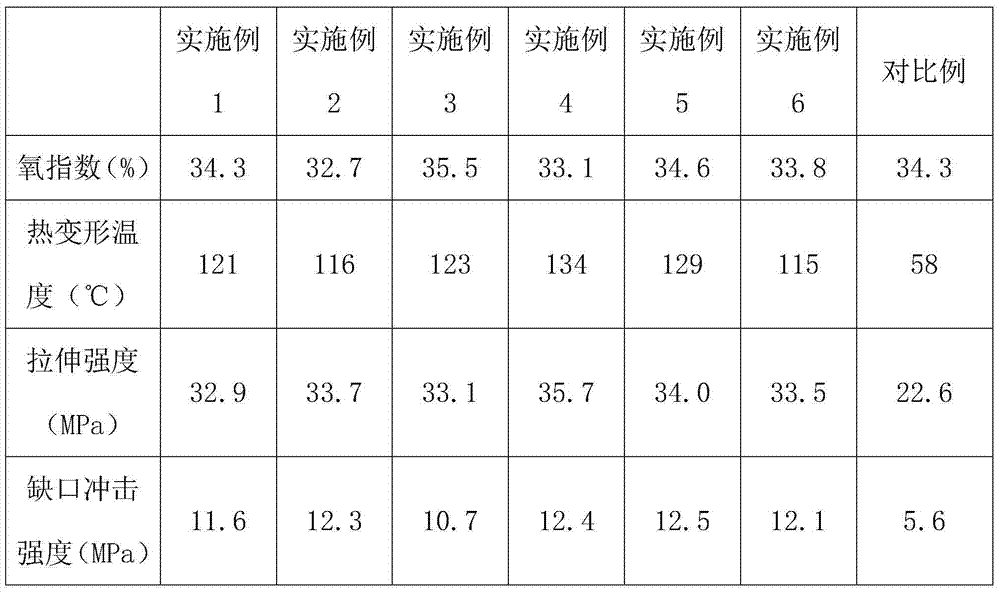

Examples

Embodiment 1

[0025] A kind of preparation method of novel PVC bamboo-plastic composite material, its step is as follows:

[0026] (1) Add aniline and formaldehyde together into a three-port reaction kettle for stirring in a water bath, add bisphenol A after 50 minutes and start heating, heat to 110°C after 1 hour, and remove the reflux device after 1.5 hours of heat preservation and reflux reaction, dehydration under reduced pressure, The vacuum degree during the decompression dehydration is -0.1MPa, and the reaction is stopped when the material system no longer produces bubbles, and the benzoxazine resin is obtained after the discharge is cooled to room temperature for subsequent use, wherein the molar ratio of aniline, formaldehyde, and bisphenol A is 1:2:1;

[0027] (2) Add the boric acid ester coupling agent into absolute ethanol, after completely dissolving, add magnesium borate whiskers and stir at 60°C for 20 minutes, add azobisisobutyronitrile under nitrogen protection and continue...

Embodiment 2

[0031] A kind of preparation method of novel PVC bamboo-plastic composite material, its step is as follows:

[0032] (1) Add aniline and formaldehyde together into a three-port reaction kettle for stirring in a water bath, add bisphenol A after 50 minutes and start heating, heat to 110°C after 1 hour, and remove the reflux device after 1.5 hours of heat preservation and reflux reaction, dehydration under reduced pressure, The vacuum degree during the decompression dehydration is -0.1MPa, and the reaction is stopped when the material system no longer produces bubbles, and the benzoxazine resin is obtained after the discharge is cooled to room temperature for subsequent use, wherein the molar ratio of aniline, formaldehyde, and bisphenol A is 1:2:1;

[0033] (2) Add the boric acid ester coupling agent into absolute ethanol, after completely dissolving, add magnesium borate whiskers and stir at 60°C for 20 minutes, add azobisisobutyronitrile under nitrogen protection and continue...

Embodiment 3

[0037] A kind of preparation method of novel PVC bamboo-plastic composite material, its step is as follows:

[0038] (1) Add aniline and formaldehyde together into a three-port reaction kettle for stirring in a water bath, add bisphenol A after 50 minutes and start heating, heat to 110°C after 1 hour, and remove the reflux device after 1.5 hours of heat preservation and reflux reaction, dehydration under reduced pressure, The vacuum degree during the decompression dehydration is -0.1MPa, and the reaction is stopped when the material system no longer produces bubbles, and the benzoxazine resin is obtained after the discharge is cooled to room temperature for subsequent use, wherein the molar ratio of aniline, formaldehyde, and bisphenol A is 1:2:1;

[0039] (2) Add the boric acid ester coupling agent into absolute ethanol, after completely dissolving, add magnesium borate whiskers and stir at 60°C for 20 minutes, add azobisisobutyronitrile under nitrogen protection and continue s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com